Epoxy garage floors are rapidly becoming a popular choice for homeowners and businesses alike due to their ability to provide a durable and visually appealing surface. But what does an epoxy garage floor do? At its core, an epoxy garage floor is a protective coating applied over concrete that enhances its strength and aesthetic appeal. The epoxy resin forms a hard, glossy finish that is not only attractive but also resistant to stains, chemicals, and abrasions.

When considering the installation of an epoxy floor, it’s essential to understand its key benefits:

- Durability: Epoxy floors can withstand heavy loads and resist impacts, making them ideal for garages that house vehicles and tools.

- Easy Maintenance: The smooth surface allows for easy cleaning, requiring just a simple mop and mild detergent to maintain its shine.

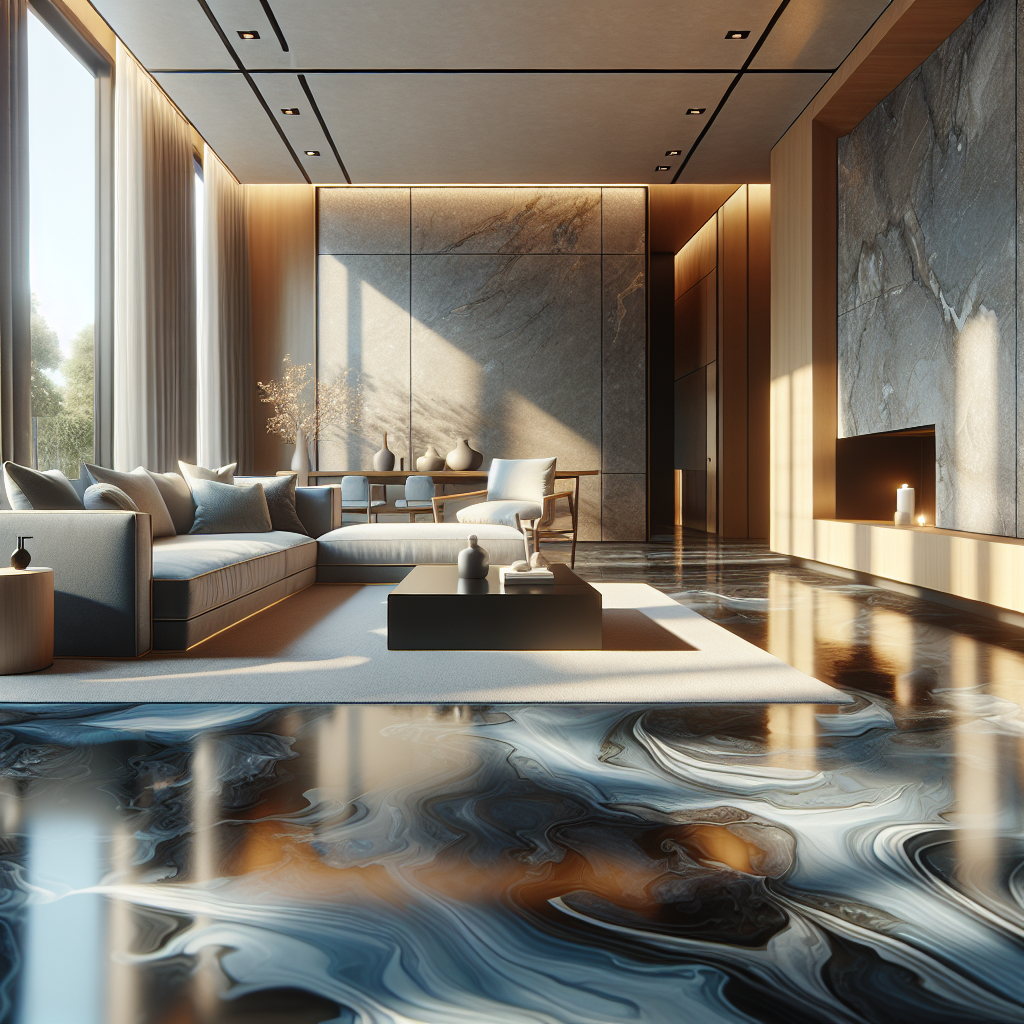

- Aesthetic Variety: Epoxy flooring comes in various colors and finishes, allowing you to customize your garage space to fit your style.

In addition to these benefits, an epoxy garage floor can significantly enhance the overall value of your property. If you’re looking for a reliable solution to upgrade your garage, call us today for a free quote at Americas Industrial Coatings. Our expert team in Fort Lauderdale is ready to assist you with top-notch epoxy floor installation in Broward County, Florida.

Benefits of Installing an Epoxy Garage Floor

Installing an epoxy garage floor offers a multitude of advantages that go beyond simple aesthetics. These benefits make epoxy flooring a smart investment for both residential and commercial spaces. Here are some of the top benefits of installing an epoxy garage floor:

- Enhanced Durability: Epoxy is known for its toughness and resilience. It can withstand heavy traffic, resist cracking, and endure impacts, making it perfect for garages and workshops.

- Chemical Resistance: Garages often serve as a workspace where spills from oils, chemicals, and other substances can occur. An epoxy floor provides a robust barrier against these spills, preventing damage to the underlying concrete.

- Safety Features: Many epoxy coatings can be enhanced with anti-slip additives, providing a safer surface that reduces the risk of slips and falls, especially in wet conditions.

- Improved Aesthetics: Available in a range of colors and finishes, epoxy flooring can transform a dull garage into a vibrant, professional-looking space. This not only boosts the visual appeal but can also increase the property value.

- Easy Maintenance: Unlike traditional concrete floors, epoxy surfaces are seamless and non-porous, making them easier to clean and maintain. Regular sweeping and occasional mopping are usually all that’s needed to keep the floor looking new.

Incorporating an epoxy garage floor can significantly enhance the functionality and appearance of your space, making it a worthwhile consideration for any property owner.

How Epoxy Garage Floors Enhance Durability

When it comes to flooring solutions, durability is a critical factor, especially in high-traffic areas like garages. Epoxy garage floors are renowned for their exceptional durability, and here’s how they achieve it:

- Strong Bonding: Epoxy coatings form a strong bond with the concrete substrate, creating a seamless surface that is less likely to crack or chip under pressure. This strong adhesion is crucial in ensuring that the floor can withstand heavy loads and impacts without deteriorating.

- Resistance to Wear and Tear: Unlike traditional concrete, epoxy floors are formulated to resist abrasion, making them ideal for garages where vehicles, tools, and equipment are frequently used. This resistance to wear means that your floor will maintain its appearance and functionality for years to come.

- Temperature Tolerance: Epoxy flooring can endure a wide range of temperatures without losing its structural integrity. This characteristic is especially important in climates with extreme weather conditions, as it prevents expansion and contraction that can lead to cracking.

- Impact Resistance: Whether it’s a dropped tool or a heavy object, epoxy floors are designed to withstand impacts without damage. This makes them an excellent choice for garages where such incidents are common.

- Long Lifespan: With proper installation and maintenance, epoxy garage floors can last for over a decade, providing a long-term flooring solution that outperforms many alternatives.

The combination of these factors ensures that an epoxy garage floor is not only a smart choice for durability but also a practical investment for homeowners looking to enhance the longevity of their garage space.

Maintenance Tips for Epoxy Garage Floors

Maintaining an epoxy garage floor is essential to ensure its longevity and appearance. Fortunately, epoxy floors are relatively low-maintenance compared to other flooring options. Here are some effective maintenance tips to keep your epoxy garage floor in top condition:

- Regular Cleaning: Sweep or vacuum the surface regularly to remove dirt, dust, and debris. For deeper cleaning, use a mild detergent mixed with warm water. Avoid using abrasive cleaners as they can scratch the surface.

- Spot Cleaning: Immediately clean any spills, especially oil or chemicals, to prevent staining. Use a soft cloth or paper towel to blot the area and a suitable cleaner to remove any residue.

- Use Mats and Rugs: Placing mats in high-traffic areas can help prevent wear and tear. Additionally, using mats under vehicles can catch drips and spills that could otherwise stain the epoxy surface.

- Avoid Harsh Chemicals: While epoxy floors are resistant to many substances, it’s best to avoid harsh solvents or acidic cleaners that can degrade the epoxy over time.

- Periodic Inspections: Regularly inspect the floor for any signs of damage or wear. Addressing minor issues promptly can prevent them from developing into more significant problems.

By following these simple maintenance tips, you can ensure that your epoxy garage floor remains not only durable but also visually appealing for years to come. Taking proactive steps to care for your flooring will contribute to its overall performance and longevity.

Common Myths About Epoxy Garage Floors

Despite the growing popularity of epoxy garage floors, several misconceptions persist that can mislead homeowners. Understanding the truth behind these myths is crucial for anyone considering this flooring option. Here are some common myths about epoxy garage floors:

- Myth 1: Epoxy Floors are Slippery: Many believe that epoxy floors are dangerously slippery, especially when wet. In reality, epoxy coatings can be formulated with anti-slip additives that enhance traction, making them safe for garage use.

- Myth 2: Epoxy Floors are Only for Commercial Spaces: While epoxy is commonly used in commercial settings, it is equally beneficial for residential garages. Its durability and aesthetic appeal make it a great choice for homeowners looking to enhance their garage space.

- Myth 3: Installation is a DIY Project: Although some may attempt to install epoxy floors themselves, achieving a professional finish requires skill and experience. Improper installation can lead to peeling or bubbling, negating the benefits of the epoxy.

- Myth 4: Epoxy Floors are Not Durable: On the contrary, when properly installed and maintained, epoxy floors are highly durable and resistant to chemicals, stains, and heavy foot traffic. They can last for many years with minimal wear.

- Myth 5: Color Options are Limited: Many believe that epoxy flooring comes only in basic colors. In fact, epoxy coatings are available in a wide variety of colors and finishes, allowing homeowners to customize their garage to match their style.

By debunking these myths, homeowners can make informed decisions about installing epoxy garage floors, ensuring they reap the full benefits of this innovative flooring solution.

Choosing the Right Epoxy Garage Floor Installation Service

When it comes to upgrading your garage with an epoxy floor, selecting the right installation service is paramount to achieving the desired results. A professional installer not only ensures the quality of the work but also provides valuable insights into the best materials and techniques for your specific needs. Here are some key factors to consider when choosing an epoxy garage floor installation service:

- Experience and Expertise: Look for a company with a proven track record in epoxy floor installation. Experienced professionals will have the knowledge to handle various challenges and deliver high-quality results.

- Reputation and Reviews: Research customer reviews and testimonials to gauge the reputation of the service provider. Positive feedback from previous clients is a good indicator of reliability and customer satisfaction.

- Range of Services: Ensure the contractor offers a comprehensive range of services, including surface preparation, application, and post-installation support. A full-service provider can guide you through the entire process, from selection to maintenance.

- Quality Materials: Inquire about the types of epoxy materials the installer uses. High-quality epoxy will enhance durability and aesthetics, so it’s essential to choose a provider that prioritizes quality.

- Warranty and Support: A reputable installation service should offer a warranty on their work. This not only protects your investment but also demonstrates their confidence in their services.

By taking the time to evaluate these factors, you can find a reliable epoxy garage floor installation service that meets your needs. Call Us Today for a Free Quote and let America’s Industrial Coatings in Fort Lauderdale help you transform your garage with expert epoxy floor installation!