Welcome to our insightful review of The Floor Emporium, a prominent name in the flooring industry that has garnered significant attention over the years. If you’re considering a flooring project, whether for a residential or commercial space, it’s essential to know if this company can meet your expectations. In this article, we delve into the features, benefits, and customer experiences that define The Floor Emporium.

Known for its diverse range of flooring solutions, The Floor Emporium offers an extensive selection of materials, from hardwood and laminate to vinyl and tile. Each product is crafted to cater to different aesthetic preferences and durability needs, ensuring that every customer finds the perfect fit for their space. The company prides itself on combining quality with affordability, making it a popular choice for those looking to upgrade their floors without breaking the bank.

Beyond the rich variety of products, The Floor Emporium is also recognized for its exceptional customer service. The team is committed to guiding clients through the selection process, ensuring that each customer makes an informed decision tailored to their specific needs. This personalized approach has earned the company a reputation for reliability and customer satisfaction.

To get started on your flooring journey, Call Us Today for a Free Quote and explore the possibilities that The Floor Emporium offers. Our team at Americas Industrial Coatings is here to assist you every step of the way.

Product Range and Quality

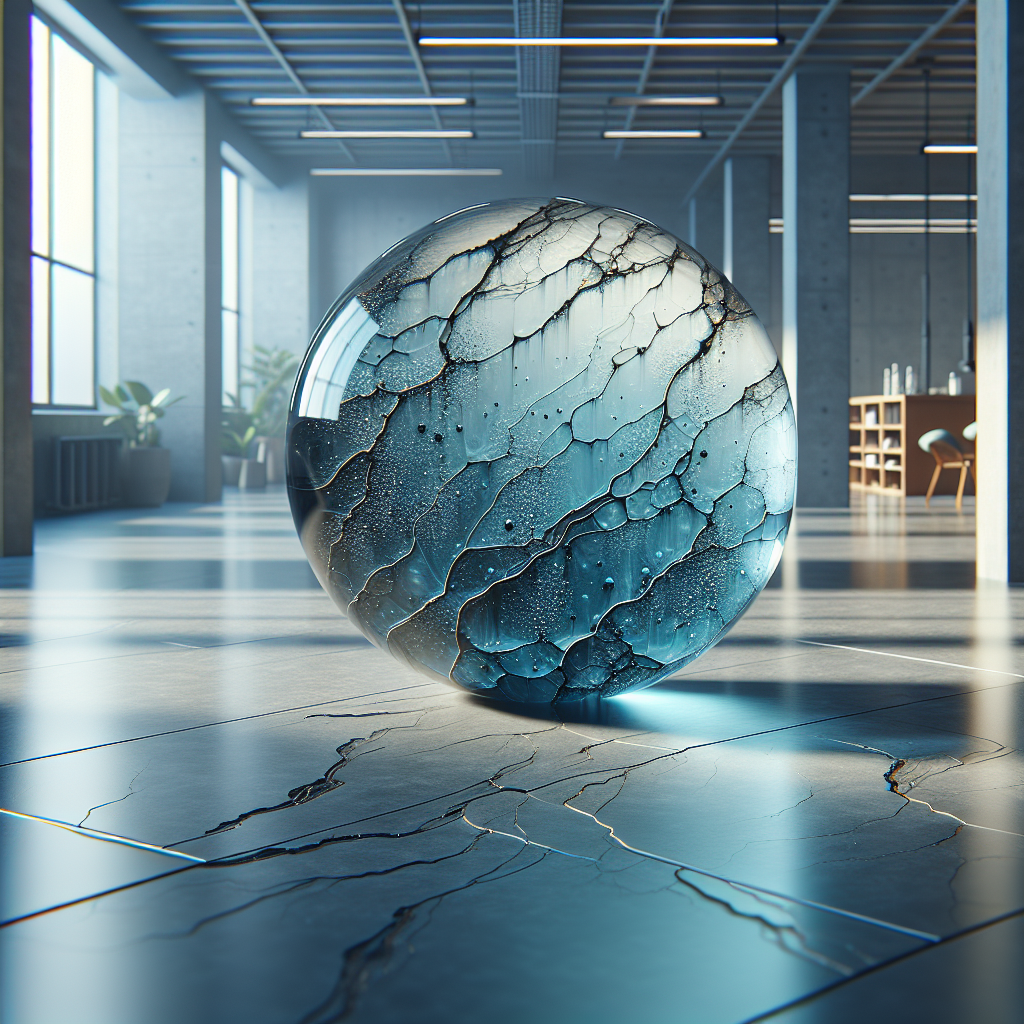

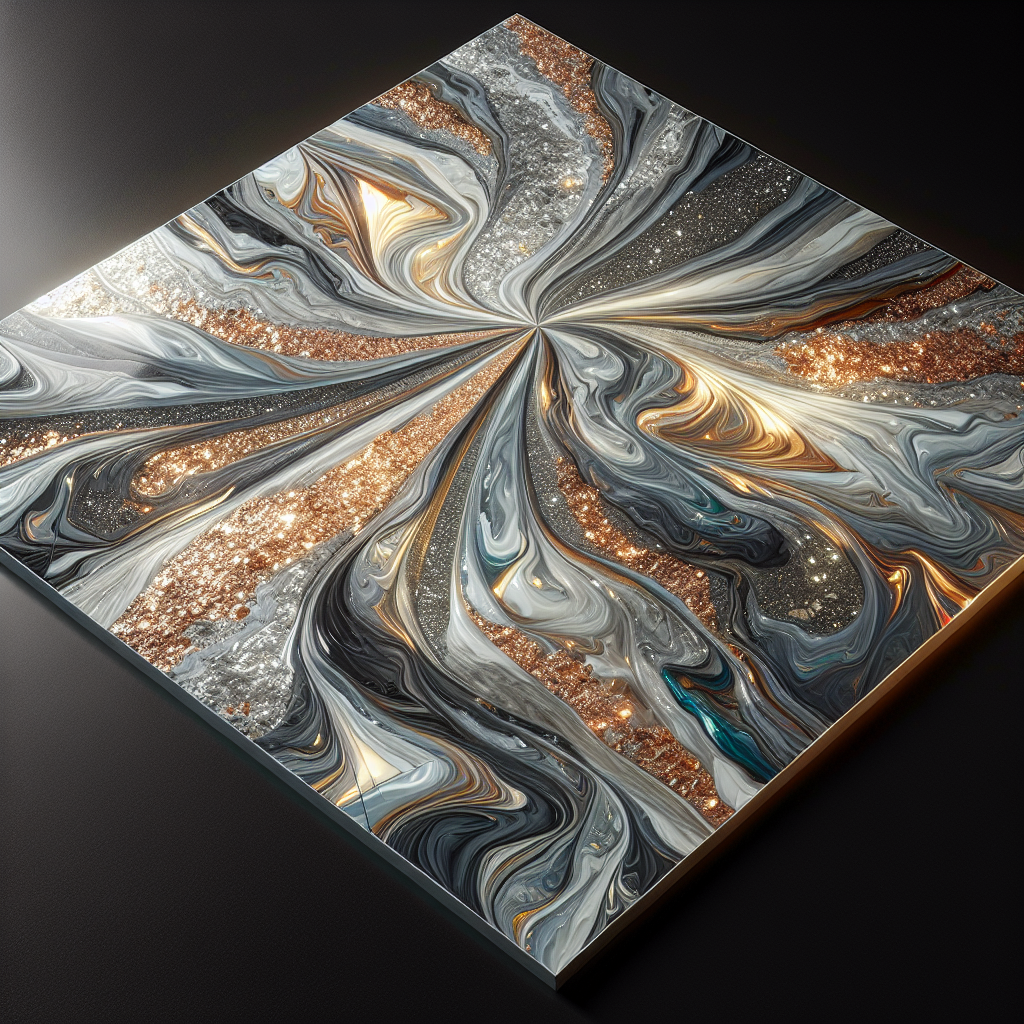

The Floor Emporium takes pride in offering a comprehensive array of flooring options to suit diverse tastes and requirements. Their product range includes premium materials such as hardwood, laminate, vinyl, and tile, each available in a variety of styles, colors, and finishes. This extensive selection ensures that every customer can find flooring that aligns with their aesthetic vision and functional needs.

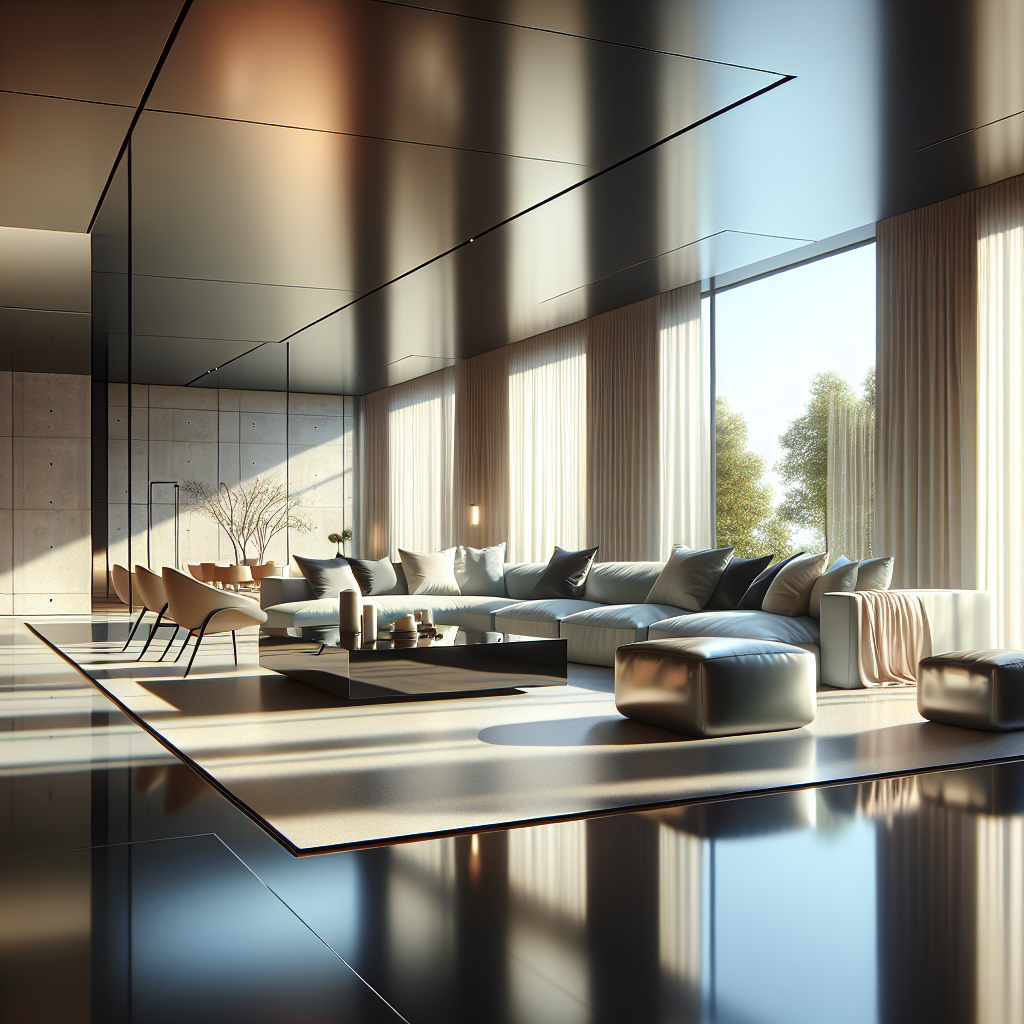

One of the standout offerings is their hardwood flooring, renowned for its timeless appeal and durability. Customers can choose from different wood species, finishes, and plank sizes, allowing for a customizable and unique installation. For those seeking a more budget-friendly alternative, their laminate flooring mimics the look of natural wood or stone, providing a durable and low-maintenance option.

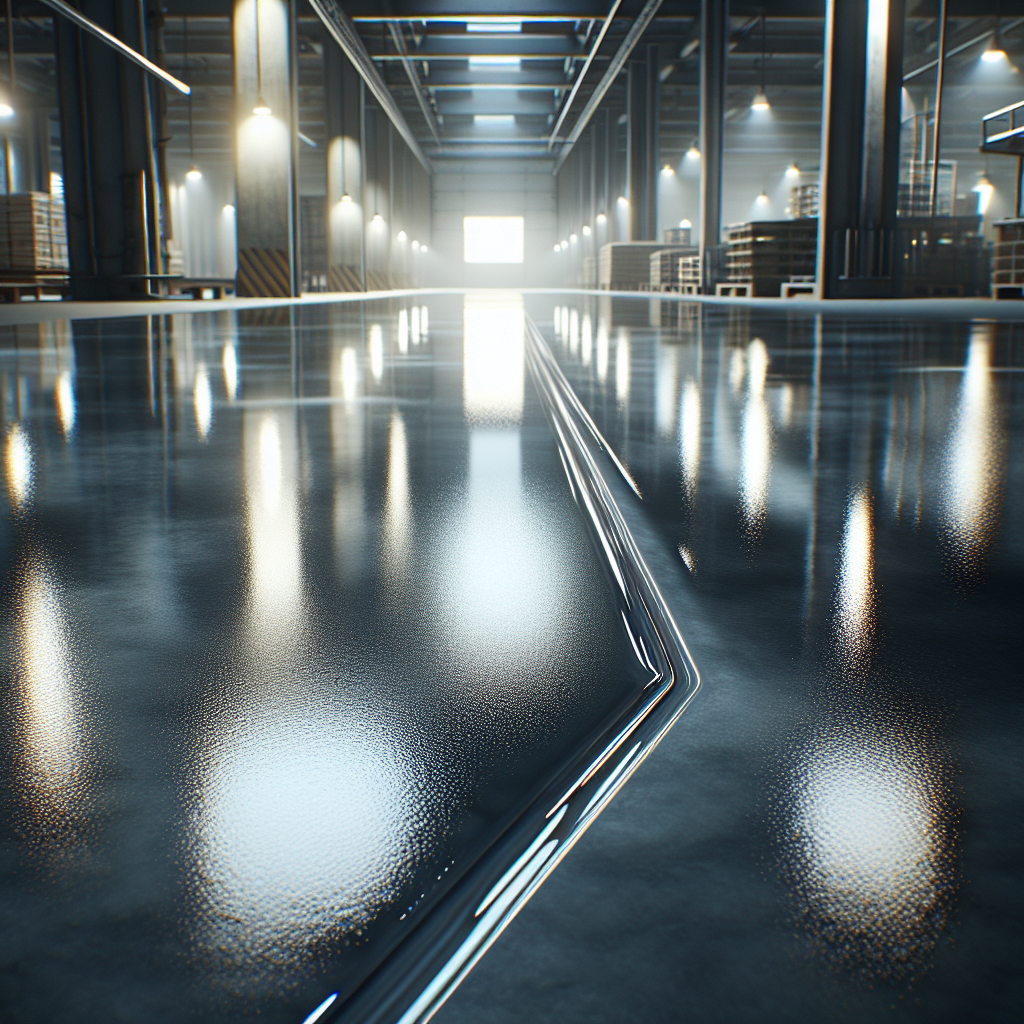

Vinyl flooring at The Floor Emporium is another popular choice, thanks to its resilience and versatility. Available in both sheet and luxury vinyl plank formats, this option is ideal for areas prone to moisture, such as kitchens and bathrooms. Additionally, their tile collection features a wide range of ceramic and porcelain tiles, perfect for creating elegant and durable surfaces.

The Floor Emporium’s commitment to quality is evident in their rigorous selection process, ensuring that each product meets high standards of durability and aesthetic appeal. This dedication to excellence not only enhances the beauty of any space but also guarantees long-lasting performance, making it a preferred choice for discerning customers.

Customer Service Experience

At The Floor Emporium, the customer service experience is designed to be seamless and satisfying from start to finish. Upon entering their showroom or visiting their website, customers are greeted by a team of knowledgeable and friendly staff who are eager to assist with any inquiries. This welcoming atmosphere sets the tone for an engaging and informative interaction.

One of the key highlights of their customer service is the personalized approach they take with each client. The Floor Emporium offers free consultations where experts assess the specific needs and preferences of the customer. This tailored service ensures that clients receive recommendations that are best suited to their project, enhancing the overall satisfaction with the final outcome.

The transparent communication throughout the purchasing and installation process further elevates the experience. Customers are kept informed about timelines, potential challenges, and progress updates, fostering a sense of trust and reliability. Moreover, their post-installation support is commendable, as they offer guidance on maintenance and care to ensure the longevity of the flooring.

Reviews from previous clients frequently highlight the professionalism and efficiency of the service team. Many customers appreciate the staff’s ability to address concerns promptly and effectively, reinforcing The Floor Emporium’s reputation as a customer-centric business. Such dedication to service excellence not only strengthens customer loyalty but also encourages new clients to choose them for their flooring needs.

Pricing and Value for Money

When considering “The Floor Emporium review“, pricing and value for money are crucial factors that often determine customer satisfaction. The Floor Emporium strives to offer competitive pricing across its wide range of flooring options, ensuring that clients receive quality products without breaking the bank.

The extensive selection includes a variety of materials such as hardwood, laminate, vinyl, and tile, each available at different price points to accommodate various budgets. This diversity allows customers to find flooring that not only meets their aesthetic preferences but also aligns with their financial constraints. The Floor Emporium frequently runs promotions and discounts, which provide further savings, making it an attractive choice for budget-conscious shoppers.

In terms of value for money, the quality of the materials and the expertise of the installation teams contribute significantly to the overall worth of their offerings. Clients can expect durable and long-lasting flooring solutions that enhance the beauty and functionality of their spaces. The company also stands behind its products and services with warranties, providing peace of mind and demonstrating confidence in their offerings.

Customer testimonials often highlight the balance between cost and quality, with many praising the Emporium for delivering exceptional value. This positive feedback underscores the company’s commitment to providing affordable yet high-quality flooring solutions that meet the diverse needs of its clientele. The combination of competitive pricing, quality products, and excellent service positions The Floor Emporium as a favorable option in the market.

Customer Reviews and Feedback

In the realm of “The Floor Emporium review“, customer reviews and feedback serve as invaluable resources for prospective buyers. These reviews offer genuine insights into the experiences of past clients, shedding light on the quality and reliability of the products and services provided by The Floor Emporium.

Overall, the feedback from customers is predominantly positive, with many praising the company for its wide selection of flooring options and professional installation services. Customers appreciate the knowledgeable staff who are well-equipped to guide them through the selection process, ensuring that they find the perfect flooring to meet their needs. Additionally, the installation teams are frequently commended for their efficiency and skill, resulting in seamless and aesthetically pleasing results.

- Quality of Products: Many reviews highlight the durability and style of the flooring choices, emphasizing that the materials stand the test of time.

- Customer Service: The staff’s friendly and helpful demeanor is often mentioned, with clients expressing gratitude for the personalized attention and advice they received.

- Installation Process: Clients frequently note the fast and professional installation, appreciating the minimal disruption to their daily lives.

Of course, no business is without its critics, and The Floor Emporium is no exception. Some feedback points to issues such as scheduling delays or communication challenges. However, the company appears proactive in addressing grievances, often reaching out to resolve any concerns raised by customers.

In sum, the collective voice of the customer reviews paints a picture of a company dedicated to delivering high-quality flooring solutions with commendable service, reinforcing The Floor Emporium’s reputation as a trusted name in the industry.

Final Verdict on The Floor Emporium

After a thorough analysis of “The Floor Emporium review“, it becomes evident that this establishment stands out as a reliable choice for those seeking quality flooring solutions. With an extensive range of products, from hardwood to laminate and everything in between, the store caters to a wide array of tastes and requirements. The emphasis on quality, coupled with attentive customer service, makes The Floor Emporium a sought-after destination for homeowners and businesses alike.

One of the most notable strengths of The Floor Emporium is its commitment to customer satisfaction. Reviews and feedback consistently highlight the company’s dedication to meeting client expectations through personalized service and professional installation. The knowledgeable staff and skilled installation teams ensure that each project is executed with precision, resulting in long-lasting and visually appealing flooring.

While minor issues such as scheduling hiccups have been reported, the company’s proactive approach to resolving concerns demonstrates a commitment to maintaining its reputation and fostering customer loyalty. This dedication to improvement is a strong indicator of a business that values its clients and is willing to adapt to ensure their satisfaction.

In conclusion, The Floor Emporium offers a comprehensive flooring experience that balances quality, style, and service. For those in search of reliable flooring solutions, it is worth considering this reputable establishment. To experience these benefits for yourself, call us today for a free quote and discover how The Floor Emporium can transform your space with their expert solutions.