When you step into your garage, you might not immediately think about what lies beneath your feet, but the material of your garage floor is crucial. Understanding what your garage floor is made of can significantly impact its durability, maintenance, and overall appearance. Homeowners often find themselves contemplating the right material that not only withstands the daily wear and tear but also enhances the aesthetic appeal of their space.

In this article, we will walk you through the various materials commonly used for garage floors, and highlight their unique benefits. Whether you’re considering revamping your existing floor or installing a new one, it’s crucial to make an informed decision tailored to your specific needs and preferences.

**Call Us Today for a Free Quote** to discover the best options for your garage floor at Americas Industrial Coatings! Our experts are ready to assist you in selecting the perfect flooring solution that combines functionality with style.

Common Garage Floor Materials Explained

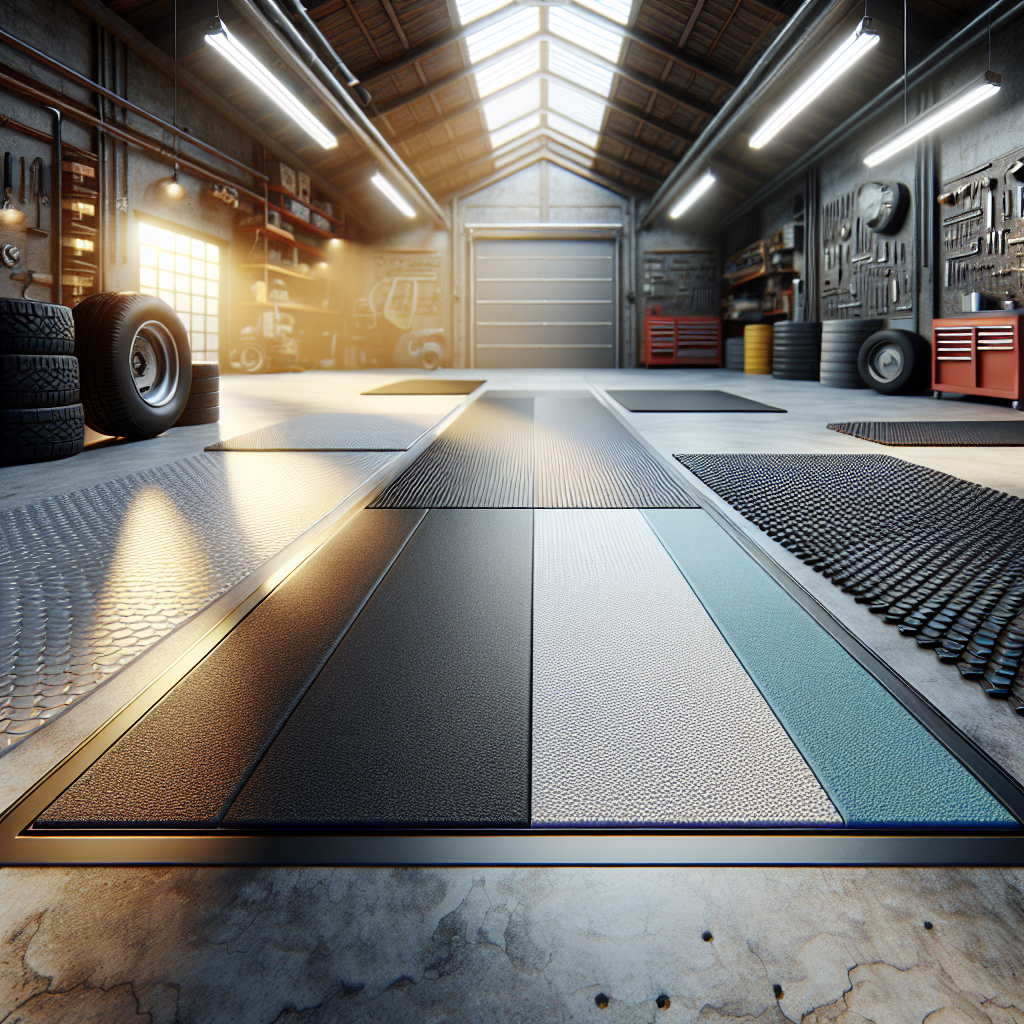

When exploring garage floor options, it’s essential to understand the variety of materials available and their distinct properties. Here, we break down some of the most common garage floor materials to help you make an informed choice:

- Concrete: The most prevalent material, concrete is favored for its durability and cost-effectiveness. It’s a strong surface capable of withstanding heavy loads and is highly customizable with finishes like polishing and staining.

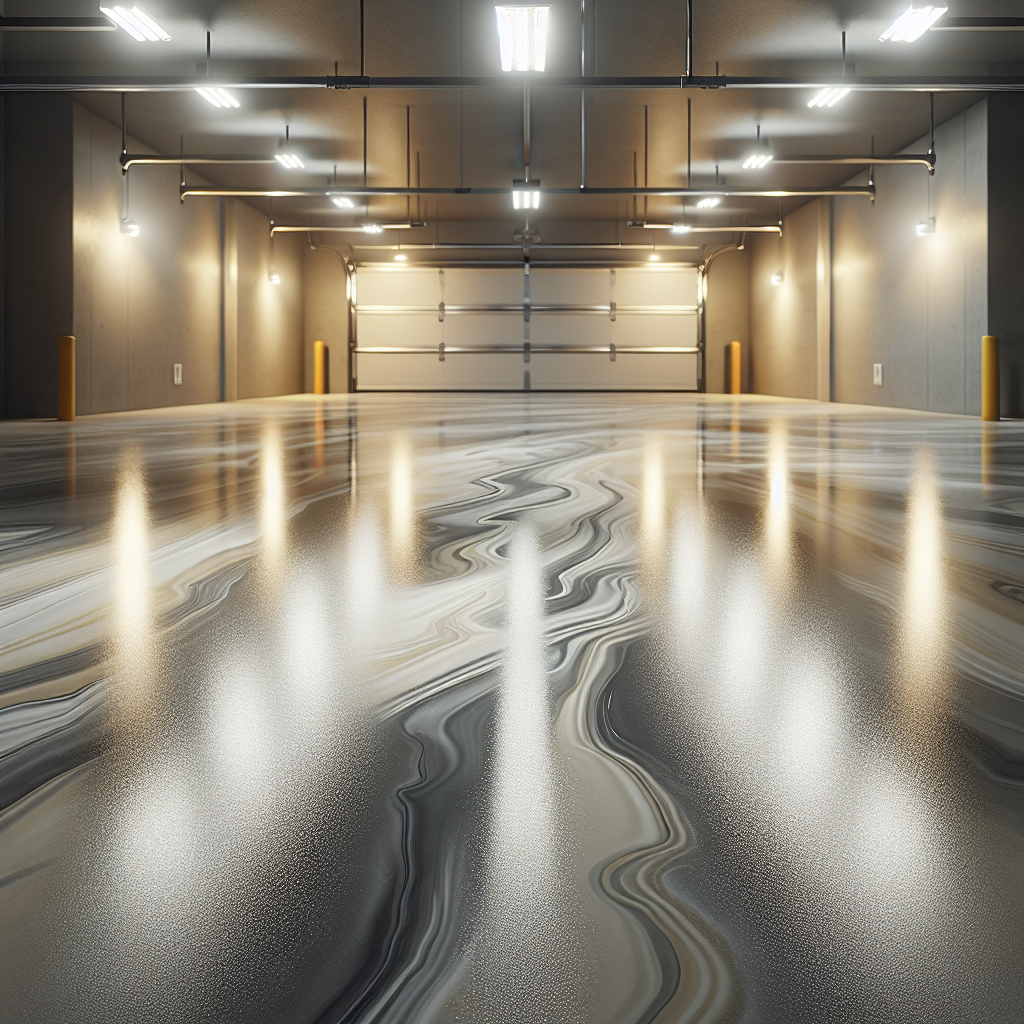

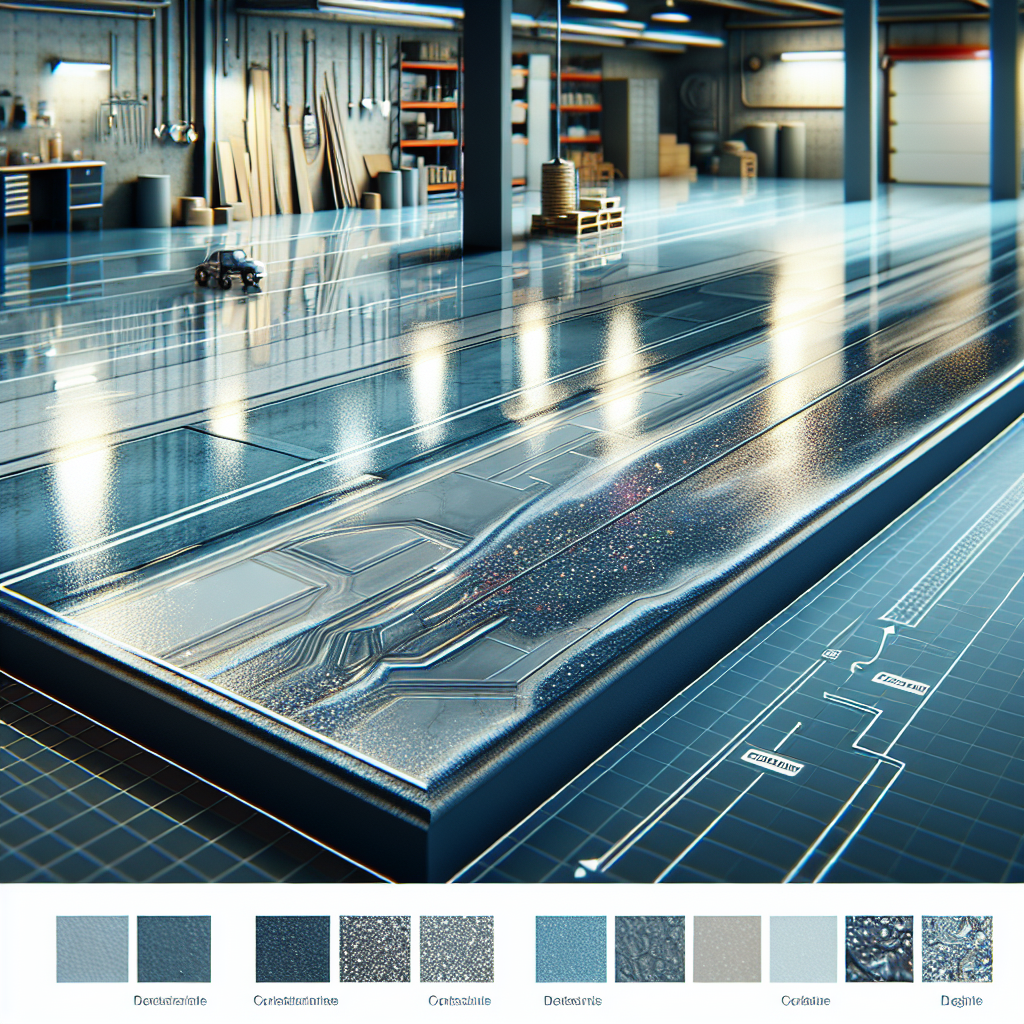

- Epoxy Coatings: Applied over concrete, epoxy offers a sleek, shiny finish. It is resistant to stains and chemicals, making it ideal for garages that experience spills or require easy cleaning. This option also comes in a variety of colors and patterns.

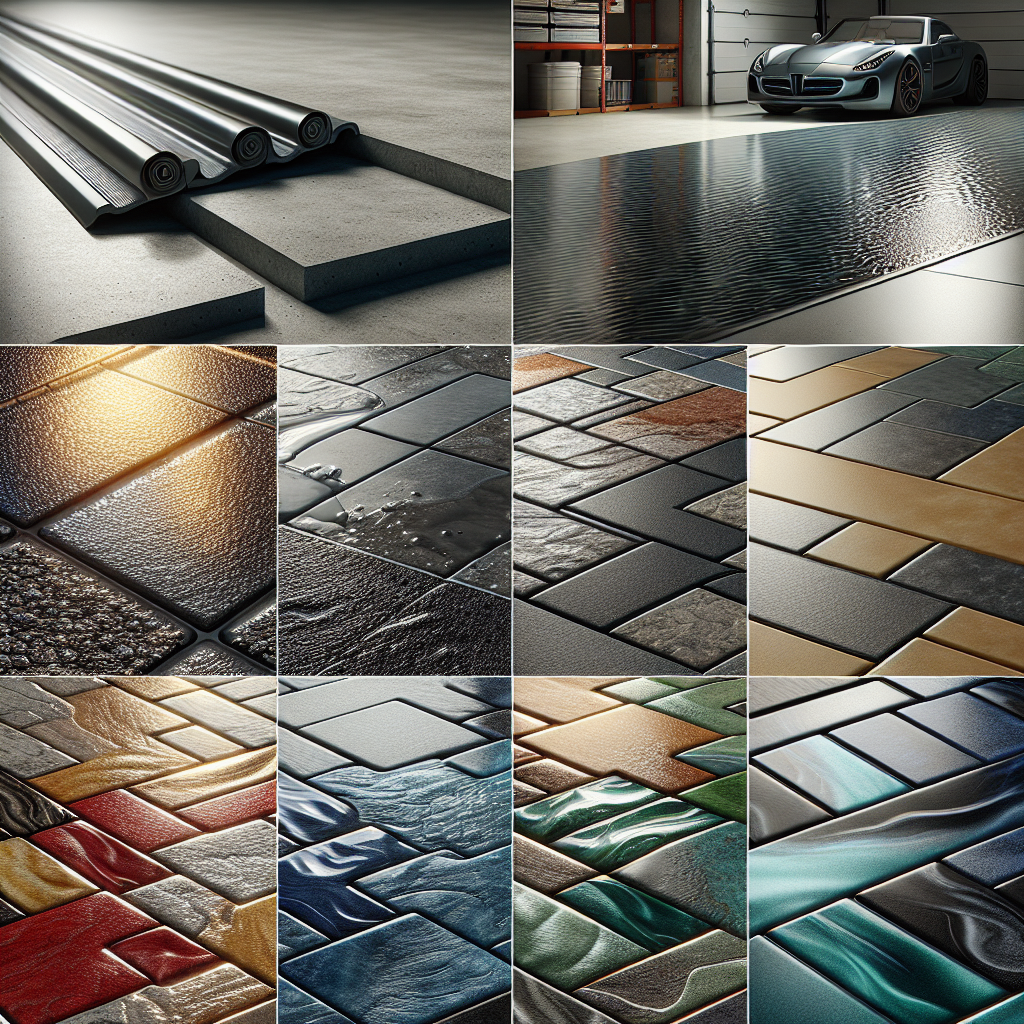

- Vinyl Tiles: These are popular for their ease of installation and variety of design options. Vinyl tiles are resilient and water-resistant, providing a softer feel underfoot compared to concrete.

- Rubber Flooring: Known for its comfort and shock absorption, rubber flooring is perfect for garages used as gyms or workshops. It’s easy to install and provides a non-slip surface.

- Interlocking Tiles: Made from materials like polypropylene, these tiles are easy to install and can be customized in color and design. They are durable and resistant to oils and chemicals, making them a practical choice for automotive enthusiasts.

Each material offers unique advantages, and the choice largely depends on the intended use of your garage, your budget, and your aesthetic preferences. By understanding these options, you can select a flooring material that not only meets your practical needs but also enhances the overall look of your garage space.

Benefits of Different Garage Floor Types

Choosing the right garage floor type can significantly impact the functionality and appearance of your garage. Each material offers distinct benefits that cater to different needs and preferences. Let’s delve into the advantages of various garage floor types:

- Concrete: Known for its longevity and strength, concrete is a low-maintenance choice that can withstand heavy machinery and vehicles. It provides a solid base that can be enhanced with sealants or coatings for added protection and aesthetic appeal.

- Epoxy Coatings: Epoxy not only enhances the visual appeal of concrete floors but also provides a protective layer that resists stains, chemicals, and abrasions. This makes it an excellent choice for those looking to maintain a clean and polished garage environment with minimal effort.

- Vinyl Tiles: Offering a cushioned feel underfoot, vinyl tiles are ideal for garages used for purposes beyond vehicle storage. They are easy to clean and come in a variety of styles, allowing you to personalize your space without compromising on durability.

- Rubber Flooring: This option is perfect for garages doubling as workout areas or playrooms. Rubber flooring provides exceptional shock absorption and is slip-resistant, ensuring a safe environment while reducing noise from dropped tools or equipment.

- Interlocking Tiles: These tiles offer versatility and ease of installation. They can be customized to fit any space and are resistant to oils and chemicals, making them a practical choice for auto enthusiasts who need a resilient and adaptable flooring solution.

Understanding the benefits of each garage floor type enables you to select the most suitable option that aligns with your garage’s usage and your personal style, ensuring both functionality and aesthetic satisfaction.

Comparing Durability and Maintenance

When selecting a garage floor material, it’s crucial to consider both durability and maintenance requirements. Different materials offer varying levels of resilience and upkeep demands, impacting long-term satisfaction and cost-effectiveness.

Concrete: Renowned for its robust nature, concrete floors can withstand substantial weight and impact, making them a popular choice for garages. However, they can be prone to cracking and may require periodic sealing to prevent moisture damage and staining. Regular sweeping and occasional pressure washing help maintain its appearance.

Epoxy Coatings: When applied to concrete floors, epoxy enhances durability by providing a protective layer that guards against chemicals, stains, and abrasions. Maintenance is relatively simple, involving regular sweeping and mopping to keep the glossy surface looking pristine. Epoxy’s resistance to wear and tear makes it a long-lasting option with minimal upkeep.

Vinyl Tiles: These tiles are durable enough to handle everyday garage activities but may not withstand extremely heavy loads as effectively as concrete or epoxy. They are easy to clean with standard household cleaners, and individual tiles can be replaced if damaged, simplifying maintenance.

Rubber Flooring: While not as hardwearing as concrete, rubber flooring’s durability is adequate for garages used for light-duty purposes. It is resistant to water and easy to clean with a damp mop, making it a low-maintenance option that also provides excellent shock absorption.

Interlocking Tiles: Known for their ease of installation and replacement, interlocking tiles boast moderate durability. They can handle typical garage use but may show wear over time if exposed to heavy machinery. Maintenance involves regular cleaning with mild detergents, and damaged tiles can be easily swapped out, maintaining the floor’s integrity.

By evaluating the durability and maintenance needs of each garage floor type, you can make an informed decision that balances convenience with longevity, ensuring your garage remains functional and attractive for years.

Choosing the Right Garage Floor Material

Selecting the right garage floor material involves evaluating several key factors, each contributing to the overall functionality and aesthetic appeal of your space. Begin by assessing the primary use of your garage. If it serves as a workshop or a storage area for heavy equipment, you might prioritize materials known for their **strength** and **durability**, such as concrete or epoxy coatings.

Consider the climate and environmental conditions in your area. In regions prone to high humidity or frequent rainfall, materials that offer **moisture resistance** and **anti-slip properties** are beneficial. Epoxy coatings and rubber flooring are excellent choices for their ability to withstand moisture without compromising safety.

Another crucial aspect is the ease of maintenance. If you prefer minimal upkeep, look for materials that are easy to clean and maintain, like vinyl tiles or interlocking tiles. These options allow for straightforward cleaning procedures and often permit easy replacement of individual sections if damage occurs.

Budget is also a significant factor. Concrete floors generally offer a cost-effective solution with their long lifespan and minimal initial investment. However, if you’re willing to spend more upfront for enhanced aesthetics and protection, epoxy coatings or decorative tiles can add a touch of elegance.

Finally, reflect on the aesthetic quality you desire. For a stylish and modern garage, consider materials that offer a wide range of colors and finishes. Epoxy coatings, in particular, can be customized to match your personal style, creating a visually appealing environment.

By weighing these considerations, you can make an informed choice that aligns with your functional needs, budget, and design preferences, ultimately enhancing the utility and visual appeal of your garage space.

Conclusion on Garage Floors

In conclusion, understanding what your garage floor is made of plays a vital role in maximizing the functionality and longevity of your space. Whether you opt for the durability of concrete, the aesthetic appeal of epoxy coatings, or the practicality of rubber tiles, each material offers unique benefits tailored to diverse needs and preferences. By considering factors such as usage, climate, maintenance, budget, and style, homeowners can make informed decisions that enhance both the utility and visual appeal of their garages.

The right flooring can transform your garage from a simple storage area into a functional and attractive extension of your home. As you embark on this journey of selecting the perfect garage floor, remember that professional guidance can make a significant difference. At Americas Industrial Coatings, we offer expert advice and services to help you make the best choice for your needs. Call Us Today for a Free Quote and discover how we can assist in creating a garage floor that meets your expectations and enhances your home.