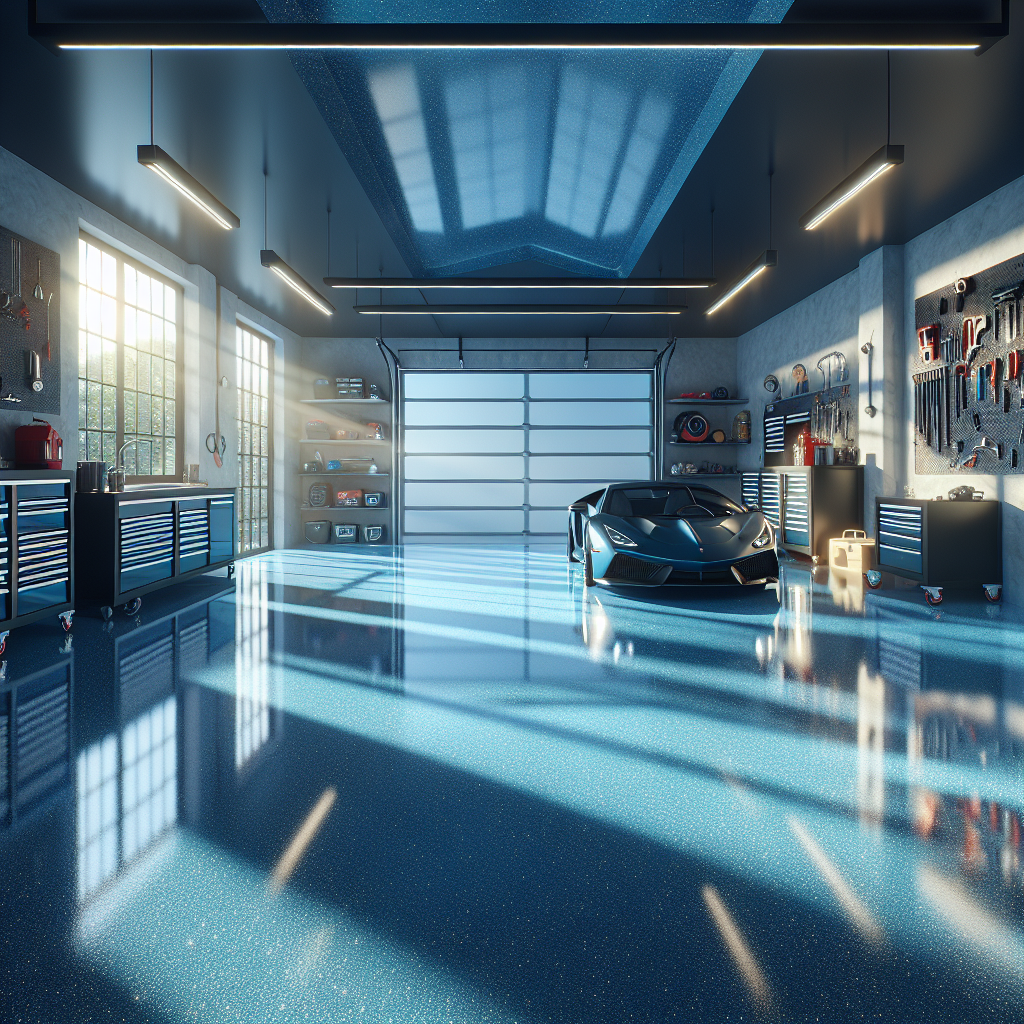

When it comes to enhancing the functionality and aesthetics of your garage, understanding epoxy garage floor coatings is crucial. These coatings are made from a blend of epoxy resins and hardeners, creating a durable surface that can withstand heavy traffic and resist various chemicals.

The application of epoxy not only improves the floor’s durability but also offers a sleek, shiny finish that can transform your garage into a more appealing space. Moreover, epoxy coatings come in a variety of styles and colors, allowing you to customize the look of your garage to suit your personal taste.

Some of the key benefits of choosing epoxy for your garage floor include:

- Durability: Epoxy coatings are known for their strength and resistance to wear and tear, making them ideal for high-traffic areas.

- Easy Maintenance: The smooth surface of epoxy makes it easy to clean, requiring just a simple wash to keep it looking pristine.

- Protection: Epoxy provides a barrier against spills and stains, protecting your concrete from damage.

Additionally, the right top coat can enhance these benefits significantly, ensuring your epoxy garage floor not only looks great but also lasts for years to come. Call Us Today for a Free Quote and let us help you select the best top coat for your epoxy garage floor that will meet your specific needs.

Importance of Choosing the Right Top Coat

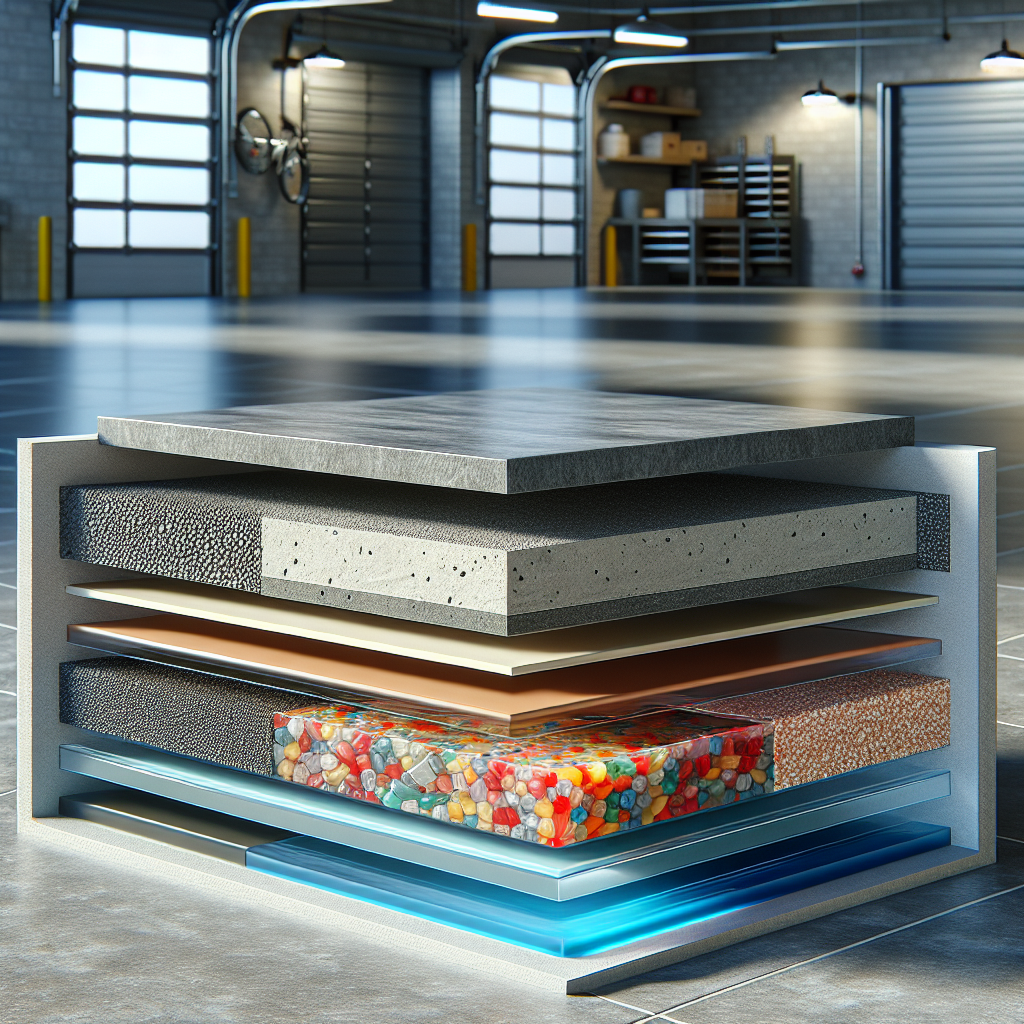

Selecting the right top coat for your epoxy garage floor is essential for maximizing its performance and longevity. The top coat serves as a protective layer that enhances the overall durability of the epoxy while also improving its aesthetic appeal. Here are several reasons why choosing the right top coat is vital:

- Enhanced Protection: A quality top coat provides an additional barrier against scratches, stains, and chemical spills, which can otherwise penetrate the epoxy and cause damage to the underlying concrete.

- UV Resistance: Some top coats are specifically designed to resist fading from ultraviolet (UV) rays. This is particularly important if your garage has windows or receives a lot of sunlight, as prolonged exposure can lead to discoloration and wear.

- Slip Resistance: The right top coat can also improve safety by offering a slip-resistant surface. This is especially beneficial in garages that may become wet or oily, reducing the risk of accidents.

- Longevity: A high-quality top coat can significantly extend the life of your epoxy flooring by preventing wear and tear caused by daily use and environmental factors.

Investing in the best top coat for your epoxy garage floor not only protects your investment but also ensures that your garage remains an attractive and functional space for years to come.

Top Features to Look for in Top Coats

When selecting a top coat for your epoxy garage floor, it is crucial to consider specific features that can enhance the performance and appearance of your flooring. Here are some of the top features to look for:

- Durability: Opt for a top coat that can withstand heavy foot traffic, vehicle weight, and potential impacts. Look for products made from high-quality materials that promise long-lasting performance.

- Chemical Resistance: A top coat with excellent resistance to harsh chemicals, oils, and solvents is essential for maintaining the integrity of your epoxy floor. This feature is particularly important for garages where automotive work is conducted.

- Ease of Application: Choose a top coat that is easy to apply and does not require extensive preparation. Some products come with user-friendly instructions that make the application process straightforward.

- Finish Options: Consider the finish of the top coat, whether you prefer a glossy, satin, or matte look. The finish can significantly affect the overall aesthetic of your garage.

- Drying Time: Look for top coats that offer a quick drying time, allowing you to return to using your garage sooner. Fast-drying products can minimize downtime during installation.

By focusing on these key features, you can ensure that you select a top coat that complements your epoxy garage floor and meets your specific needs.

Our Recommended Top Coats for Epoxy Floors

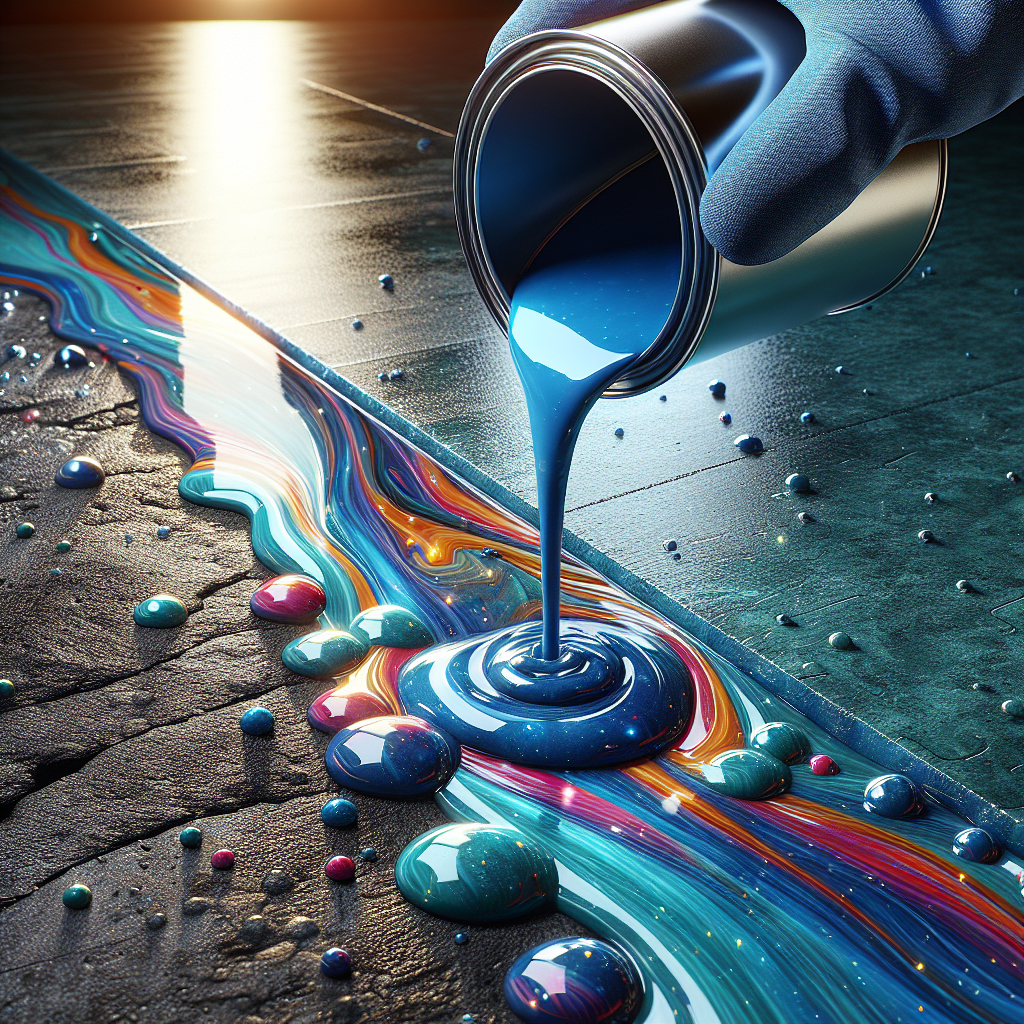

Choosing the right top coat for your epoxy floor is essential for achieving optimal durability and aesthetics. Here are some of our recommended top coats that stand out in terms of performance and reliability:

- Polyaspartic Coatings: Known for their rapid curing time and excellent UV stability, polyaspartic top coats provide a durable and glossy finish. They are perfect for high-traffic areas and can be applied in various weather conditions.

- Urethane Top Coats: These coatings offer exceptional chemical resistance and are ideal for garages that may experience spills from automotive fluids. Urethane top coats provide a flexible layer that can withstand temperature fluctuations without cracking.

- Epoxy Clear Coats: For those who prefer a seamless look, epoxy clear coats enhance the color and depth of the underlying epoxy while providing a robust protective barrier. They are also resistant to abrasions, making them a favorite among homeowners.

- Water-Based Acrylic Coatings: If you’re looking for an eco-friendly option, water-based acrylic coatings are a great choice. They are easy to apply and quick to dry, offering a semi-gloss finish that adds a touch of elegance to your garage.

Each of these top coats comes with unique benefits, ensuring that you can find the perfect fit for your epoxy garage floor.

Application Tips for Top Coats

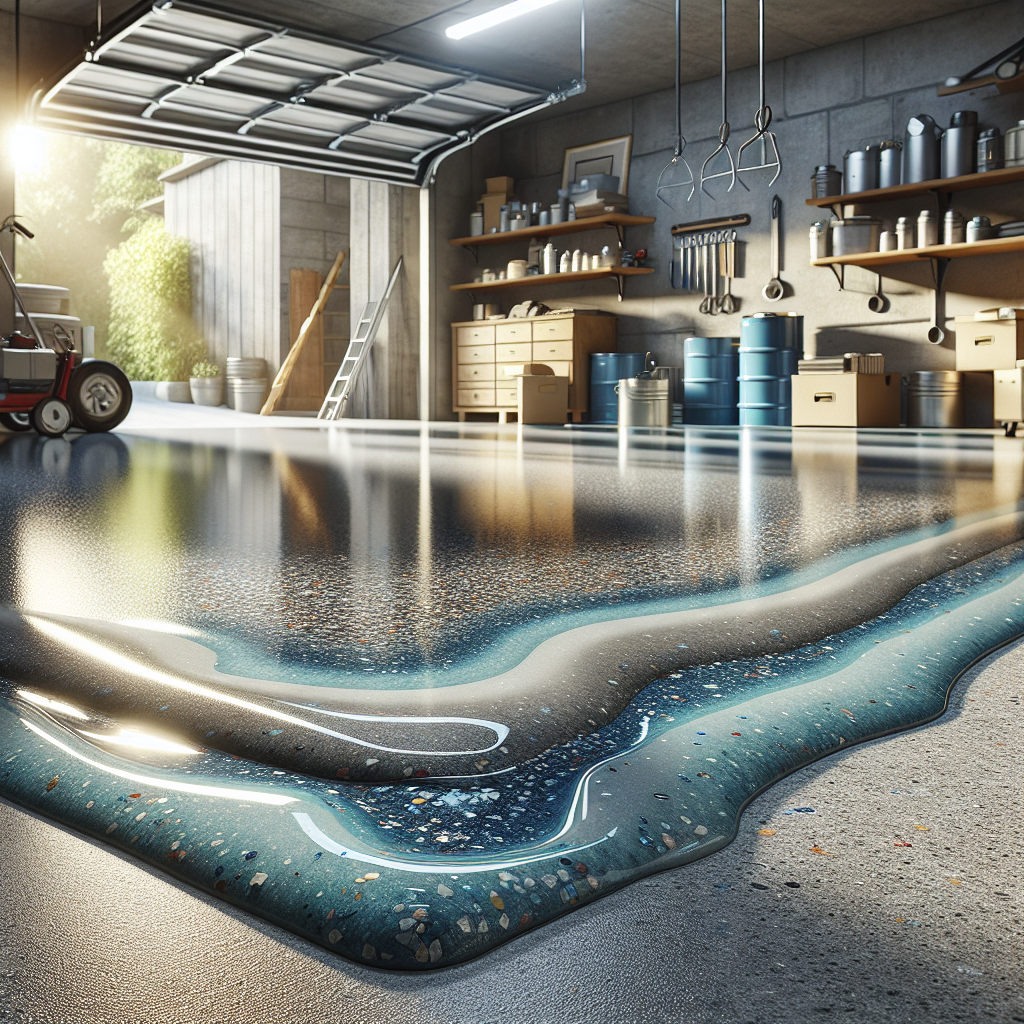

Applying a top coat to your epoxy floor can greatly enhance its appearance and longevity. Here are some essential application tips to ensure the best results:

- Surface Preparation: Before applying any top coat, ensure that the surface is clean, dry, and free from any debris or contaminants. A well-prepared surface allows for better adhesion and a smoother finish.

- Temperature and Humidity: Check the weather conditions before application. Ideally, the temperature should be between 60°F and 80°F, and humidity levels should be low to ensure proper curing. High humidity can lead to blushing or improper curing of the top coat.

- Mixing: When using two-component top coats, mix them thoroughly according to the manufacturer’s instructions. Make sure to use a clean mixing container to avoid contamination and ensure an even application.

- Application Technique: Use a high-quality roller or sprayer designed for the specific type of top coat you are applying. Apply the coat evenly and avoid overworking the product, as this can lead to bubbles or an uneven finish.

- Multiple Coats: For enhanced durability, consider applying multiple thin coats instead of one thick layer. Allow adequate drying time between coats as recommended by the manufacturer.

Following these tips will help you achieve a professional-looking finish that enhances both the durability and aesthetics of your epoxy floor.

Maintaining Your Epoxy Garage Floor Top Coat

Once you have applied the top coat to your epoxy garage floor, proper maintenance is crucial to ensure its longevity and appearance. Here are some effective strategies for maintaining your epoxy floor top coat:

- Regular Cleaning: Keep your floor clean by sweeping or vacuuming regularly to remove dirt, dust, and debris. For more thorough cleaning, use a mild detergent mixed with water and a soft mop. Avoid harsh chemicals that could damage the top coat.

- Immediate Stain Removal: Address spills or stains promptly to prevent them from penetrating the surface. Use a soft cloth or sponge and a gentle cleaner to wipe away any contaminants.

- Avoid Heavy Loads: While epoxy floors are durable, avoid placing excessively heavy objects on them for extended periods to prevent any potential damage to the top coat.

- Periodic Inspections: Regularly inspect your floor for any signs of wear or damage. If you notice any issues, address them immediately to prevent further deterioration.

- Reapplication: Depending on the traffic and use of your garage, consider reapplying the top coat every few years to maintain its protective qualities and appearance.

By following these maintenance tips, you can keep your epoxy garage floor looking great and performing well for years to come. Call Us Today for a Free Quote to explore how we can assist you with your epoxy flooring needs!