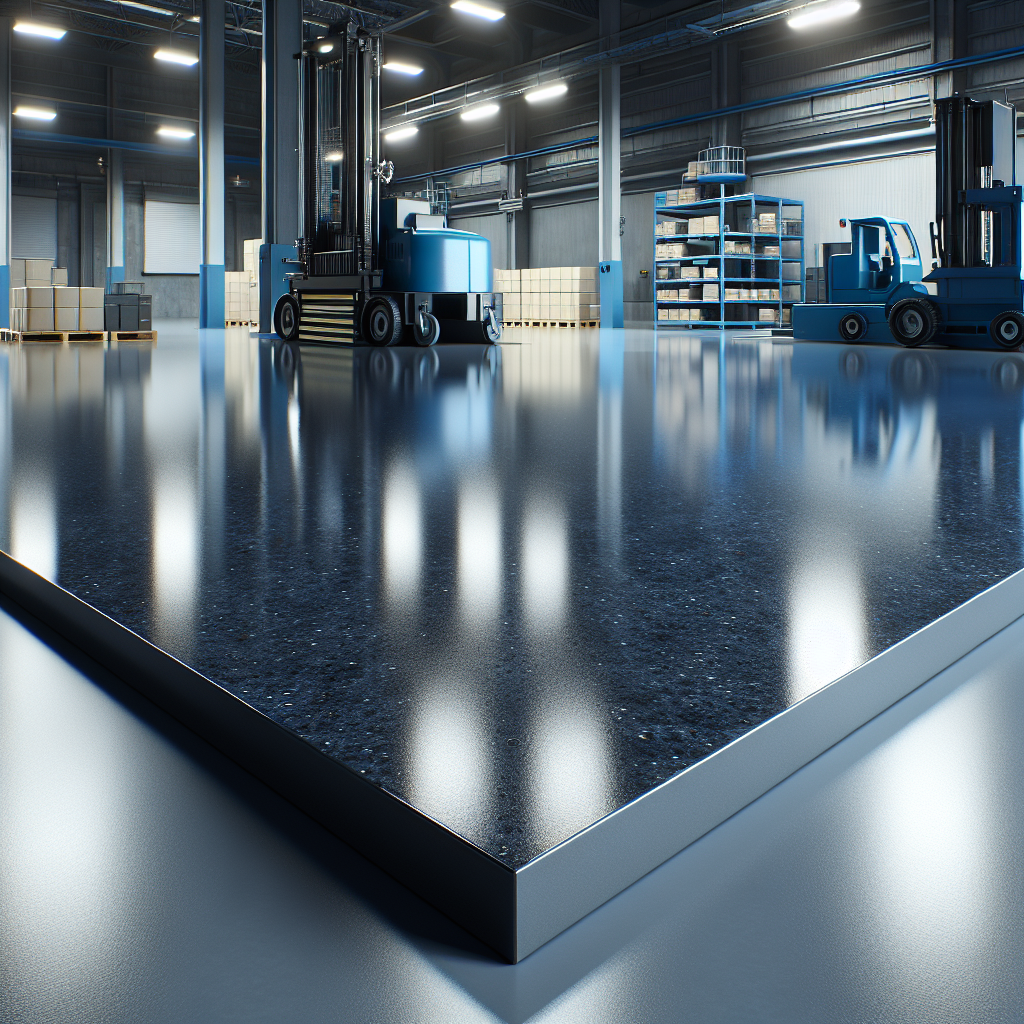

When it comes to flooring options, many homeowners and business owners often ask, “how hard is epoxy flooring?” The answer lies in understanding its remarkable durability and hardness. Epoxy flooring is created by combining resin and hardeners, resulting in a surface that is not only visually appealing but also incredibly strong.

One of the primary benefits of epoxy flooring is its impressive resistance to wear and tear. This makes it an excellent choice for high-traffic areas, such as:

- Garages

- Warehouses

- Retail stores

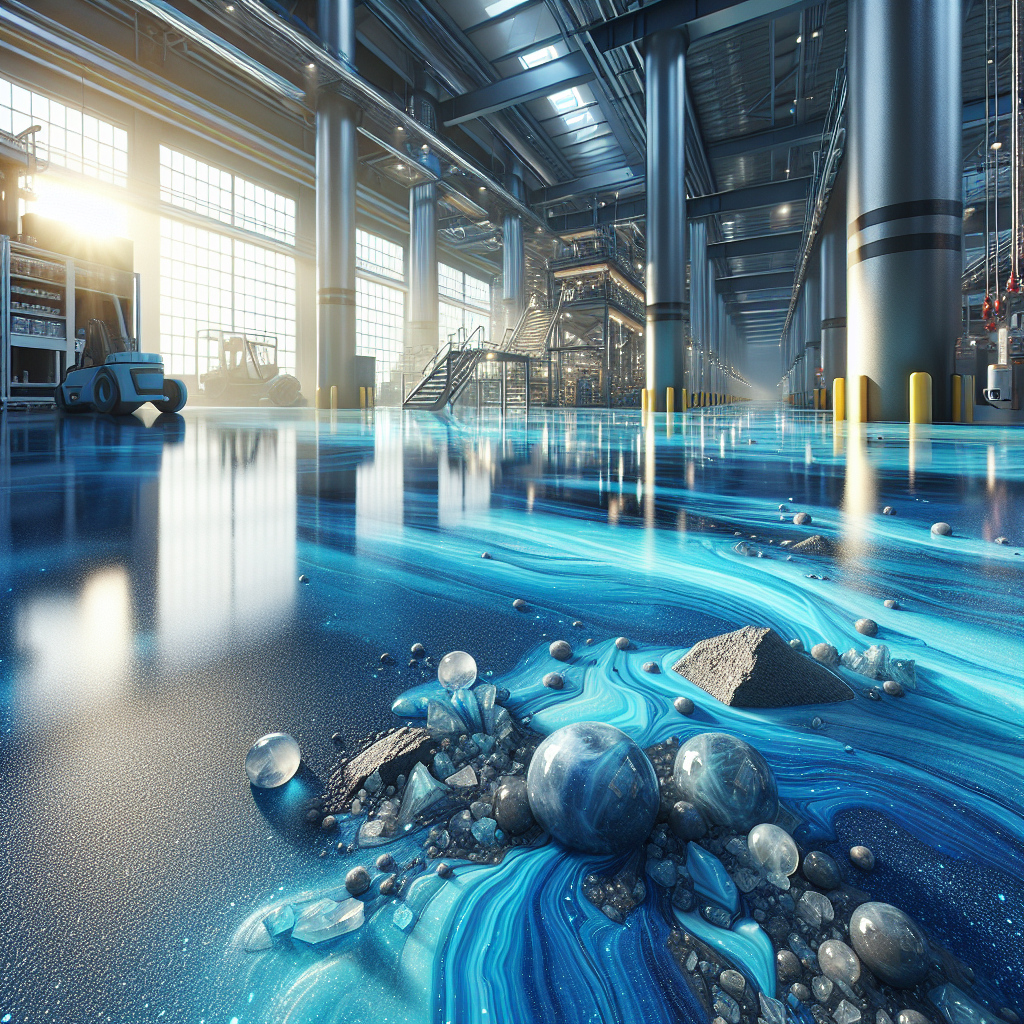

In addition to its durability, epoxy flooring can withstand various chemicals, spills, and stains, making it particularly suitable for industrial and commercial environments. This resilience ensures that your flooring retains its integrity over time, reducing the need for frequent repairs or replacements.

Furthermore, the hardness of epoxy flooring can often be measured on the Mohs scale, where it typically ranks around 5 to 6, indicating that it can resist scratches and impacts from everyday use. This characteristic enhances its value as a long-term flooring solution.

If you’re considering upgrading to epoxy flooring, you’ll be pleased to know that our team at Americas Industrial Coatings in Fort Lauderdale offers expert installation services tailored to your needs. Call Us Today for a Free Quote and discover how epoxy flooring can transform your space!

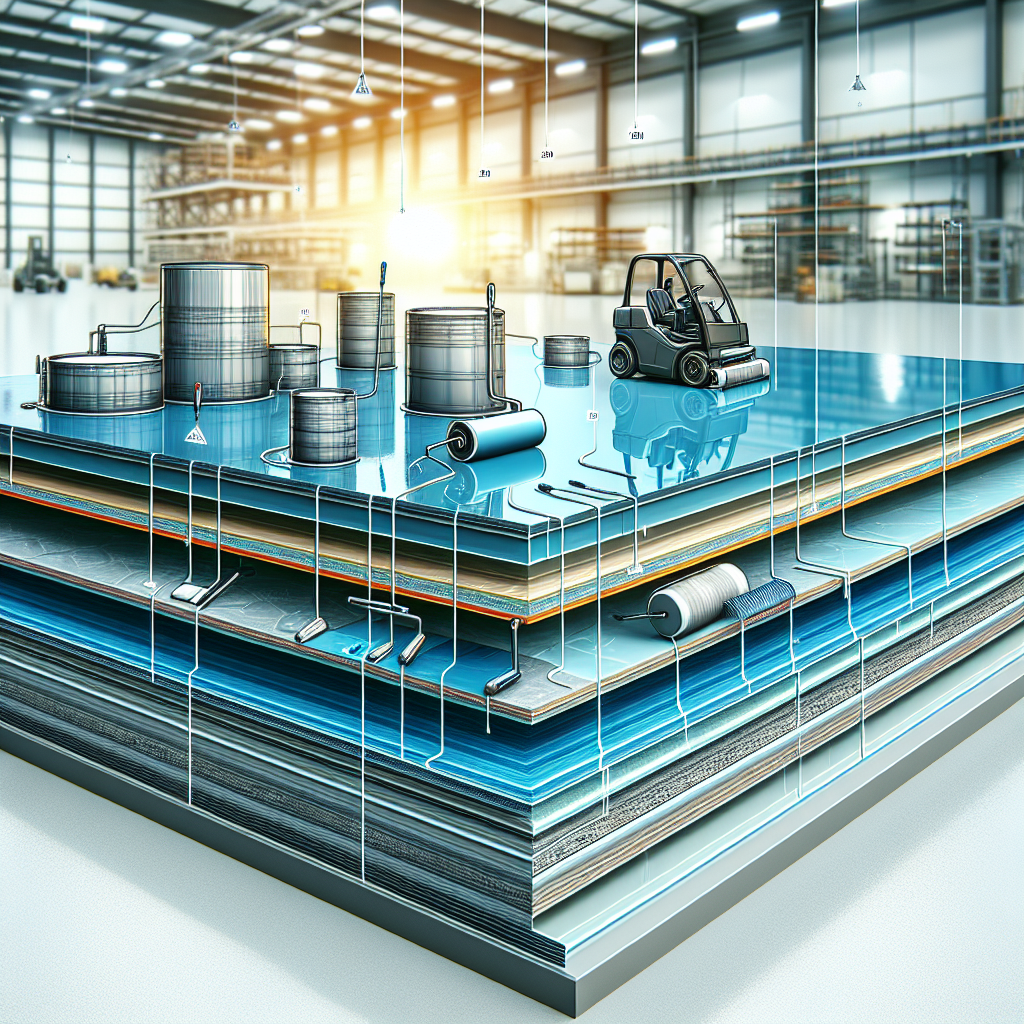

Factors Influencing the Hardness of Epoxy Floors

The hardness of epoxy floors can be influenced by several critical factors, each playing a significant role in the final outcome of the flooring system. Understanding these variables can help you make informed decisions when selecting an epoxy solution for your space.

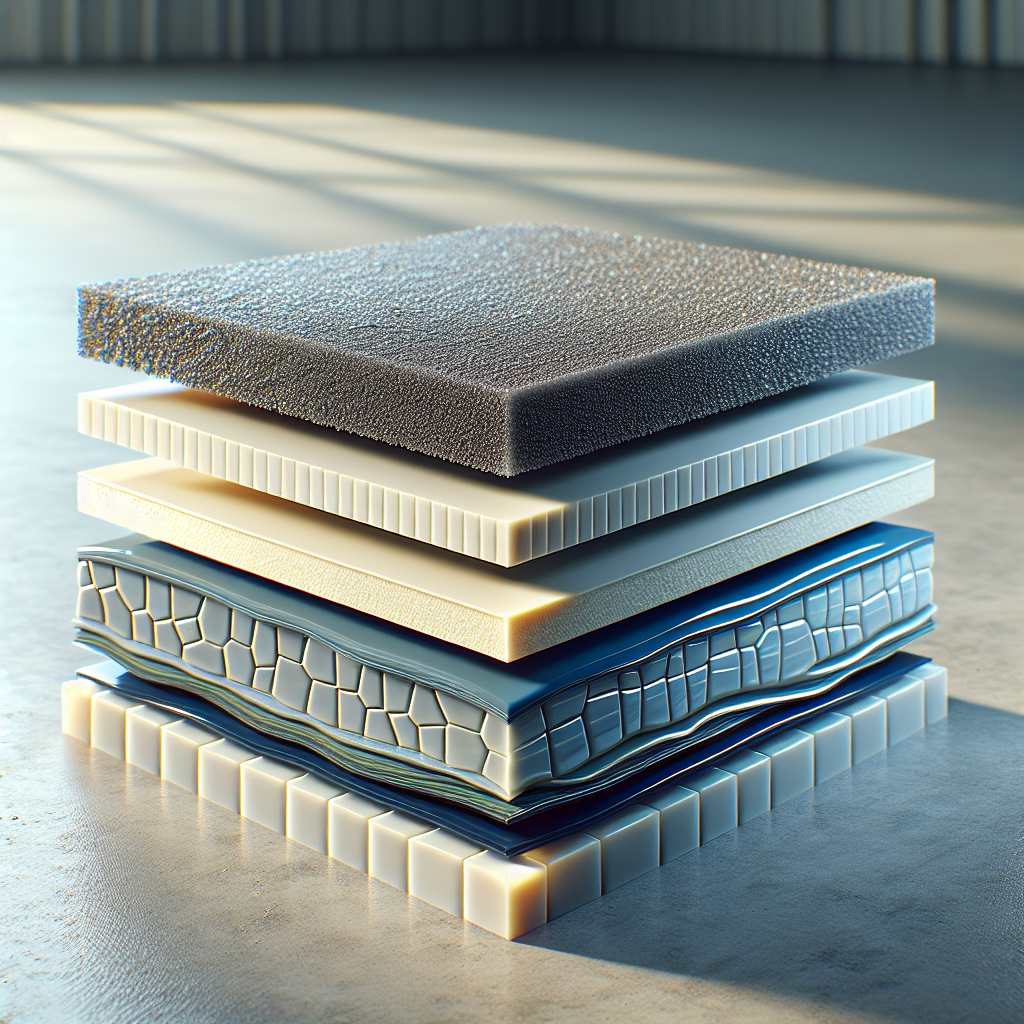

1. Type of Epoxy Resin: Different types of epoxy resins can affect the hardness. For instance, 100% solids epoxy provides a harder surface compared to solvent-based options, due to its higher density and absence of evaporative components.

2. Thickness of Application: The thickness of the epoxy layer plays a vital role in its overall hardness. A thicker application can lead to enhanced durability and resistance to impacts, making it a more robust flooring option.

3. Curing Conditions: The environment during the curing process, including temperature and humidity levels, can significantly affect the hardness of the epoxy. Ideal conditions promote a stronger bond and a more durable finish.

4. Additional Additives: Many epoxy systems allow for the inclusion of additives, such as hardening agents or fillers, which can change the chemical composition and improve hardness characteristics.

5. Substrate Preparation: Proper preparation of the substrate is crucial for achieving a hard, long-lasting surface. Any imperfections or contamination on the floor can lead to weak spots in the epoxy and reduce its overall hardness.

Knowing these factors will empower you to choose the right epoxy flooring system that meets your specific needs and ensures a durable, long-lasting surface.

Comparing Epoxy Flooring to Other Flooring Options

When considering flooring options, it’s essential to compare epoxy flooring with other popular materials to understand its distinct advantages and disadvantages. Here’s how epoxy stacks up against some common flooring choices:

1. Concrete: While concrete is a durable option, it lacks the seamless finish and protective features of epoxy. Epoxy coatings can enhance the appearance of concrete, providing a glossy finish and additional resistance to stains and chemicals.

2. Vinyl: Vinyl flooring is known for its affordability and ease of installation. However, it may not withstand heavy impacts or chemical spills as effectively as epoxy. Epoxy offers superior durability and can last significantly longer in high-traffic areas.

3. Tile: Tile flooring is aesthetically pleasing and available in various designs but can be prone to cracking and requires grout maintenance. In contrast, epoxy provides a seamless surface that is easy to clean and maintains its integrity over time.

4. Carpet: While carpet offers comfort and warmth, it is more susceptible to stains, allergens, and wear. Epoxy flooring, on the other hand, is resistant to moisture and stains, making it a more hygienic choice for industrial and commercial spaces.

5. Laminate: Laminate flooring is another budget-friendly option, but it can be less durable than epoxy. Epoxy flooring withstands heavy traffic and has better resistance to chemicals, making it ideal for garages, warehouses, and commercial facilities.

In summary, while each flooring option has its pros and cons, epoxy flooring stands out for its durability, ease of maintenance, and versatility, making it a superior choice for various applications.

Benefits of Installing Hard Epoxy Flooring

Installing hard epoxy flooring comes with a multitude of benefits that make it a preferred choice for both residential and commercial spaces. Here are some of the key advantages:

1. Durability: One of the most significant benefits of epoxy flooring is its exceptional durability. It can withstand heavy foot traffic, machinery, and even impacts without showing signs of wear and tear, making it ideal for garages, warehouses, and industrial facilities.

2. Resistance: Epoxy floors offer excellent resistance to a variety of substances, including chemicals, oils, and stains. This makes them perfect for environments where spills are common, ensuring that your floor remains intact and easy to clean.

3. Low Maintenance: Hard epoxy flooring requires minimal maintenance compared to other flooring options. A simple sweep and occasional mopping are usually all that’s needed to keep your floor looking pristine.

4. Aesthetics: With a glossy finish and a range of color options, epoxy flooring can enhance the overall appearance of any space. It can also be customized with patterns or designs to suit your specific needs and preferences.

5. Safety: Many epoxy flooring products are designed to be slip-resistant, providing a safer surface for walking, especially in commercial and industrial environments. This can help reduce accidents and increase workplace safety.

6. Environmentally Friendly: Epoxy flooring is often made from materials that are low in volatile organic compounds (VOCs), making it a more environmentally responsible choice compared to some other flooring options.

In conclusion, the installation of hard epoxy flooring offers numerous benefits, from durability and resistance to low maintenance and aesthetic appeal, making it a smart investment for any property.

Common Myths About Epoxy Flooring Hardness

Despite the growing popularity of epoxy flooring, several myths persist regarding its hardness and performance. Understanding the truth behind these misconceptions is essential for making informed decisions. Here are some common myths about epoxy flooring hardness:

1. Myth: Epoxy is the same as concrete. While epoxy can be applied over concrete, it is not the same material. Epoxy is a resin compound that forms a hard, durable surface when cured, whereas concrete is a mixture of cement, aggregates, and water. The two serve different purposes and have varying properties.

2. Myth: All epoxy floors are equally hard. Not all epoxy formulations are created equal. The hardness of epoxy flooring can vary based on the type of resin used and the specific application process. High-quality epoxy products are specifically designed to provide superior hardness and durability.

3. Myth: Epoxy flooring is prone to chipping and cracking. When properly installed, epoxy flooring is highly resistant to chipping and cracking. It can withstand heavy loads and impacts, making it a reliable choice for high-traffic areas. However, poor installation or low-quality materials can lead to issues.

4. Myth: Epoxy floors are slippery. While some epoxy flooring can be slippery when wet, many products are designed with slip-resistant additives that enhance traction. This feature makes epoxy floors a safe option for both residential and commercial environments.

5. Myth: Epoxy flooring is only for industrial spaces. Although epoxy is a favored choice in industrial settings, it is also suitable for residential applications. Homeowners increasingly choose epoxy for garages, basements, and even living areas due to its aesthetic versatility and durability.

By debunking these myths, potential buyers can better understand the true capabilities of epoxy flooring and make informed decisions that suit their needs.

Conclusion: Is Epoxy Flooring Right for You?

In evaluating whether epoxy flooring is the right choice for your space, several factors must be considered. First, the unique properties of epoxy—its hardness, durability, and resistance to stains and chemicals—make it an excellent option for a variety of environments, from commercial garages to residential basements.

Moreover, the aesthetic appeal of epoxy flooring cannot be overlooked. With a range of colors, finishes, and patterns available, you can customize your flooring to match your style while enjoying the robust performance that epoxy offers.

Another critical aspect to consider is maintenance. Epoxy floors are relatively low-maintenance, requiring only occasional cleaning to retain their shine and integrity. This quality makes them particularly attractive to busy homeowners and business owners alike.

However, it’s essential to ensure that the installation is performed by qualified professionals. A poorly installed epoxy floor may not yield the desirable results, leading to issues like bubbling or peeling. This is where expert services come into play, ensuring that your investment pays off in both durability and appearance.

If you’re contemplating whether epoxy flooring is the right solution for your needs, don’t hesitate to reach out for professional advice. Call Us Today for a Free Quote at Americas Industrial Coatings and let our experts guide you through your options!