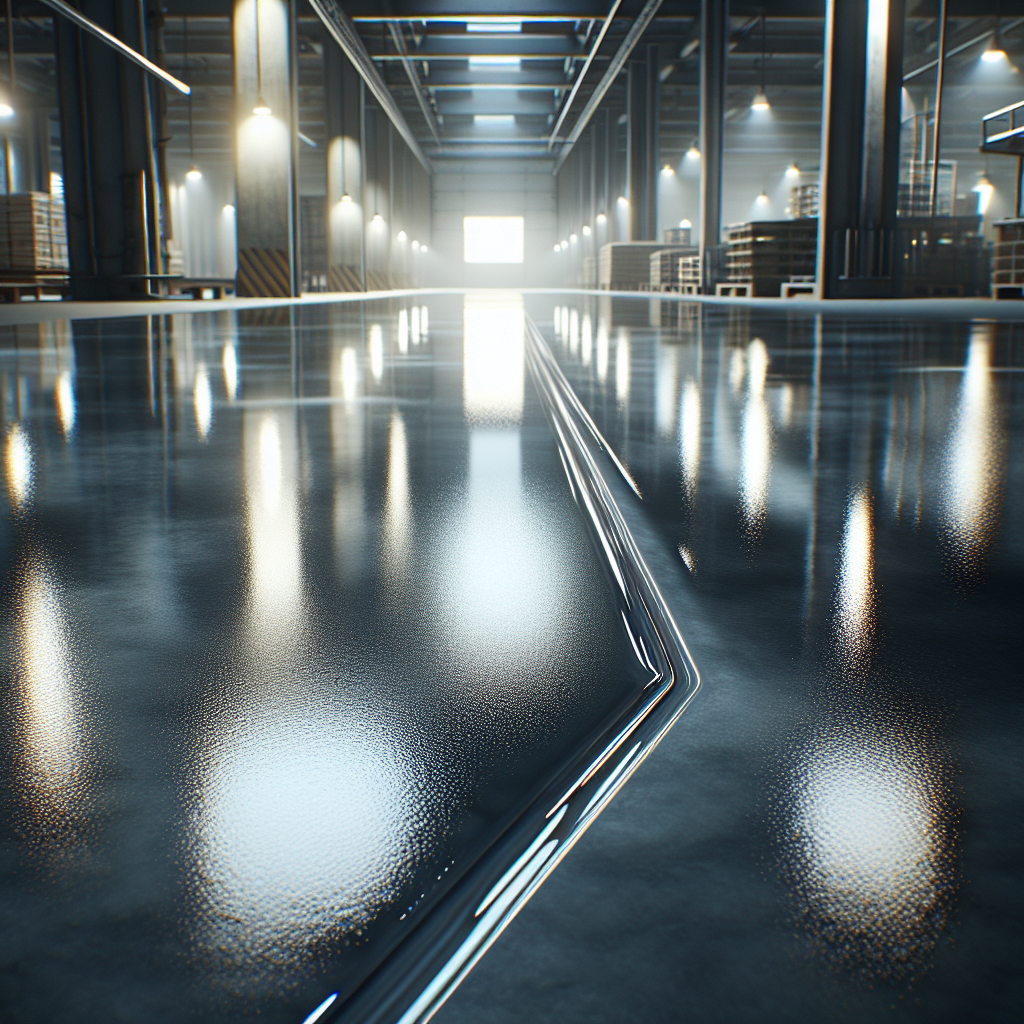

If you’re considering an upgrade to your garage in Fort Myers, FL, look no further than epoxy garage floors. These floors have gained immense popularity due to their durability, ease of maintenance, and visual appeal. An epoxy floor is a seamless surface created by applying multiple layers of epoxy, which is a thermosetting resin, over concrete. The result is a hardened, chemical-resistant surface that can withstand heavy traffic and resist stains from oil, chemicals, and other spills commonly found in garages.

In addition to their robustness, epoxy floors offer a wide range of design options, allowing homeowners to choose from various colors, patterns, and finishes. This means you can personalize your garage floor to match your style or even coordinate it with the rest of your home. The reflective surface of epoxy also enhances lighting within the garage, making it a brighter and more inviting space.

Whether you’re looking to protect your existing concrete slab or seeking to transform your garage into a more functional and aesthetically pleasing area, epoxy flooring is an excellent choice. It is a long-term investment that not only boosts the value of your home but also enhances your daily living experience by turning your garage into a space you’ll love to use.

**Call Us Today for a Free Quote** and discover how epoxy garage floors can revolutionize your home in Fort Myers, FL. Visit Americas Industrial Coatings for more information.

Benefits of Epoxy Flooring for Garages

When it comes to revamping your garage, choosing epoxy flooring offers numerous advantages that go beyond mere aesthetics. One of the most significant benefits is its extreme durability. Epoxy floors can withstand heavy loads, making them ideal for garages where vehicles, tools, and equipment are frequently stored and moved. This resilience ensures that your flooring will remain intact for years, even under stressful conditions.

Another advantage is the resistance to stains and chemicals. Garages are prone to spills from oil, gasoline, and other substances. Epoxy floors resist these stains, maintaining their pristine appearance and simplifying cleanup. This feature makes them incredibly low-maintenance, as they can be easily wiped clean with a simple mop or broom.

Epoxy flooring also provides enhanced safety features. Its slip-resistant surface reduces the risk of accidents, especially in environments where spills and moisture are common. Some epoxy coatings can even be enhanced with additional additives to increase this non-slip property, offering peace of mind for homeowners.

Furthermore, epoxy floors can improve the overall look and feel of your garage. Available in a variety of colors and finishes, they offer the flexibility to create a unique and visually appealing space. Whether you prefer a sleek, modern look or something more traditional, epoxy can be customized to suit your style, ultimately transforming your garage into a more welcoming and functional area.

Epoxy Floor Installation Process

Understanding the installation process of epoxy flooring can help in appreciating the transformation it brings to your garage. The process begins with the preparation of the concrete surface, which is crucial for ensuring a strong bond between the epoxy and the floor. This involves thorough cleaning to remove dirt, grease, and any existing coatings, followed by repairing cracks and imperfections in the concrete.

Once the surface is clean and smooth, the next step is the application of a primer coat. This layer helps to seal the concrete and enhances the adhesion of the epoxy. After the primer is applied, it is allowed to cure before proceeding to the next stage.

The core of the process is the application of the epoxy coating. This involves mixing the epoxy resin with a hardener, which starts the chemical reaction leading to the hardening of the material. The mixture is then applied evenly across the garage floor using specialized tools, ensuring a consistent layer. Depending on the desired thickness and finish, multiple coats may be applied, with each layer needing time to cure before the next is added.

For those seeking a more decorative finish, optional additives such as colored flakes or metallic pigments can be included during the application. These not only enhance the visual appeal but also add texture to the floor.

After the final coat is applied, a protective topcoat is often added. This topcoat serves to increase the floor’s resistance to wear and UV damage, extending the longevity of your investment. With proper installation and curing, typically spanning a few days, an epoxy floor can transform your garage into a durable and attractive space.

Design Options for Epoxy Garage Floors

One of the most compelling aspects of epoxy garage floors is the wide array of design options they offer. Whether you prefer a sleek and modern look or a more artistic and personalized design, epoxy floors can be customized to suit your taste and the overall aesthetic of your home.

Solid color finishes are a popular choice for those seeking a clean and uniform appearance. These finishes provide a high-gloss look that can enhance the brightness of your garage space. For a more dynamic appearance, consider metallic epoxy coatings. These create a shimmering, three-dimensional effect that mimics the appearance of flowing metals or natural stone, adding a touch of luxury to your garage.

If you want to incorporate patterns or textures, decorative flakes can be added to the epoxy mix. These flakes come in various sizes and colors, allowing for a random yet cohesive design that also enhances slip resistance. For a truly unique floor, you might opt for a quartz-filled epoxy, which combines the durability of epoxy with the beauty and texture of natural quartz granules.

For those who wish to make a bold statement, custom logos or images can be embedded within the epoxy layers. This option is great for car enthusiasts who want to showcase their favorite brand or for businesses looking to incorporate their logo into the flooring.

Ultimately, the design flexibility of epoxy garage floors means you can create a space that is not only functional but also an extension of your personal style. The possibilities are endless, making it a popular choice for homeowners in Fort Myers, FL.

Maintenance Tips for Epoxy Garage Floors

Maintaining your epoxy garage floor in Fort Myers, FL, is essential to preserve its durability and aesthetic appeal. Fortunately, one of the key benefits of epoxy flooring is its low maintenance requirements. However, a few simple practices can ensure your floor remains in top condition for years to come.

Firstly, it’s important to regularly sweep or vacuum the floor to remove dust and debris. This prevents particles from scratching the surface and keeps your garage looking clean. For deeper cleaning, a mild detergent mixed with water can be used. Avoid using harsh chemicals or abrasive cleaning tools, as these can damage the epoxy finish.

Spills should be wiped up promptly to prevent staining. Although epoxy floors are resistant to most stains, substances like oil or paint can leave marks if left unattended for long periods. Using a soft cloth or mop to clean spills ensures that the surface remains unblemished.

It’s also advisable to place mats or rugs in high-traffic areas, such as entry points or workstations. These can help absorb dirt and prevent minor scratches. If your garage sees frequent vehicle traffic, consider using protective mats under tires to distribute weight and prevent indentations.

Lastly, periodic inspection of your epoxy floor can help identify any areas that may need touch-ups or resealing. Keeping an eye on the condition of your floor ensures that it continues to provide a safe and visually appealing surface.

By following these simple maintenance tips, you’ll enjoy the lasting beauty and functionality of your epoxy garage floor, making it a valuable addition to your home.

Choosing the Right Epoxy Floor Installer

Selecting the right epoxy floor installer is crucial to ensuring a successful and long-lasting application in your Fort Myers garage. With numerous contractors available, it’s essential to conduct thorough research to find a professional who meets your specific needs. Here are some key considerations to help you make an informed choice.

Firstly, look for an installer with a strong reputation and extensive experience in epoxy flooring. A seasoned professional will not only have a portfolio of completed projects but will also be able to provide references from satisfied clients. Checking online reviews and testimonials can give you insight into the quality of their work and customer service.

Next, ensure that the installer uses high-quality materials and up-to-date techniques. This is vital for demanding environments like garages, where durability and resistance to spills, chemicals, and heavy traffic are essential. Ask potential installers about the types of epoxy they use and the methods they employ to guarantee a robust finish.

Additionally, obtain detailed quotes from multiple installers. This will help you compare not only pricing but also the scope of services offered. Be wary of quotes that seem too low, as they may indicate compromises on material quality or craftsmanship. A transparent, itemized estimate reflects professionalism and clarity.

Finally, a reliable installer should provide a warranty or guarantee on their work, giving you peace of mind that any potential issues will be addressed promptly.

When you’re ready to transform your garage with an expertly installed epoxy floor, call us today for a free quote at Americas Industrial Coatings. Our team in Fort Myers, FL, is committed to delivering exceptional service and results that exceed your expectations.