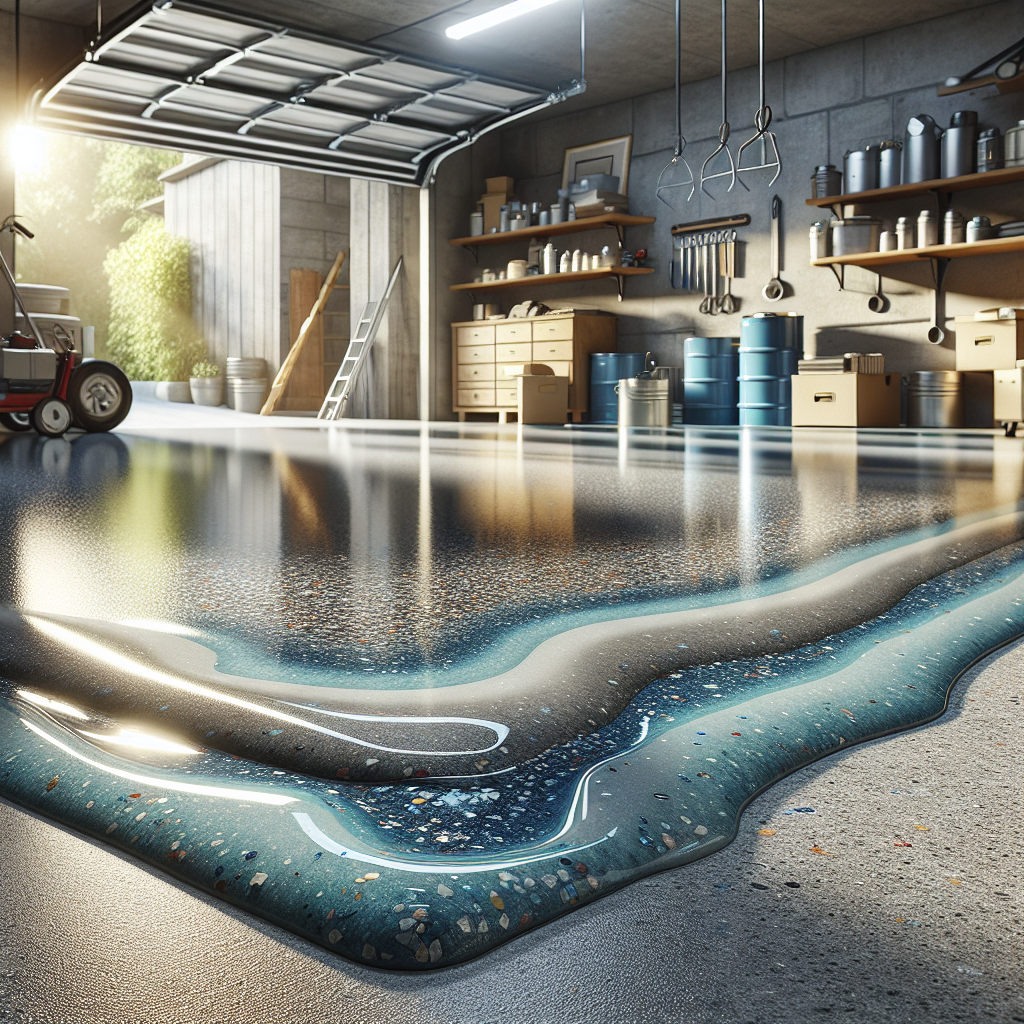

When considering a garage floor makeover, understanding how long it takes for garage floor epoxy to dry is crucial for planning your project. Epoxy flooring is a popular choice due to its durability and aesthetic appeal, but the drying time can vary based on several factors.

Typically, the initial curing time for garage floor epoxy can range from 6 to 12 hours before it can handle light foot traffic. However, for full curing and optimal hardness, you may need to allow up to 72 hours. To ensure the best results, consider the following factors:

- Temperature: Epoxy cures faster in warmer temperatures. Ideal conditions are usually between 70°F and 90°F.

- Humidity: High humidity can slow down the curing process, so it’s best to choose a dry day for application.

- Thickness of the application: Thicker layers of epoxy will take longer to dry than thinner applications.

- Type of epoxy: Different epoxy formulations have varying drying times, so be sure to check the manufacturer’s guidelines.

By paying attention to these factors, you can effectively manage your project timeline. If you’re looking for expert epoxy floor installation in Broward County, Call Us Today for a Free Quote and let our professionals handle your flooring needs!

Factors That Influence Epoxy Drying Duration

Understanding the factors that influence epoxy drying duration is essential for achieving the best results in your garage flooring project. Several variables can affect how quickly your epoxy cures, and being aware of these can help you plan accordingly.

Here are some of the key factors:

- Ambient Temperature: As mentioned previously, warmer temperatures speed up the curing process. Ideally, you should apply epoxy when the temperature is between 70°F and 90°F. When temperatures drop below this range, the drying time may significantly increase.

- Humidity Levels: High humidity can impede epoxy curing. When the air is saturated with moisture, it can slow down the evaporation of solvents in the epoxy, leading to longer drying times. Aim for a humidity level of below 70% for optimal results.

- Epoxy Mixture: The specific formulation of the epoxy you choose can also impact drying time. Some products are designed for faster curing, while others may take longer but offer increased durability.

- Thickness of Application: The thickness of the epoxy layer applied to the floor will affect the drying duration. Thicker layers take longer to cure than thinner applications, so it’s crucial to apply the right amount based on manufacturer recommendations.

- Ventilation: Proper airflow around the application area can promote quicker drying. Ensure that the garage is well-ventilated to facilitate the evaporation of solvents.

By taking these factors into account, you can better manage your project timeline and ensure a successful installation of your garage floor epoxy.

Different Stages of Epoxy Curing Process

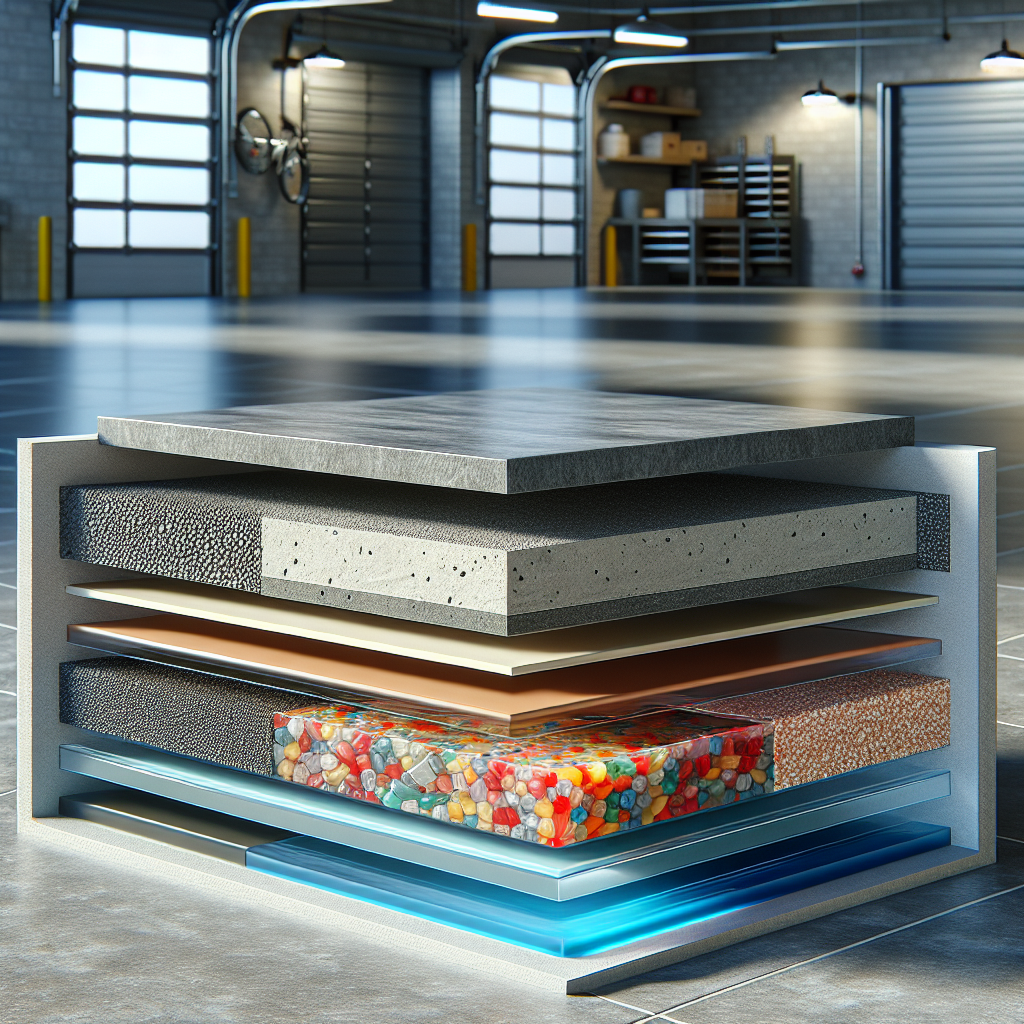

The epoxy curing process involves several distinct stages, each crucial for achieving a durable and long-lasting finish on your garage floor. Understanding these stages can help you monitor the progress and ensure that you allow adequate time for each phase.

Here are the primary stages of the epoxy curing process:

- Initial Set: This is the first stage, which typically occurs within 30 minutes to 2 hours after application. In this phase, the epoxy begins to harden and can no longer be manipulated. It is essential to avoid any traffic or disturbances during this period to prevent imperfections.

- Tack-Free Stage: Following the initial set, the epoxy enters the tack-free stage, which can last from 4 to 8 hours. During this time, the surface will feel dry to the touch but may still be soft beneath. It’s crucial to keep heavy objects off the surface to avoid indentations.

- Full Cure: This final stage can take anywhere from 3 to 7 days, depending on the specific product and environmental conditions. The epoxy continues to harden and gain strength, reaching its maximum durability at this point. It is vital to refrain from heavy usage during this time to ensure that the epoxy fully cures without any damage.

By familiarizing yourself with these stages, you can effectively manage your project’s timeline and ensure that your new epoxy garage floor is not only visually appealing but also durable and long-lasting.

How Temperature Affects Drying Time

The temperature in your garage or workspace plays a pivotal role in determining how long it takes for garage floor epoxy to dry. Understanding this relationship is essential for achieving optimal results during installation.

Here’s how temperature affects the drying time of epoxy:

- Higher Temperatures: Generally, warmer temperatures accelerate the drying process. When the temperature rises above 70°F (21°C), you can expect the epoxy to set more quickly. However, if it exceeds 90°F (32°C), the epoxy may cure too fast, which can lead to bubbles, uneven surfaces, and other defects.

- Lower Temperatures: Conversely, cooler temperatures can significantly slow down the drying time. If the temperature falls below 60°F (15°C), the epoxy may take much longer to cure, and in some cases, it may not set properly at all. This can lead to issues such as soft spots and inadequate bonding.

- Humidity Levels: While temperature is a critical factor, humidity also plays a role. High humidity levels can delay the evaporation of solvents in the epoxy, leading to an extended drying time. Ideally, aim for a humidity level of 40-60% for the best results.

Being mindful of the temperature and humidity in your workspace not only ensures a smoother installation process but also contributes to the longevity of your epoxy floor. Adjusting your project schedule to align with optimal environmental conditions can help achieve the desired finish.

Tips for Ensuring Optimal Drying Conditions

To guarantee that your garage floor epoxy dries effectively, it’s crucial to create the right environment. Here are some valuable tips for ensuring optimal drying conditions:

- Control the Temperature: Maintain a consistent temperature between 70°F and 80°F (21°C to 27°C) during the drying process. If necessary, use heaters or fans to stabilize the temperature in your garage.

- Monitor Humidity: Keeping humidity levels between 40% and 60% is essential. Use a dehumidifier if the air is too moist, as high humidity can slow down the drying time significantly.

- Ventilation: Ensure adequate ventilation in your workspace. Opening windows and using fans can help circulate air and reduce humidity levels, promoting quicker drying.

- Avoid Direct Sunlight: While warmth is beneficial, direct sunlight can cause uneven curing and surface defects. If possible, cover the floor with tarps or work during cooler parts of the day.

- Plan for Downtime: Consider scheduling your epoxy installation during a time when you can allow for extended drying periods, especially if conditions are not ideal. This will help avoid rushed applications and ensure a flawless finish.

By following these tips, you can create a controlled environment that supports the proper curing of your epoxy floor. Taking the time to prepare your workspace for optimal drying conditions will ultimately lead to a more durable and attractive finish.

Common Mistakes to Avoid During Drying Process

When it comes to applying and drying garage floor epoxy, certain missteps can hinder the final outcome. To achieve the best results, it’s essential to be aware of the common mistakes to avoid during the drying process:

- Skipping Surface Preparation: Failing to properly clean and prepare the floor can result in poor adhesion and an uneven finish. Always ensure the surface is free of dust, grease, and moisture before application.

- Not Following Manufacturer’s Instructions: Each epoxy product comes with specific guidelines regarding mixing ratios, application techniques, and drying times. Ignoring these instructions can lead to issues such as bubbling or peeling.

- Applying Too Thick a Layer: Over-applying epoxy can prolong drying times and may cause the surface to remain tacky. Aim for a thin, even coat to promote faster and more effective curing.

- Neglecting to Check Weather Conditions: Ignoring external factors like temperature and humidity can adversely affect the drying process. Always check the forecast before starting your project to ensure ideal conditions.

- Using the Wrong Tools: Employing improper tools for application can lead to streaks and uneven surfaces. Use a high-quality roller or squeegee designed specifically for epoxy applications.

By recognizing and avoiding these common pitfalls, you can significantly enhance the quality of your epoxy floor installation. If you’re ready to transform your garage with expert epoxy flooring, Call Us Today for a Free Quote!