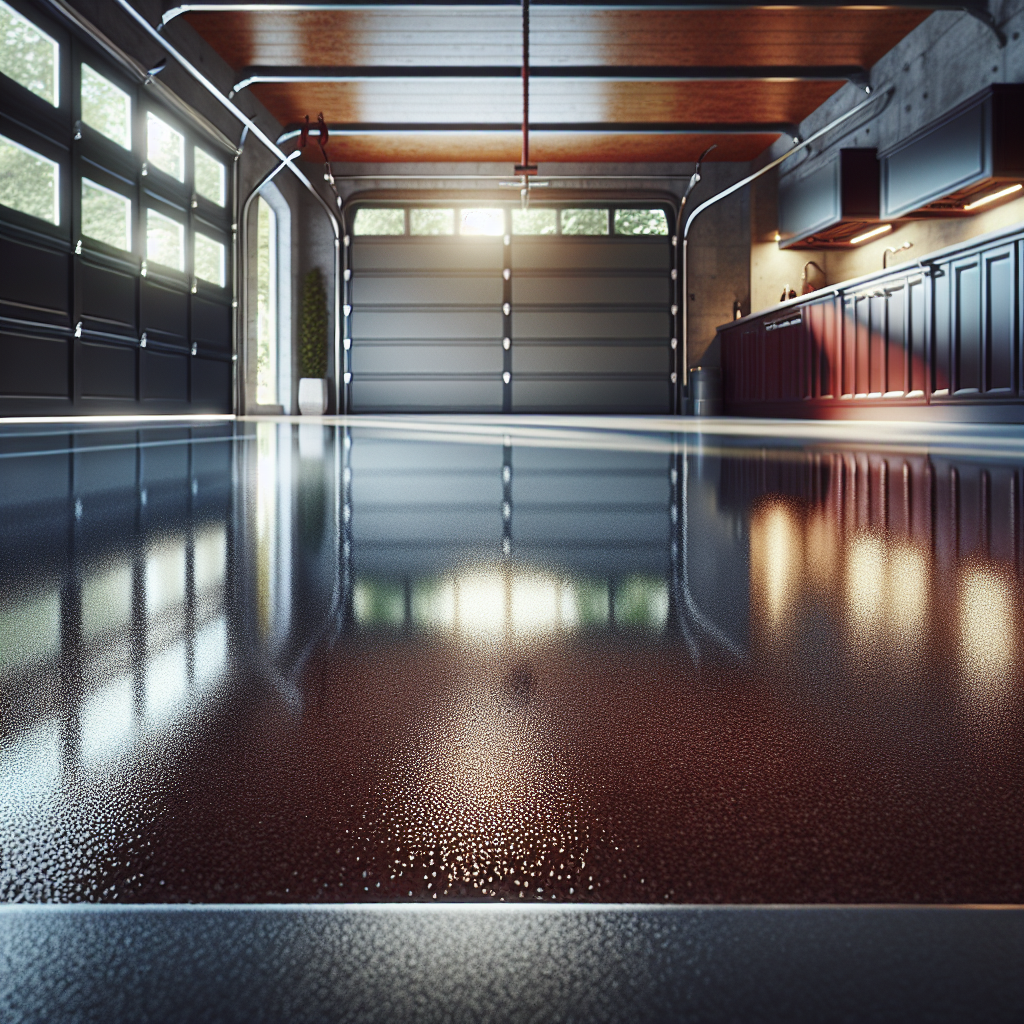

When it comes to enhancing the durability and aesthetic appeal of garage floors, **epoxy coatings** have become the go-to solution for professionals across the globe. Their ability to withstand heavy traffic, resist stains, and offer a seamless finish makes them a preferred choice for both residential and commercial garages. But what exactly makes professional-grade epoxy stand out?

The secret lies in the composition and application techniques that professionals employ. **High-quality epoxy** is typically a two-part system comprising a resin and a hardener. Once mixed, these components undergo a chemical reaction that results in a rigid plastic material, providing a robust and long-lasting floor surface. Professionals often choose epoxies with added fillers or pigments to meet specific needs such as increased hardness, enhanced color, or improved slip-resistance.

Understanding the types of epoxy that professionals use can help homeowners make informed decisions when upgrading their garage spaces. Professional installers often favor **100% solid epoxy** due to its superior strength and longevity. Unlike water-based or solvent-based epoxies, 100% solid epoxy contains no volatile organic compounds (VOCs), making it an environmentally friendly choice.

For those looking to transform their garage floors with the expertise of high-quality epoxy applications, it’s vital to work with experienced professionals who understand the nuances of epoxy formulations and installation techniques. Get started on your garage transformation today by reaching out to experts who can tailor solutions to your unique needs. Call Us Today for a Free Quote and take the first step towards a durable and beautiful garage floor.

Types of Epoxy Used by Professionals

Professionals have a variety of epoxy types at their disposal, each catering to specific needs and preferences. **100% solids epoxy** is one of the most popular choices due to its durability and robust finish. It contains no solvents, which means it doesn’t evaporate during curing, resulting in a thicker and more resilient coating. This type of epoxy is ideal for high-traffic areas, offering exceptional protection against wear and tear.

Another commonly used type is **water-based epoxy**, which is easier to apply and more forgiving during installation. While it may not be as durable as 100% solids epoxy, it is an excellent choice for DIY projects or areas with less foot traffic. Water-based epoxy also emits fewer odors and harmful fumes, making it a more environmentally friendly option.

**Solvent-based epoxy** is another variant, known for its excellent bonding properties and chemical resistance. Although it can provide a glossy finish, the presence of solvents means it emits strong odors and requires adequate ventilation during application. This type is often used in commercial settings where chemical resistance is paramount.

Professionals also employ **metallic epoxy coatings**, which are increasingly popular for those seeking a decorative touch. These coatings include metallic pigments that create a unique, marbled effect, adding a touch of sophistication to any garage space. Despite their aesthetic appeal, they maintain the fundamental protective qualities of epoxy, making them both practical and visually striking.

Understanding these options allows homeowners to select the right type of epoxy for their garage, ensuring both functionality and style are achieved. Each type of epoxy offers unique benefits, and professionals can guide you in choosing the best option for your specific needs and environment.

Benefits of Professional Grade Epoxy

Opting for **professional grade epoxy** comes with a multitude of benefits that elevate the functionality and aesthetics of garage floors. One of the most significant advantages is its *exceptional durability*. Professional grade epoxy is formulated to withstand heavy loads, making it ideal for garages that house vehicles, tools, and heavy machinery. Its robust nature ensures that the floor remains resistant to chips, cracks, and other forms of damage.

Another key benefit is its **chemical resistance**. Garages often come into contact with various substances like oil, gasoline, and other chemicals that can damage ordinary floors. Professional grade epoxy protects against these corrosive agents, preserving the floor’s integrity and appearance over time. This resistance makes it easier to maintain a clean and safe environment, as spills can be easily wiped away without leaving stains.

Moreover, professional epoxy offers an **increased aesthetic appeal**. With its glossy finish and the ability to incorporate various colors and patterns, epoxy transforms a dull garage into a vibrant, visually appealing space. The reflective property of epoxy enhances lighting in the garage, making it a more inviting and safer environment to work in.

Additionally, professional grade epoxy provides a **seamless and non-porous surface**, which is crucial for easy maintenance. Dust, dirt, and debris are less likely to accumulate, reducing the time and effort required for cleaning. This seamless nature also minimizes the risk of mold and bacteria growth, promoting a healthier environment.

Overall, professional grade epoxy combines functionality with style, offering a long-lasting solution for garage floors that is both practical and visually appealing. Its myriad benefits make it a worthwhile investment for any homeowner looking to enhance their garage space.

How to Choose the Right Epoxy

Selecting the **right epoxy** for your garage floor can make a world of difference in terms of durability and appearance. When choosing epoxy, there are several factors to consider to ensure that you get the most out of your investment. Understanding these elements will help you make an informed decision that aligns with your needs and expectations.

First and foremost, consider the **intended use of your garage**. If your garage is frequently used for heavy-duty activities, such as housing large vehicles or machinery, you’ll need an epoxy with high durability and load-bearing capacity. Look for products that are labeled as heavy-duty or industrial grade to ensure they can withstand the demands of your space.

Next, evaluate the **environmental conditions**. If your garage is exposed to extreme temperatures or moisture, it’s crucial to select an epoxy that offers excellent resistance to these conditions. Epoxies with added UV protection or moisture barriers can prevent damage and preserve the floor’s integrity over time.

Color and finish are also important considerations. **Aesthetic preferences** can guide your choice, but also think about practical aspects like light reflection. A high-gloss finish can brighten up the space, making it more functional and visually appealing. Alternatively, a matte finish can provide a more subdued look that’s equally stylish.

Additionally, take into account the **application process**. Some epoxies are more user-friendly and can be applied with simple tools, while others may require professional installation for optimal results. Understanding your own skill level and the complexity of the product will help you decide whether to DIY or hire a professional.

Finally, always review the **product’s warranty and support**. A reputable epoxy product should come with a comprehensive warranty and customer support to address any issues that may arise during or after installation.

By considering these factors, you can choose an epoxy that not only meets your functional needs but also enhances your garage’s overall appeal.

Application Tips from Professionals

Applying epoxy to your garage floor can seem daunting, but with the right tips from **professionals**, you can achieve a flawless finish. Proper preparation and technique are key to ensuring a long-lasting and visually appealing epoxy floor.

Start with thorough **surface preparation**. Professionals emphasize that this is the most critical step in the entire process. The garage floor must be clean, dry, and free from any contaminants such as oil, grease, or dust. Use a degreaser and a power washer to remove stubborn stains and debris. If your floor has any cracks or chips, repair them with a suitable filler and ensure the surface is smooth and level.

Next, ensure that the **floor is completely dry** before applying the epoxy. Moisture can prevent the epoxy from adhering properly, leading to blistering or peeling. To test for moisture, tape a plastic sheet to the floor and leave it for 24 hours. If the area under the plastic is dry, you’re ready to proceed.

When mixing the **epoxy components**, accuracy is crucial. Follow the manufacturer’s instructions closely to ensure the correct ratio of resin to hardener. Mixing mistakes can lead to curing issues, so take your time and use a power drill with a mixing paddle for a consistent blend.

Apply the epoxy systematically. Start from the farthest corner of the garage and work your way towards the exit to avoid stepping on the wet epoxy. Professionals advise using a roller for even application, and a brush for edges and corners. Be mindful of the pot life—the time you have before the epoxy starts to harden—and work efficiently within this timeframe.

Finally, allow adequate **curing time**. Depending on the product, this could range from a few hours to several days. Avoid walking or driving on the floor until it’s fully cured to prevent any indentations or marks.

By following these expert tips, you can achieve a professional-grade epoxy floor that enhances the durability and aesthetics of your garage.

Maintaining Your Epoxy Garage Floor

Once your epoxy garage floor is installed, maintaining it is key to preserving its durability and appearance. **Regular maintenance** not only keeps your floor looking pristine but also extends its lifespan, ensuring you get the most out of your investment.

Start with routine **cleaning**. Sweep or vacuum the floor regularly to remove dust and debris that can cause scratches. For a deeper clean, mop the floor with a mix of water and a mild detergent. Avoid harsh chemicals or abrasive cleaners that can damage the epoxy’s glossy finish.

Address **spills and stains** promptly. While epoxy is resistant to many substances, it’s a good practice to clean spills immediately to prevent any potential staining or chemical damage. Use a soft cloth or mop to wipe away spills, and for tougher stains, a gentle scrub with a soft brush should suffice.

Place mats or rugs at entrances to reduce the amount of dirt and moisture that gets tracked onto the floor. This simple step can significantly reduce the wear and tear on your epoxy surface.

Inspect your floor periodically for any signs of **damage**. Small chips or cracks should be repaired quickly to prevent them from worsening. Most minor damages can be fixed with an epoxy repair kit, ensuring your floor remains seamless and intact.

By following these maintenance tips, your epoxy garage floor will continue to look and function at its best for years to come. If you’re considering an epoxy floor installation or need advice on maintenance, Call Us Today for a Free Quote. Our experts at Americas Industrial Coatings are here to help you achieve and maintain the perfect garage floor.