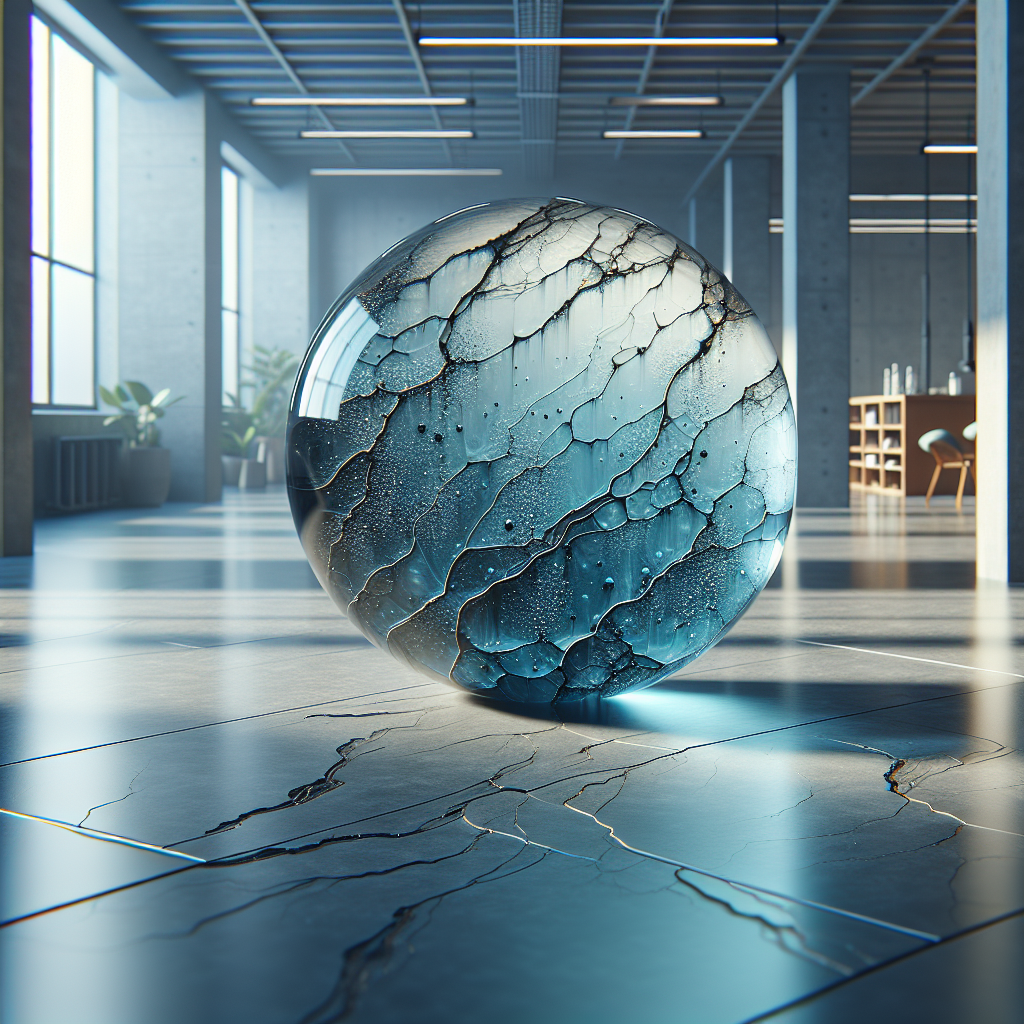

Epoxy floor coatings are renowned for their durability and aesthetic appeal, making them a popular choice for both residential and industrial settings. However, like any material, they are not immune to damage. Understanding the causes of cracks in epoxy floor coatings is essential for effective repair and prevention. Cracks can arise due to various factors, including improper installation, substrate issues, or excessive load stress. When the substrate beneath the epoxy is not adequately prepared, it can lead to an uneven surface that compromises the integrity of the coating.

Environmental factors also play a crucial role. For instance, fluctuations in temperature and humidity can cause the epoxy to expand and contract, leading to stress and eventual cracking. Additionally, if the epoxy is applied in too thick of layers, it may not cure properly, resulting in a brittle coating prone to cracking.

Regular maintenance and inspections can help identify early signs of cracking, allowing for timely intervention. By understanding these underlying causes, property owners and facility managers can take proactive steps to ensure their floors remain in top condition.

For comprehensive advice tailored to your specific needs, call us today for a free quote and let our experts guide you on the best practices for maintaining your epoxy floors.

Common Causes of Epoxy Coating Cracks

Understanding the common causes of epoxy floor coating cracks is critical for prevention and effective maintenance. One of the primary reasons for cracking is improper surface preparation. Before applying epoxy, the substrate must be clean, dry, and free from contaminants. If these steps are skipped or inadequately performed, it can lead to weak adhesion and eventual cracking.

Another frequent cause is thermal expansion and contraction. Epoxy coatings are susceptible to temperature changes, and if applied in environments with extreme fluctuations, they can expand and contract, leading to stress fractures. This is particularly evident in areas where the temperature can vary significantly between day and night or across different seasons.

Additionally, structural issues within the building can contribute to epoxy floor coating cracks. If the underlying concrete shifts or settles over time, it may cause the epoxy layer to crack. This is often exacerbated by heavy loads or traffic, which apply constant pressure to the flooring.

Lastly, using an improper mix ratio of the epoxy components can compromise its strength and flexibility. It’s essential to follow manufacturer guidelines closely to ensure that the epoxy cures correctly.

By recognizing these common causes, you can take proactive measures to prevent cracks in your epoxy floor coating, ensuring longevity and performance.

Preventing Cracks in Epoxy Floors

Preventing cracks in epoxy floors requires a strategic approach starting from the very beginning of the installation process. To minimize the risk of cracks, ensure thorough surface preparation. This means cleaning the substrate meticulously and ensuring it is both dry and level. Any existing cracks or imperfections in the concrete should be repaired before applying the epoxy.

It’s also crucial to control the environment during application. Epoxy coatings are best applied in stable temperature conditions. Ideally, the ambient temperature should be between 60°F and 80°F. Avoid applying epoxy during times of extreme temperature fluctuations, as this can lead to expansion and contraction, which may cause cracking.

Moreover, consider using high-quality epoxy products that are designed to withstand specific environmental conditions. There are formulations available that offer increased flexibility and durability, which can be particularly beneficial in areas subject to heavy loads or traffic.

Another preventive measure involves incorporating expansion joints into the flooring design. These joints can absorb movements in the floor and help prevent stress from being transferred to the epoxy coating, thus reducing the likelihood of cracking.

Finally, regular maintenance and inspections of the flooring can help identify potential issues before they develop into significant problems. By taking these preventive steps, you can extend the lifespan of your epoxy floors and maintain their aesthetic appeal and functionality.

Quick Repair Techniques for Epoxy Cracks

Addressing cracks in epoxy floors swiftly is crucial to maintaining the floor’s integrity and appearance. One of the most effective quick repair techniques involves using an epoxy filler. This material is specifically formulated to bond well with existing epoxy surfaces. Begin by cleaning the cracked area thoroughly to remove any debris or dust that could affect adhesion.

Once cleaned, apply the epoxy filler directly into the crack using a putty knife, ensuring it is evenly distributed. This method is ideal for small to medium-sized cracks and can usually be completed within a few hours, depending on the curing time of the filler used.

For larger cracks, consider the injection method. This involves injecting a low-viscosity epoxy resin into the crack, which can penetrate deeply and form a strong bond. The injection method is particularly effective when the crack is deep or if it extends through the entire thickness of the epoxy layer.

In some cases, if the crack is extensive, it might be necessary to recoat the entire affected area. This involves sanding the surface lightly to create a profile for the new epoxy layer to adhere to, followed by the application of a fresh coat of epoxy. This approach not only repairs the crack but also helps in blending the repair seamlessly with the rest of the floor.

These quick repair techniques ensure that your epoxy floor maintains its durability and aesthetic appeal, preventing further damage and extending the floor’s lifespan.

Tools Needed for Epoxy Crack Repair

Having the right tools is essential for effectively repairing cracks in epoxy floor coatings. The process is streamlined and more efficient when equipped with the proper equipment, ensuring a professional finish. Here’s a list of essential tools you’ll need:

- Putty Knife: A versatile tool used for applying epoxy filler into cracks. Its flat edge helps to smooth and level the filler with the surrounding floor surface.

- Epoxy Mixing Container: A durable container is necessary for mixing epoxy resin and hardener. Ensure it is clean and free from contaminants to avoid compromising the epoxy mix.

- Electric Drill with Mixing Paddle: For larger batches of epoxy, an electric drill fitted with a mixing paddle ensures a thorough blend of the resin and hardener, which is crucial for the curing process.

- Crack Injection Gun: This tool is used for the injection method, allowing precise application of low-viscosity epoxy into deeper cracks.

- Sandpaper or Grinder: Preparing the crack area by lightly sanding or grinding ensures better adhesion of the epoxy filler or coating.

- Protective Gear: Safety glasses, gloves, and a mask are essential to protect yourself from dust and fumes during the repair process.

With these tools at your disposal, you’ll be well-prepared to tackle epoxy crack repairs efficiently, ensuring a seamless and durable result. Proper preparation with the right tools not only eases the repair process but also enhances the quality and longevity of the repaired surface.

Maintaining Your Epoxy Floor Coating

Once you have successfully repaired cracks in your *epoxy floor coating*, maintaining the surface is crucial to ensure its longevity and pristine appearance. Regular maintenance not only keeps the floor looking new but also enhances its durability against future wear and tear.

**Routine Cleaning:** Sweep or vacuum the floor regularly to remove dust and debris that can cause surface scratches. Use a soft mop with a mild detergent and warm water to clean any spills or stains. Avoid using harsh chemicals or abrasive cleaning tools, as they can damage the epoxy surface.

**Preventive Measures:** Place protective pads under heavy furniture to prevent denting or scratching. Use mats or rugs in high-traffic areas to reduce wear. Ensure that any spills, especially oil or chemical-based, are cleaned immediately to prevent staining.

**Periodic Inspection:** Regularly inspect the floor for signs of damage or wear. Catching issues early can prevent minor problems from escalating into major repairs. Address small scratches or dents promptly with an epoxy touch-up kit.

**Re-Coating:** Depending on the traffic and exposure your floor experiences, consider re-coating the epoxy every few years. This fresh layer will restore the gloss and protect the underlying coating from further damage.

By following these maintenance tips, your epoxy floor will remain in top condition, reflecting its original shine and resilience. For professional advice or assistance with your epoxy flooring needs, call us today for a free quote and ensure your floors receive the best care possible.