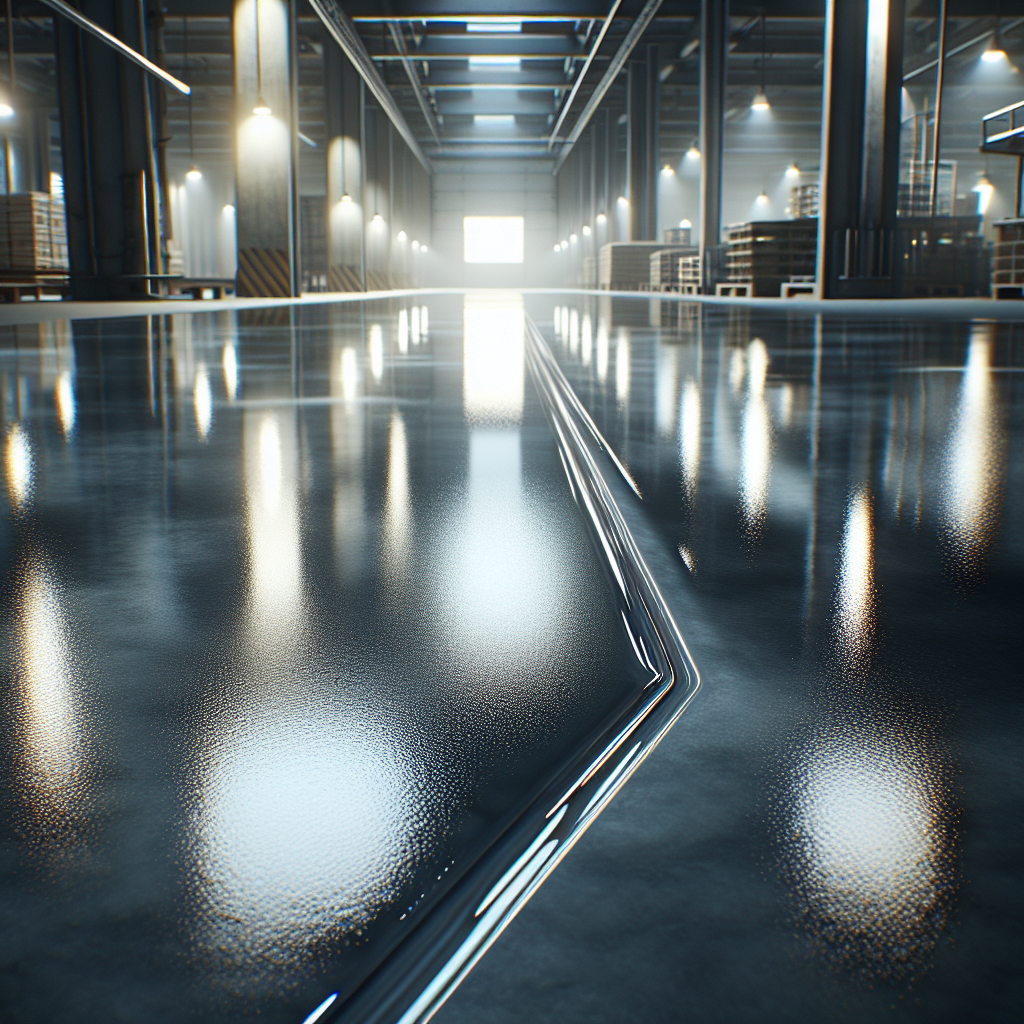

When it comes to creating an *exceptionally durable* and visually appealing floor surface, epoxy flooring stands out as a popular choice. However, to enhance both the **longevity** and **aesthetic appeal** of epoxy floors, applying the right top coat is crucial. A top coat not only adds an extra layer of protection but also brings out the best in the epoxy’s appearance, ensuring it remains in pristine condition for years to come.

Epoxy floor top coats are designed to shield the surface from scratches, stains, and other forms of damage that daily wear and tear can cause. They are vital for maintaining the floor’s **shine** and **resilience**, especially in high-traffic areas such as garages, warehouses, and industrial spaces. By sealing the surface, top coats prevent moisture penetration and chemical spills from compromising the floor’s integrity.

Depending on the environment and specific needs, various types of top coats can be used, including urethane, polyaspartic, and acrylic. Each option offers unique benefits, such as **UV protection**, **increased hardness**, or **faster curing times**. Selecting the best top coat for your epoxy floor involves understanding these differences and matching them with the floor’s intended use.

For those in Broward County, Florida, who are looking to enhance their epoxy floors with a high-quality top coat, Americas Industrial Coatings in Fort Lauderdale offers expert services. Call Us Today for a Free Quote and discover how we can help you achieve the perfect epoxy finish.

Importance of Choosing the Right Top Coat

Selecting the **appropriate top coat** for your epoxy floor is a decision that holds significant weight in ensuring the floor’s performance and longevity. The right top coat acts as a shield, protecting the underlying epoxy layer from environmental stressors such as moisture, UV rays, and chemical spills. This protective barrier is particularly crucial in industrial settings, where floors are exposed to harsh conditions.

Moreover, the correct top coat can enhance the floor’s aesthetic qualities, making your space more inviting and professional. For example, a high-gloss top coat can accentuate the colors and patterns of the epoxy, creating a **sleek and reflective surface**. Conversely, a matte finish can offer a more subtle elegance, reducing glare and providing a softer look.

Beyond aesthetics, the right top coat contributes to safety by providing slip resistance, especially in areas prone to spills or wet conditions. This is a critical feature for maintaining a safe environment for both workers and visitors.

It’s important to consider the specific requirements of your space when choosing a top coat. Factors such as **foot traffic**, **exposure to sunlight**, and the presence of chemicals should guide your selection. By aligning the top coat’s properties with your floor’s needs, you can maximize both the functionality and lifespan of your epoxy flooring.

Types of Top Coats for Epoxy Floors

When it comes to epoxy floors, there are several **types of top coats** available, each offering distinct advantages tailored to specific needs. Understanding these options can help you make an informed decision that best suits your flooring requirements.

Polyurethane Top Coats: Known for their exceptional durability and resistance to abrasion, polyurethane top coats are ideal for high-traffic areas. They offer excellent UV stability, making them perfect for spaces with ample sunlight exposure. Additionally, polyurethane top coats provide a flexible finish that can withstand impacts, ensuring your epoxy floor remains intact under pressure.

Polyaspartic Top Coats: These are renowned for their rapid curing time, allowing for quicker project completion. Polyaspartic top coats deliver a robust, weather-resistant finish that can withstand extreme temperatures, making them suitable for both indoor and outdoor applications. Their versatility and quick drying time make them a popular choice among professionals.

Epoxy Top Coats: While epoxy is typically used as a base, it can also serve as a top coat, providing a seamless and glossy finish. Epoxy top coats are highly resistant to chemicals and stains, making them ideal for environments prone to spills, such as garages or industrial kitchens.

Choosing the right type of top coat involves considering the specific demands of your space, such as exposure to sunlight, temperature variations, and the level of foot or vehicular traffic. By aligning these factors with the properties of the top coat, you can enhance both the **durability and appearance** of your epoxy floors.

Factors to Consider When Selecting a Top Coat

Choosing the right top coat for your epoxy floor is crucial to ensure both longevity and aesthetic appeal. There are several **factors to consider** that can guide your decision-making process and help you select the most suitable product for your needs.

Durability: One of the primary considerations should be the level of durability required for your space. High-traffic areas, such as commercial spaces or garages, demand a top coat that can withstand wear and tear, while residential settings might not need the same level of robustness.

UV Resistance: If your epoxy floor is exposed to sunlight, UV resistance becomes a key factor. Top coats with UV stabilizers prevent yellowing and degradation, maintaining the floor’s appearance over time. Polyurethane and polyaspartic top coats often excel in this area.

Chemical Resistance: In environments prone to spills or exposure to chemicals, selecting a top coat with strong chemical resistance is essential. This is particularly important in industrial settings or areas like kitchens and garages.

Application Time: The time available for the application and curing process can also influence your choice. Polyaspartic top coats, for instance, cure quickly, which is beneficial for projects with tight deadlines.

Aesthetic Preferences: Lastly, consider the visual finish you desire. Whether you prefer a glossy, matte, or textured appearance, different top coats offer varied finishes that can enhance the overall look of your epoxy floor.

Evaluating these factors will ensure that you select a top coat that not only meets your functional requirements but also complements the aesthetic vision for your space. By doing so, you can enjoy the benefits of a well-protected and visually appealing epoxy floor.

Application Tips for Epoxy Floor Top Coats

Applying a top coat to your epoxy floor is a crucial step that enhances both the *durability* and *appearance* of the surface. To achieve the best results, consider these **application tips** that can help ensure a smooth and long-lasting finish.

Surface Preparation: Begin with thorough surface preparation. Ensure the epoxy base is clean, dry, and free from any dust or debris. Any imperfections or contaminants can affect the adhesion and final appearance of the top coat. **Sanding** the epoxy surface lightly can improve adhesion.

Environmental Conditions: Pay attention to the environmental conditions during application. Ideal conditions often include a temperature range of 60°F to 85°F with low humidity. These conditions facilitate proper curing and help prevent issues like bubbling or uneven drying.

Mixing Instructions: Follow the manufacturer’s instructions meticulously when mixing the top coat components. Improper mixing can lead to inconsistent performance or finish. Use a clean mixing tool and ensure that the mixture is homogeneous before application.

Application Technique: Utilize a high-quality roller or squeegee for even application. Starting from the farthest corner of the room, work your way towards the exit to avoid stepping on the freshly applied coat. Apply the top coat in thin, even layers for the best results.

Curing Time: Allow adequate curing time as specified by the manufacturer. Avoid foot traffic and placing any objects on the floor until the top coat has fully cured to prevent any damage to the surface.

By following these tips, you can ensure that your epoxy floor’s top coat is applied effectively, enhancing both its performance and aesthetic appeal. A well-applied top coat adds a protective layer that helps your floor withstand daily wear and tear while maintaining its pristine appearance.

Maintaining Your Epoxy Floor Finish

Maintaining your epoxy floor finish is essential to preserve its *shine* and *durability*. With proper care, your epoxy floor can look as good as new for many years. Here are some **maintenance tips** to keep your floor in top condition:

Regular Cleaning: Sweep or vacuum the floor regularly to remove dust and debris. Use a soft-bristle broom or a vacuum with a brush attachment to prevent scratches. For a deeper clean, mopping with a mild detergent and warm water will help maintain the floor’s luster.

Avoid Harsh Chemicals: Avoid using harsh chemicals or abrasive cleaners, as they can damage the epoxy finish. Instead, opt for a pH-neutral cleaner that is safe for epoxy surfaces.

Address Spills Promptly: While epoxy is resistant to many substances, it’s important to clean spills immediately to prevent staining or slipping hazards. Use a soft cloth or mop to blot spills and rinse the area with water.

Use Protective Pads: Place protective pads under furniture legs to avoid scratching or damage when moving items. This simple step can prevent unnecessary wear and extend the life of your floor.

Regular Inspection: Periodically inspect your floor for any signs of damage or wear. Addressing minor issues early can prevent more significant problems and help maintain the overall integrity of the floor.

By incorporating these maintenance practices, you can ensure your epoxy floor remains in pristine condition, enhancing both its functionality and aesthetic appeal. Investing time in proper maintenance will pay off in the long run, keeping your space looking professional and inviting.

Call Us Today for a Free Quote to learn more about maintaining and enhancing your epoxy floor. Visit us at Americas Industrial Coatings for expert advice and services.