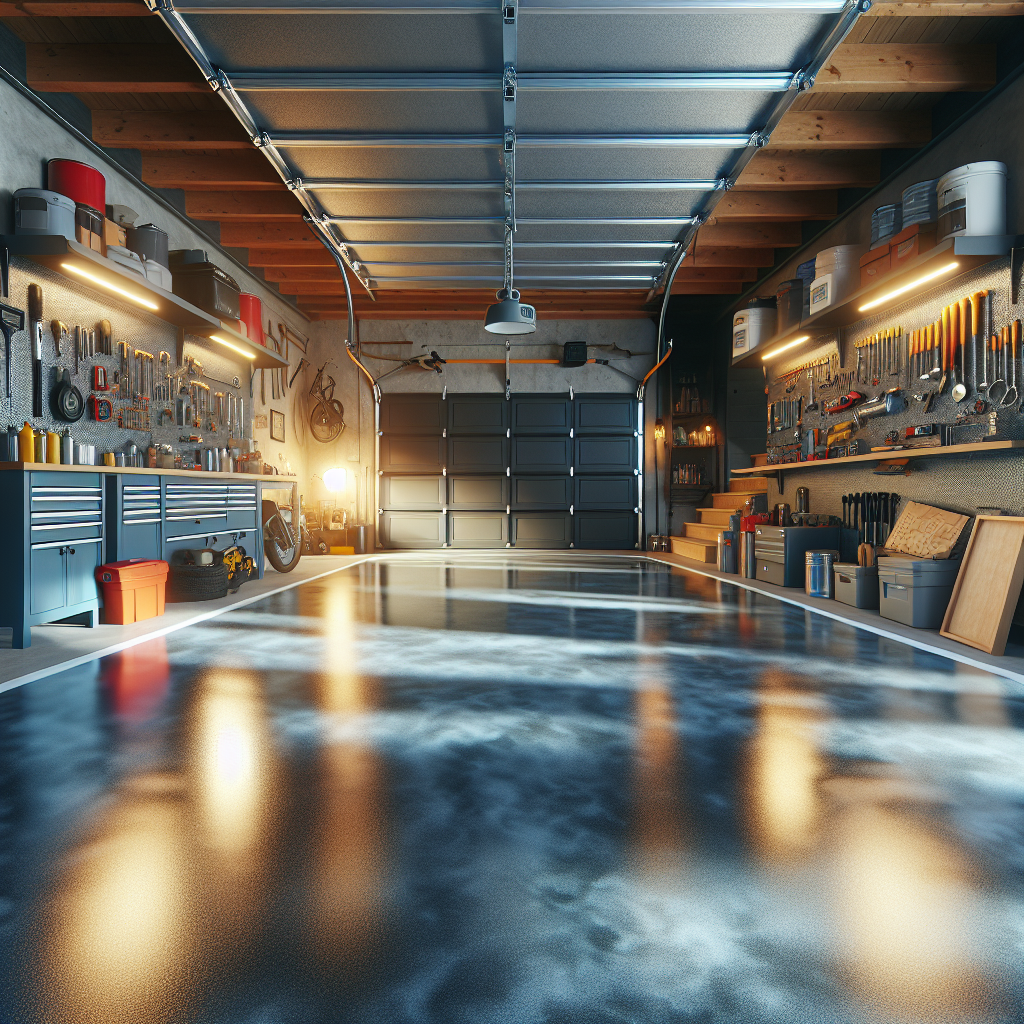

When considering garage floor epoxy applications, it’s essential to understand its versatility beyond the typical concrete surfaces. Garage floor epoxy is a durable and protective coating that enhances the aesthetic and functional aspects of various flooring materials. While it’s predominantly used on concrete, many homeowners wonder, can you use garage floor epoxy on plywood? The short answer is yes, but there are crucial factors to consider.

Epoxy coatings provide a robust, chemical-resistant surface, making them ideal for garages, workshops, and even residential areas. Here are some advantages:

- Durability: Epoxy creates a hard surface that withstands heavy traffic, spills, and impacts.

- Aesthetic Appeal: Available in various colors and finishes, epoxy can transform a dull floor into a visually striking one.

- Easy Maintenance: The non-porous surface resists stains and is easy to clean.

However, when using epoxy on plywood, proper preparation is vital. The plywood must be adequately primed and sealed to prevent moisture damage and ensure the epoxy adheres correctly. This is where expert installation plays a crucial role. Americas Industrial Coatings in Fort Lauderdale offers professional epoxy floor installation services tailored to your specific needs. Call Us Today for a Free Quote to find out how we can help you achieve the best results for your flooring project.

Can You Use Epoxy on Plywood Surfaces?

Using epoxy on plywood surfaces is a question many homeowners and DIY enthusiasts ask. The answer is nuanced, as it depends on several factors, including the intended use of the plywood and the specific conditions of the environment. Generally, epoxy can be applied to plywood, but there are important considerations to ensure successful results.

First, it’s crucial to understand that plywood is a porous material, and moisture can be a significant concern. If moisture seeps into the plywood, it can cause the epoxy to bubble or peel off. Therefore, before applying epoxy, it’s imperative to take the following steps:

- Preparation: Sand the plywood surface to create a smooth, even finish. This step enhances adhesion and ensures a better bond with the epoxy.

- Sealing: Apply a primer or sealer specifically designed for plywood. This will help lock out moisture and create a suitable surface for the epoxy.

- Application: Follow the manufacturer’s instructions for mixing and applying the epoxy. Ensure that the conditions are optimal—preferably a dry environment with controlled temperatures.

While it’s possible to use epoxy on plywood, it’s essential to assess the specific needs of your project. If you plan to use the area for heavy equipment or a high-traffic space, consider consulting with epoxy flooring professionals to ensure the best approach and materials are used.

Benefits of Using Epoxy on Plywood

Applying epoxy on plywood surfaces offers numerous advantages that can significantly enhance the durability and aesthetic appeal of your flooring. Understanding these benefits can help you make an informed decision for your project.

One of the most significant benefits of using epoxy on plywood is its durability. Epoxy coatings create a tough, resilient surface that withstands wear and tear, making it ideal for high-traffic areas. This added strength helps to protect the underlying plywood from damage caused by heavy loads, moisture, and spills.

Another advantage is the chemical resistance epoxy provides. If the plywood is used in environments where it may come into contact with various chemicals, such as in workshops or garages, epoxy acts as a barrier, preventing damage and deterioration.

Moreover, epoxy coatings are easy to clean and maintain. The smooth, non-porous surface of epoxy prevents dirt and grime buildup, making it simple to wipe down and keep clean. This feature is especially beneficial in spaces where hygiene is a priority.

Additionally, epoxy offers customization options. With a variety of colors and finishes available, you can achieve the desired look for your space. Whether you prefer a glossy sheen or a matte finish, epoxy can be tailored to match your aesthetic preferences.

Finally, the application of epoxy can enhance the value of your property. A well-finished epoxy floor not only looks professional but also signals to potential buyers that the property has been well-maintained and cared for.

Challenges and Risks of Epoxy on Plywood

While the benefits of using epoxy on plywood are numerous, it is essential to consider the challenges and risks involved in the application process. Being aware of these factors can help homeowners and contractors make informed decisions.

One of the primary challenges is the adhesion issue. Plywood can have varying levels of absorbency depending on its type and condition. If the surface is not adequately prepared, the epoxy may not bond effectively, leading to peeling or bubbling over time. Proper surface preparation, including sanding and cleaning, is crucial to achieving a strong bond.

Another risk is related to moisture content. Plywood that is not completely dry can trap moisture beneath the epoxy layer. This can result in mold growth, warping, and eventual failure of the epoxy coating. It is essential to check the moisture levels before application to ensure a successful installation.

Additionally, the <strong curing process of epoxy can pose challenges. Epoxy requires specific temperature and humidity conditions to cure properly. If the environment is too cold or humid, the curing process may be adversely affected, leading to a subpar finish or an incomplete cure.

Another consideration is the time and effort required for proper application. Applying epoxy on plywood is not a quick process; it involves multiple steps, including preparation, mixing, application, and curing. Each step must be executed meticulously to achieve the desired results, which can be time-consuming for DIY enthusiasts.

Lastly, while epoxy is durable, it is not impervious to damage. Heavy impacts or sharp objects can still cause chips or scratches. Therefore, it’s important to treat the surface with care to maintain its appearance and longevity.

Preparation and Application Tips for Epoxy

To ensure a successful epoxy application on plywood, proper preparation and application techniques are crucial. Following these tips can help achieve a durable and visually appealing finish.

First, start with surface preparation. The plywood must be clean, dry, and free from any dust, grease, or contaminants. Begin by thoroughly cleaning the surface with a suitable cleaner and then sand it lightly to create a rough texture that promotes adhesion. After sanding, vacuum or wipe the surface to remove any dust particles.

Next, check the moisture content of the plywood. Use a moisture meter to ensure that the wood is below 12% moisture content. If the wood is too moist, allow it to dry out completely before proceeding with the epoxy application.

When mixing the epoxy, follow the manufacturer’s instructions carefully. Precise mixing ratios are essential for a successful cure. Use a clean container and stir the resin and hardener thoroughly to ensure an even mixture, avoiding air bubbles.

During application, use a high-quality roller or brush for an even coat. Start in a corner and work your way out to avoid stepping on uncured areas. It’s recommended to apply two thin coats rather than one thick coat, allowing the first layer to cure completely before applying the second. This method enhances durability and creates a smoother finish.

After application, make sure to maintain the appropriate temperature and humidity levels as recommended by the epoxy manufacturer. This ensures proper curing and helps to avoid issues like bubbling or incomplete hardening.

Lastly, allow the epoxy to cure fully before moving furniture or placing heavy items on the surface. This waiting period is vital for ensuring the longevity and integrity of your epoxy floor.

Alternative Flooring Solutions for Plywood

While epoxy is a popular choice for finishing plywood surfaces, there are several alternative flooring solutions that you might consider, depending on your specific needs and preferences.

One viable option is vinyl flooring. Known for its durability and water resistance, vinyl can be easily installed over plywood and comes in a vast array of styles and colors. This makes it a versatile choice for both aesthetic and functional purposes. Additionally, vinyl flooring can withstand heavy foot traffic and spills, making it ideal for areas like garages and workshops.

Laminate flooring is another alternative that offers the look of hardwood or stone without the high maintenance. It consists of multiple layers, providing excellent durability and ease of installation. Laminate is also resistant to scratches, making it suitable for busy environments.

If you’re looking for a more eco-friendly option, consider bamboo flooring. Bamboo is a renewable resource and provides a unique aesthetic. It’s naturally durable and can be finished to withstand moisture, making it a suitable choice for various applications.

For a more rustic look, hardwood flooring can be a fantastic alternative. While generally more expensive, hardwood adds value to your home and can last a lifetime if properly cared for. It’s essential to ensure that the plywood subfloor is in excellent condition before installation.

Lastly, for those seeking a budget-friendly solution, carpet tiles provide a soft, comfortable surface that can be easily replaced if damaged. They come in various colors and patterns, allowing customization for your space.

Ultimately, choosing the right flooring solution will depend on your specific requirements and aesthetic preferences. If you’re considering your options for flooring over plywood, Call Us Today for a Free Quote and let our experts help you find the perfect solution.