When it comes to flooring solutions, epoxy floor coating layers have become increasingly popular due to their durability, aesthetic appeal, and ease of maintenance. This innovative flooring system consists of multiple layers, each serving a unique purpose to enhance the overall performance and longevity of your floors. Understanding these layers is essential for anyone considering an epoxy flooring installation, whether for a residential garage or a commercial space.

Typically, the epoxy flooring process begins with a preparation phase where the existing floor is cleaned and repaired as necessary. Following this, the first layer is applied, which acts as a base coat. Subsequent layers, including a colored or decorative layer and a top coat, are then added to create a robust and visually appealing surface. Each layer interacts with the others, providing benefits such as chemical resistance, slip resistance, and aesthetic versatility.

For homeowners and business owners alike, understanding these epoxy floor coating layers is crucial not only for making informed decisions but also for ensuring that the flooring system meets specific needs. This comprehensive guide will delve deeper into each layer’s function and the advantages they offer.

If you’re considering a new flooring system, Call Us Today for a Free Quote and let our experts guide you through the process!

Types of Epoxy Floor Coating Layers Explained

Understanding the different types of epoxy floor coating layers is essential for selecting the right flooring solution for your needs. Each layer serves a specific purpose and contributes to the overall functionality and aesthetics of the floor.

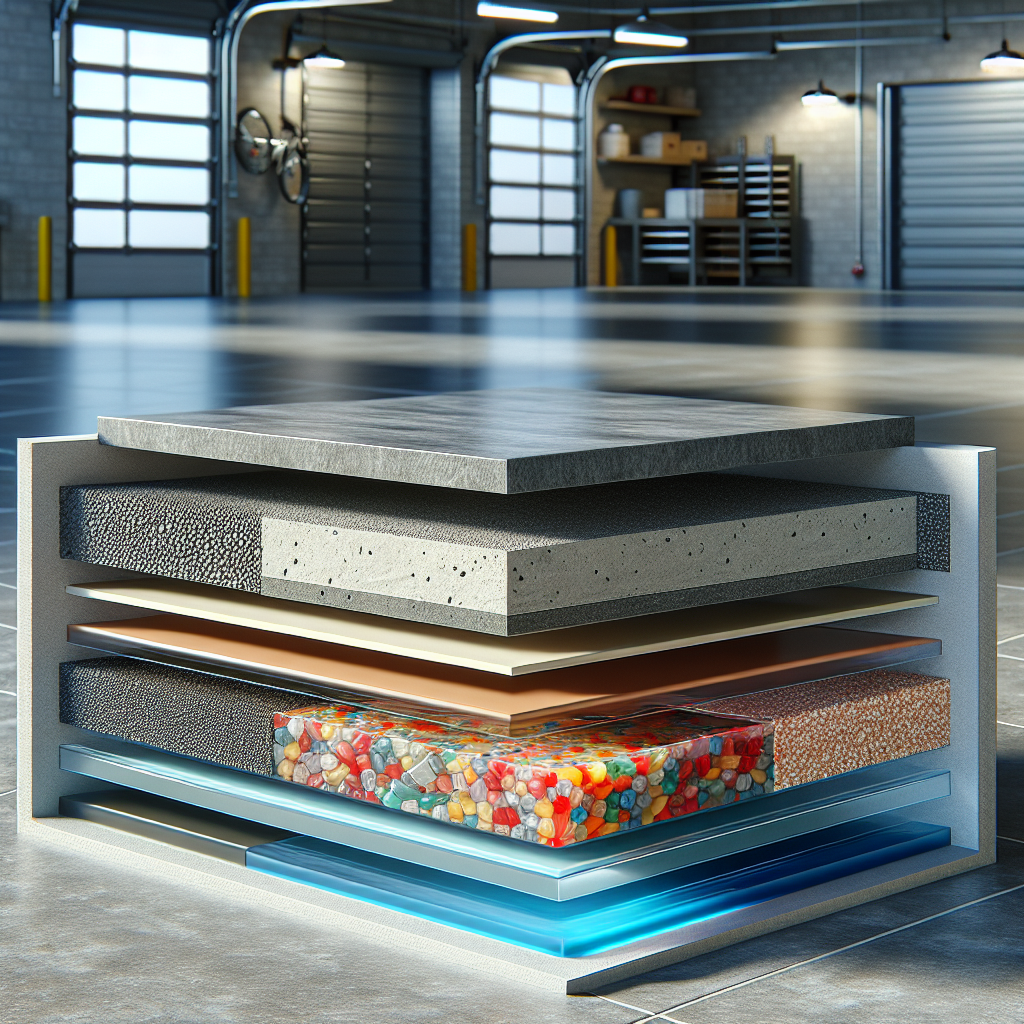

- Primer Layer: This initial layer is crucial for adhesion. It helps the subsequent layers bond properly to the substrate, ensuring a strong foundation. Primers are typically formulated to penetrate the surface, creating a durable base for the entire flooring system.

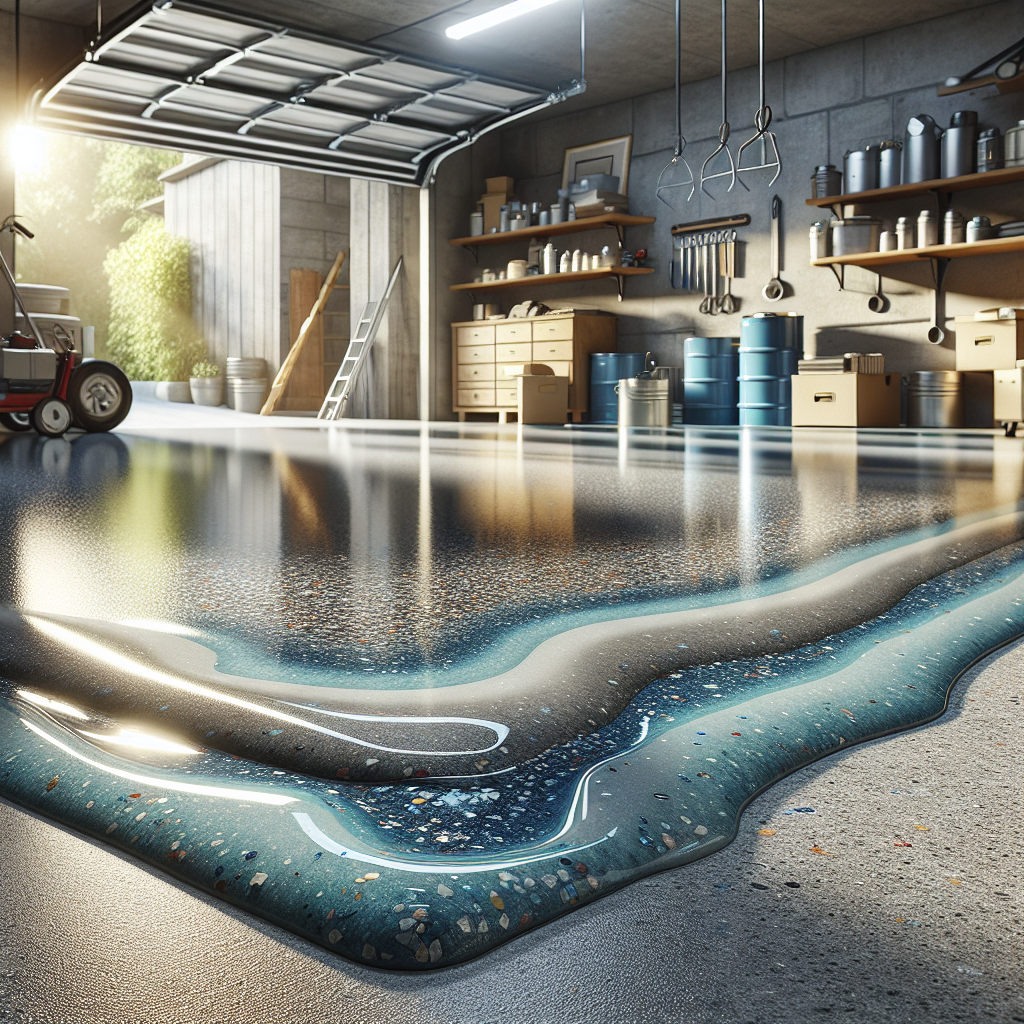

- Base Coat: The base coat is where the main color or design of your floor begins to take shape. This layer can be customized with various colors and additives, such as decorative chips, to enhance the visual appeal. It also provides resistance to wear and tear, making it ideal for high-traffic areas.

- Decorative Layer: For those looking to add a unique touch, the decorative layer can incorporate various textures, patterns, or even metallic finishes. This layer not only enhances the aesthetic quality but can also improve slip resistance, making it a practical choice for both residential and commercial spaces.

- Top Coat: The final layer in the epoxy flooring system, the top coat provides a protective barrier against chemicals, stains, and abrasions. Depending on the formulation, it can also offer UV resistance and enhance the durability of the flooring, ensuring it maintains its appearance over time.

Choosing the right combination of these epoxy floor coating layers allows you to tailor your flooring to meet specific requirements, whether for safety, aesthetics, or functionality. By understanding these components, you can make informed decisions that will benefit your space for years to come.

Benefits of Multiple Epoxy Coating Layers

Utilizing multiple epoxy coating layers in your flooring system offers numerous advantages that enhance both the performance and longevity of your floors. Here are some key benefits to consider:

- Enhanced Durability: Each layer adds an additional level of protection against wear and tear. This multi-layered approach significantly extends the lifespan of your flooring, making it suitable for high-traffic areas.

- Improved Adhesion: When you apply multiple layers, you create a stronger bond between the flooring and the substrate. This reduces the chances of peeling or delamination, ensuring that your floor remains intact over time.

- Customizable Aesthetics: Multiple layers allow for greater customization options. You can choose different colors, patterns, and textures for each layer, leading to a unique and visually appealing floor that meets your design preferences.

- Increased Chemical Resistance: By implementing a layered approach, each layer can be formulated to resist specific chemicals or substances. This makes epoxy coatings ideal for environments such as warehouses, laboratories, and garages where spills are common.

- Enhanced Safety: Additional layers can improve slip resistance, particularly in areas prone to moisture or spills. This added safety feature is crucial for both residential and commercial spaces.

- Ease of Maintenance: Multi-layered epoxy floors are generally easier to clean and maintain. The top layers can be designed to resist stains and dirt, allowing for a clean appearance with minimal effort.

Incorporating multiple epoxy coating layers not only elevates the performance of your flooring system but also ensures that it aligns with your specific needs and aesthetic desires. By investing in a comprehensive epoxy flooring solution, you can enjoy a beautiful and durable floor for years to come.

Step by Step Application Process for Epoxy Layers

The application of epoxy floor coating layers involves a meticulous process that ensures optimal adhesion and durability. Below is a step-by-step guide to help you understand how professionals achieve a flawless finish:

- Surface Preparation: The first and most crucial step is preparing the surface. This involves cleaning the area thoroughly to remove any dirt, grease, or old coatings. Often, this may include grinding or shot blasting the surface to ensure it is rough enough for the epoxy to adhere effectively.

- Repairing Damage: Any cracks or imperfections in the concrete should be filled and repaired. This ensures a smooth and even surface for the epoxy application.

- Primer Application: A primer coat is applied to enhance adhesion. This layer helps the subsequent epoxy coatings bond better with the substrate. Depending on the specific epoxy system used, the primer may need to cure for a certain period.

- First Epoxy Layer: The first epoxy layer is mixed according to the manufacturer’s specifications and applied evenly across the surface. This layer typically serves as the base and is critical for overall performance. It is essential to ensure that this layer is applied at the correct thickness.

- Curing Time: Allow the first epoxy layer to cure completely. Curing times can vary based on factors like temperature and humidity but generally range from several hours to a day.

- Second Epoxy Layer: After the first layer has cured, a second coat is applied. This layer can be tinted or blended with decorative flakes to enhance aesthetics. Again, proper application techniques are vital to avoid imperfections.

- Final Curing: Once all layers have been applied, allow the entire system to cure. It is critical to follow the manufacturer’s recommendations regarding curing times before the surface is subjected to foot traffic or heavy loads.

By following this step-by-step application process, you can ensure that your epoxy flooring achieves its maximum potential in terms of durability, aesthetics, and overall performance.

Maintenance Tips for Epoxy Floor Coatings

Maintaining epoxy floor coatings is essential to ensure their longevity and aesthetic appeal. Proper care can prevent damage and keep your floors looking pristine for years. Here are some effective maintenance tips:

- Regular Cleaning: Sweep or vacuum the floor regularly to remove dirt and debris. Use a damp mop with a gentle cleaner to wipe down the surface. Avoid harsh chemicals that can break down the epoxy over time.

- Spot Cleaning: For spills or stains, clean them immediately to prevent them from setting in. Use a soft cloth or sponge with a mild detergent to gently scrub the area.

- Avoid Abrasive Tools: When cleaning your epoxy floors, avoid using abrasive scrubbers or brushes that can scratch the surface. Opt for soft cloths or mops to maintain the floor’s integrity.

- Use Floor Mats: Place mats at entry points to minimize dirt and moisture being tracked onto the epoxy surface. This practice can help reduce wear and tear significantly.

- Prevent Heavy Impacts: While epoxy is durable, it’s wise to avoid dropping heavy objects on the floor, as this could cause chipping or cracking. Consider using protective pads under heavy furniture.

- Recoat as Needed: Depending on the level of foot traffic and wear, you may need to apply a new topcoat every few years. This can help restore shine and provide an additional layer of protection.

By following these maintenance tips, you can ensure that your epoxy floor coatings remain in excellent condition, enhancing both the functionality and appearance of your space.

Choosing the Right Epoxy Coating Layers for Your Needs

Selecting the appropriate epoxy coating layers for your specific needs is crucial for achieving optimal performance and appearance. With various options available, understanding the factors that influence your choice can make a significant difference in the longevity and durability of your floors. Here are some key considerations:

- Type of Environment: Assess whether the space is residential, commercial, or industrial. Different environments may require distinct types of epoxy, such as high-gloss finishes for showrooms or slip-resistant options for garages and warehouses.

- Floor Traffic: Consider the volume and type of foot or vehicle traffic the floor will endure. High-traffic areas may benefit from thicker, more durable layers designed to withstand wear and tear.

- Moisture Levels: If the area is prone to moisture, such as basements or outdoor spaces, choose a moisture-resistant epoxy that can prevent peeling and bubbling.

- Aesthetic Preferences: Epoxy coatings come in various colors and finishes. Determine the desired look for your space, whether it’s a sleek, modern finish or a more textured appearance.

- Budget: Establish a budget for your project. While investing in higher-quality epoxy may incur initial costs, it can save money in the long run by reducing maintenance and replacement needs.

To make an informed decision, it may be beneficial to consult with professionals who specialize in epoxy flooring. Call Us Today for a Free Quote and let our experts guide you in selecting the right epoxy coating layers tailored to your unique requirements.