Understanding epoxy flooring begins with recognizing its basic components. Epoxy flooring is renowned for its durability, aesthetic appeal, and versatility, making it a preferred choice for both residential and commercial spaces. But what exactly is epoxy flooring made of? By delving into its core components, we can appreciate why it stands out as a leading flooring solution.

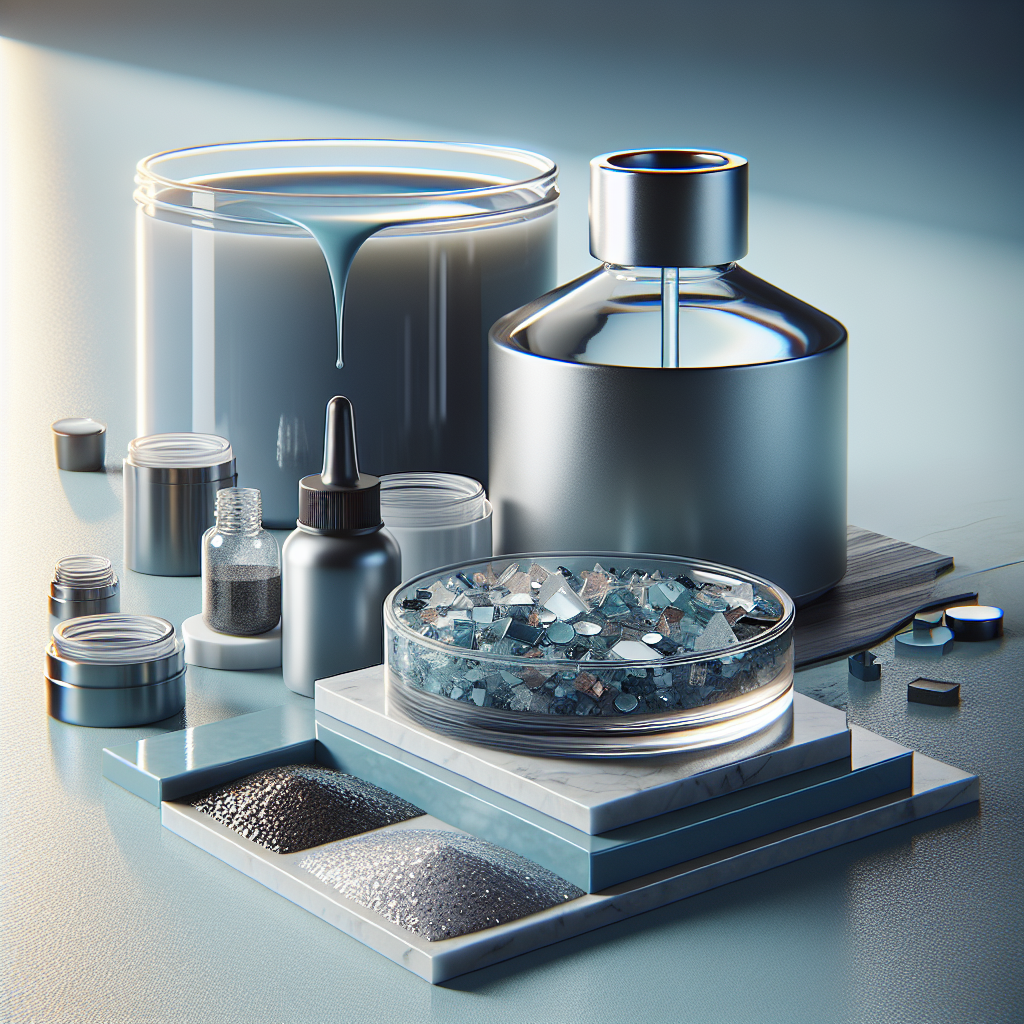

At its heart, epoxy flooring is a combination of resins and hardeners. When these two elements are mixed, they chemically react to form a rigid plastic material. This resulting compound is highly resistant to wear, chemical spills, and impact, providing a robust solution for high-traffic areas. The resin is the primary binding agent, often a clear or colored viscous liquid, while the hardener acts as a catalyst that solidifies the resin into a durable surface.

Beyond these foundational components, various additives can be included to enhance the floor’s properties. For instance, pigments can be added for color, while decorative flakes or chips can provide texture and aesthetic appeal. Additionally, anti-slip additives are often incorporated to improve safety, especially in commercial or industrial settings.

If you’re considering epoxy flooring for your space, understanding these components can help you make an informed decision tailored to your specific needs. Call Us Today for a Free Quote to learn more about how we can bring the benefits of epoxy flooring to your environment. Visit us at Americas Industrial Coatings for expert guidance and installation services.

Understanding Epoxy Resin and Hardeners

The foundation of any epoxy floor lies in the interplay between epoxy resin and hardeners. These two components must be mixed in precise ratios to achieve the desired strength and durability. The epoxy resin, typically a clear or colored viscous liquid, serves as the primary binding agent that will later form a solid, resilient surface.

The hardener, on the other hand, is what activates the resin. When the two are combined, a chemical reaction occurs, transforming the liquid mixture into a hard, plastic-like material. This process is called curing, and it is crucial for the formation of a sturdy and long-lasting floor. The specific type of hardener used can significantly influence the properties of the finished epoxy floor, such as its cure time, mechanical strength, and resistance to environmental factors.

Different formulations of resins and hardeners can be tailored to meet diverse requirements. For example, some applications might require faster curing times, while others might prioritize greater chemical resistance or enhanced flexibility. Understanding these variations is key to selecting the right type of epoxy for your flooring needs.

Additionally, the ratio of resin to hardener is vital; incorrect proportions can lead to issues such as improper curing, reduced durability, or uneven surfaces. Thus, professional installation is often recommended to ensure the optimal performance of your epoxy floor.

Role of Aggregates in Epoxy Floors

Aggregates play a pivotal role in enhancing both the functionality and aesthetics of epoxy floors. These materials, which can include sand, quartz, or decorative chips, are incorporated into the epoxy mixture or broadcast over the surface before curing. Their primary function is to add texture, improve durability, and provide additional slip resistance, making the floor safer and more resilient to wear and tear.

By incorporating aggregates, the visual appeal of epoxy flooring can be significantly enhanced. For instance, colored quartz or decorative flakes can be used to create a terrazzo-like appearance, offering an attractive finish that can be customized to fit any design preference. This makes epoxy floors not only practical but also versatile in terms of aesthetics, suitable for both industrial environments and decorative settings.

The inclusion of aggregates also contributes to the floor’s structural integrity. By increasing the thickness and density of the epoxy layer, aggregates help to withstand heavy traffic and mechanical impacts, which is particularly beneficial in commercial and industrial settings. Moreover, they can improve the floor’s resistance to abrasion and chemical exposure, extending its lifespan and maintaining its appearance over time.

Different types of aggregates can be chosen based on the specific requirements of the space. For instance, in areas where cleanliness is paramount, such as hospitals or laboratories, a finer aggregate might be selected for easier maintenance. Conversely, in manufacturing facilities, a coarser aggregate might offer the enhanced durability needed to endure heavy machinery and equipment.

Importance of Additives and Pigments

Additives and pigments are crucial components in the creation of epoxy floors, serving to enhance both their performance and visual appeal. These elements are introduced into the epoxy resin to tailor the floor to specific functional requirements and aesthetic preferences. Understanding their role can help in making informed decisions when selecting the ideal epoxy flooring solution.

Additives are chemical compounds mixed with the epoxy resin to modify its properties. These could include UV stabilizers, which prevent the floor from yellowing or fading when exposed to sunlight, making them a great choice for areas with significant natural light exposure. Other additives might be used to improve the floor’s chemical resistance, ensuring that the surface remains intact and unblemished even when exposed to harsh substances. Additionally, anti-slip additives can be incorporated to enhance safety, particularly in wet or high-traffic areas.

On the other hand, pigments are used to add color and vibrancy to epoxy floors. They allow for a wide range of hues, from subtle earth tones to bold, vibrant colors, enabling the creation of unique and personalized spaces. Pigments can also be used to create specific patterns or effects, such as marbling or speckling, which can add a level of sophistication and distinction to any environment.

The use of pigments also extends to functionality; for example, different colors can be employed to designate specific zones within a facility, aiding in organization and safety. This functionality, combined with the aesthetic versatility offered by pigments, makes them an indispensable component of any epoxy flooring system.

Advantages of Epoxy Floor Composition

The composition of epoxy flooring offers a multitude of advantages that make it a popular choice for both residential and commercial spaces. Understanding these benefits can help you appreciate why many property owners prefer epoxy over other flooring options.

One significant advantage of epoxy floor composition is its durability. The chemical structure of epoxy creates a hard, resilient surface that can withstand heavy traffic, making it ideal for industrial and commercial environments. This durability means that epoxy floors maintain their integrity and appearance even under challenging conditions, such as in warehouses or garages.

Another benefit is its chemical resistance. Epoxy floors are highly resistant to a variety of chemicals, including oils, acids, and solvents, which makes them an excellent choice for laboratories, hospitals, and manufacturing plants where spills are common. This resistance not only protects the floor but also ensures a safer environment by preventing hazardous spills from causing damage.

In addition to its functional benefits, epoxy flooring is also prized for its versatility in design. With the inclusion of various pigments and additives, epoxy floors can be customized to fit any aesthetic preference, offering endless possibilities for color, pattern, and texture. Whether you’re aiming for a sleek, modern look or a more traditional style, epoxy can be tailored to meet your needs.

Lastly, epoxy floors are easy to maintain. Their seamless surface makes cleaning a breeze, and they do not require frequent polishings or treatments, unlike some other flooring options. This ease of maintenance translates to long-term cost savings, as the need for repairs or replacements is minimized.

Applications of Epoxy Flooring Materials

Epoxy flooring materials are incredibly versatile, finding applications in a wide range of settings due to their robust properties. Understanding these applications can guide you in choosing the right flooring solution for your specific needs.

One of the primary applications of epoxy flooring is in industrial environments. Factories, warehouses, and manufacturing plants benefit from epoxy’s durability and resistance to heavy machinery and high foot traffic. The seamless and easy-to-clean nature of epoxy also makes it ideal for these settings, where hygiene and safety are paramount.

In addition to industrial uses, epoxy flooring is frequently utilized in commercial settings, such as retail stores, showrooms, and hotels. Its aesthetic appeal and ability to be customized with various colors and patterns allow businesses to create attractive and welcoming environments that align with their brand image.

Moreover, epoxy floors are popular in residential spaces, particularly in garages, basements, and kitchens. Homeowners appreciate the material’s resistance to spills, stains, and abrasion, as well as its ability to enhance the overall look of the space. With epoxy, it’s possible to achieve a high-end finish that is both functional and beautiful.

Finally, the healthcare and education sectors also frequently use epoxy flooring. In hospitals, clinics, and schools, the seamless nature of epoxy floors prevents the accumulation of dirt and germs, ensuring a clean and sanitary environment. This makes them an ideal choice for areas where cleanliness is crucial.

Whether you are considering epoxy flooring for industrial, commercial, or residential use, its adaptability and resilience make it a smart choice for any setting. If you’re ready to explore how epoxy flooring can benefit your space, Call Us Today for a Free Quote and discover the possibilities with Americas Industrial Coatings.