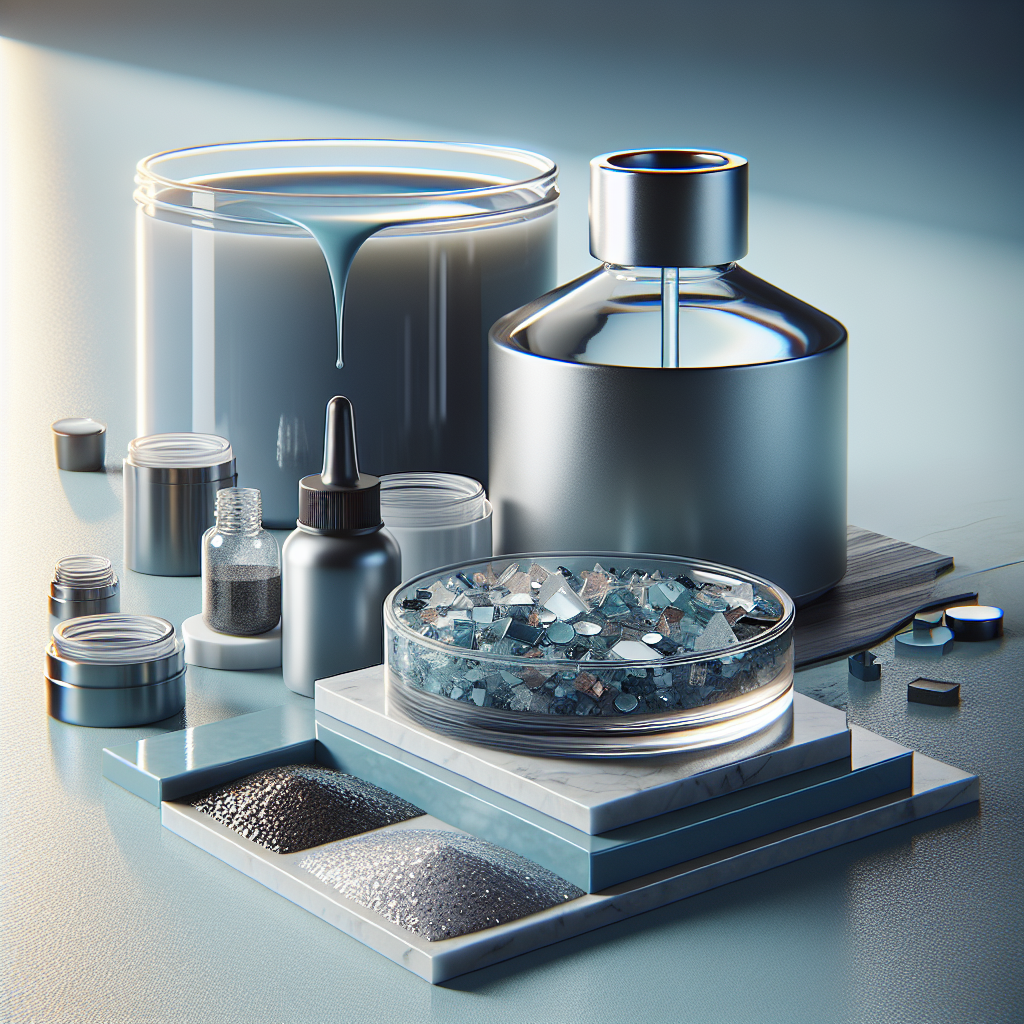

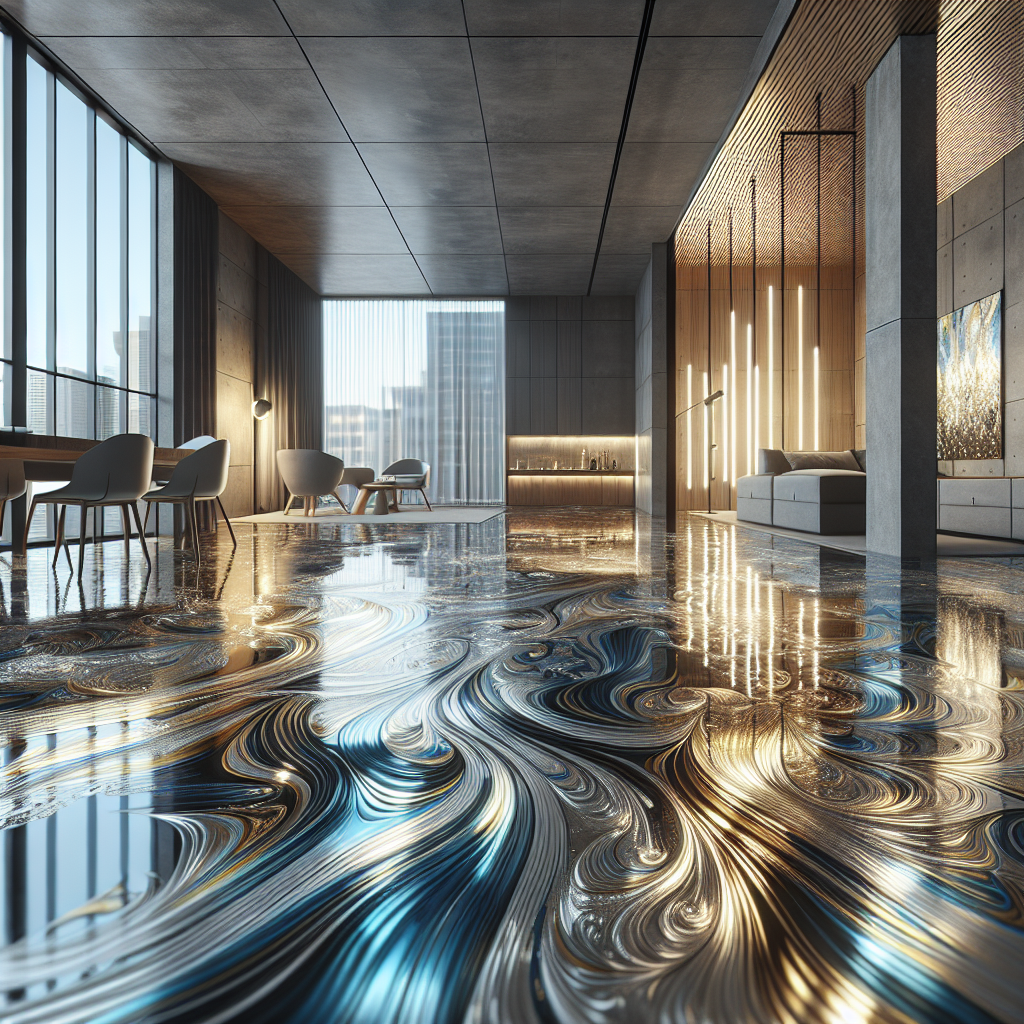

Metallic epoxy flooring is an innovative and visually stunning option for both residential and commercial spaces. This type of flooring is created by mixing a special epoxy resin with metallic pigments, resulting in a glossy, three-dimensional appearance that can enhance any environment. The unique reflective qualities of metallic epoxy can create a sense of depth and space, making it ideal for areas where aesthetics are as important as functionality.

One of the primary advantages of metallic epoxy flooring lies in its durability. Once cured, it forms a hard, resilient surface that is resistant to scratches, stains, and chemical spills, making it particularly suitable for high-traffic areas such as garages, warehouses, and retail spaces. Additionally, the seamless nature of epoxy flooring means there are no joints or seams for dirt and bacteria to accumulate, promoting a more sanitary environment.

However, it is essential to understand that the installation process requires experience and expertise. Improper application can lead to issues such as bubbles or uneven surfaces. Therefore, it’s advisable to seek professional assistance for a flawless finish. If you’re considering this flooring option, call us today for a free quote and let Americas Industrial Coatings guide you through the process of transforming your space with expert metallic epoxy flooring installation.

Advantages of Using Metallic Epoxy Flooring

Metallic epoxy flooring offers a multitude of advantages that make it an appealing choice for various applications. One of the most significant benefits is its visual appeal. The unique blend of colors and effects creates a stunning, customized look that can complement any design aesthetic, from modern to industrial. This flooring can transform ordinary spaces into extraordinary environments, attracting attention and enhancing the overall ambiance.

Another advantage is its durability. Unlike traditional flooring options, metallic epoxy is resistant to wear and tear, making it ideal for high-traffic areas. It can withstand heavy loads, impacts, and abrasions, ensuring that it maintains its appearance and integrity over time. Additionally, this flooring type is resistant to moisture and stains, making it suitable for areas prone to spills or humidity, such as kitchens and bathrooms.

Maintenance is also a breeze with metallic epoxy flooring. Its seamless surface prevents the accumulation of dirt, dust, and allergens, making it easier to clean compared to other flooring options. A simple mopping or sweeping is typically sufficient to keep it looking pristine. Furthermore, metallic epoxy is eco-friendly, as it can be applied over existing floors, reducing the need for demolition and minimizing waste.

In summary, the advantages of using metallic epoxy flooring include its stunning aesthetics, durability, easy maintenance, and environmental friendliness, making it a perfect choice for both residential and commercial spaces.

Disadvantages of Metallic Epoxy Flooring

While metallic epoxy flooring presents numerous benefits, it is essential to consider its disadvantages as well. One of the primary concerns is the installation process. Achieving a flawless finish requires skilled professionals with experience in applying metallic epoxy. Improper installation can lead to issues like bubbling, peeling, or an uneven surface, which can be costly to rectify.

Another drawback is the cost. Compared to traditional flooring materials, metallic epoxy can be more expensive due to the labor-intensive application process and the quality of materials used. For budget-conscious consumers, this may pose a challenge, especially when considering larger spaces.

Additionally, while metallic epoxy is durable, it is not indestructible. Heavy items dropped on the surface can still cause chipping or cracking. Moreover, exposure to harsh chemicals or extreme temperatures can affect its integrity, making it crucial to choose appropriate cleaning products and maintenance practices.

Lastly, the slipperiness of metallic epoxy flooring can be a concern, particularly in areas prone to moisture. While anti-slip additives can be incorporated during installation, this is an additional step that must be considered to ensure safety.

In conclusion, the disadvantages of metallic epoxy flooring include the complexities of the installation process, higher cost, potential for damage, and issues with slipperiness. Weighing these factors against the advantages is essential for making an informed flooring decision.

Ideal Applications for Metallic Epoxy Flooring

Metallic epoxy flooring is renowned for its stunning aesthetics and durability, making it a popular choice for various environments. Its visual appeal and strength allow it to be utilized in both residential and commercial spaces.

One of the ideal applications for metallic epoxy flooring is in retail spaces. The unique designs and vibrant colors can create an inviting atmosphere that attracts customers while providing a seamless, easy-to-clean surface. Many retailers use it to enhance their brand image with customized designs that reflect their identity.

Similarly, showrooms benefit significantly from the installation of metallic epoxy flooring. The glossy finish accentuates products on display, making them stand out. Additionally, the durability of this flooring type ensures it can withstand heavy foot traffic while maintaining its aesthetic appeal.

In industrial settings, metallic epoxy flooring is also an excellent choice. Its resistance to chemicals and heavy loads makes it suitable for factories and warehouses, where spills and wear are common challenges. The easy maintenance of metallic epoxy means that cleaning and upkeep are manageable, allowing for safer work environments.

Lastly, residential applications are increasingly popular. Homeowners are using metallic epoxy flooring in basements, garages, and living spaces to achieve a modern look that is both functional and stylish. The ability to customize colors and patterns allows homeowners to express their personal style while enjoying a durable flooring option.

Overall, metallic epoxy flooring is versatile and suitable for a range of applications, from retail stores and showrooms to industrial spaces and residential homes.

Maintenance Tips for Metallic Epoxy Flooring

Maintaining metallic epoxy flooring is essential to preserve its stunning appearance and prolong its lifespan. While this type of flooring is durable and resistant to wear, implementing a few simple maintenance tips can ensure it remains in top condition.

First and foremost, regular cleaning is crucial. It is recommended to sweep or vacuum the floor at least once a week to remove dust and debris. For deeper cleaning, use a damp mop with a mild, pH-neutral cleaner. Avoid harsh chemicals or abrasive cleaners, as they can dull the finish and damage the epoxy.

Next, immediately address any spills. Metallic epoxy floors are resistant to stains, but it is still wise to clean up spills promptly to prevent any potential issues. Use a soft cloth or mop to wipe away liquids before they have a chance to settle.

To maintain the floor’s shine, consider applying a protective sealer every few years. This layer can help prevent scratches and maintain the glossy finish. When applying a sealer, ensure the floor is thoroughly cleaned and dried to achieve the best results.

Additionally, placing doormats at entry points can significantly reduce the amount of dirt and debris brought onto the floor. This simple step can minimize wear and tear, keeping your metallic epoxy flooring looking newer for longer.

Lastly, inspect the flooring regularly for any signs of damage or wear. Early detection of issues can prevent more significant problems down the line, ensuring your investment remains protected.

Conclusion on Metallic Epoxy Flooring Pros and Cons

In summary, metallic epoxy flooring offers a unique blend of aesthetic appeal and durability, making it an attractive option for various spaces. The pros include its stunning visual effects, resistance to stains and scratches, and ease of maintenance, which together create a floor that not only enhances the beauty of your environment but also stands up to everyday wear and tear.

However, it is essential to consider the cons as well. The initial installation cost can be higher than traditional flooring options, and the application process requires skilled professionals to ensure a flawless finish. Additionally, while metallic epoxy is durable, it can still be susceptible to damage from heavy impact, which may require prompt repairs.

Ultimately, deciding on metallic epoxy flooring involves weighing these pros and cons against your specific needs and budget. For those seeking a long-lasting and visually striking solution, the benefits often outweigh the drawbacks.

If you are considering installing metallic epoxy flooring in your space, Call Us Today for a Free Quote to discuss your options and get started on transforming your floor!