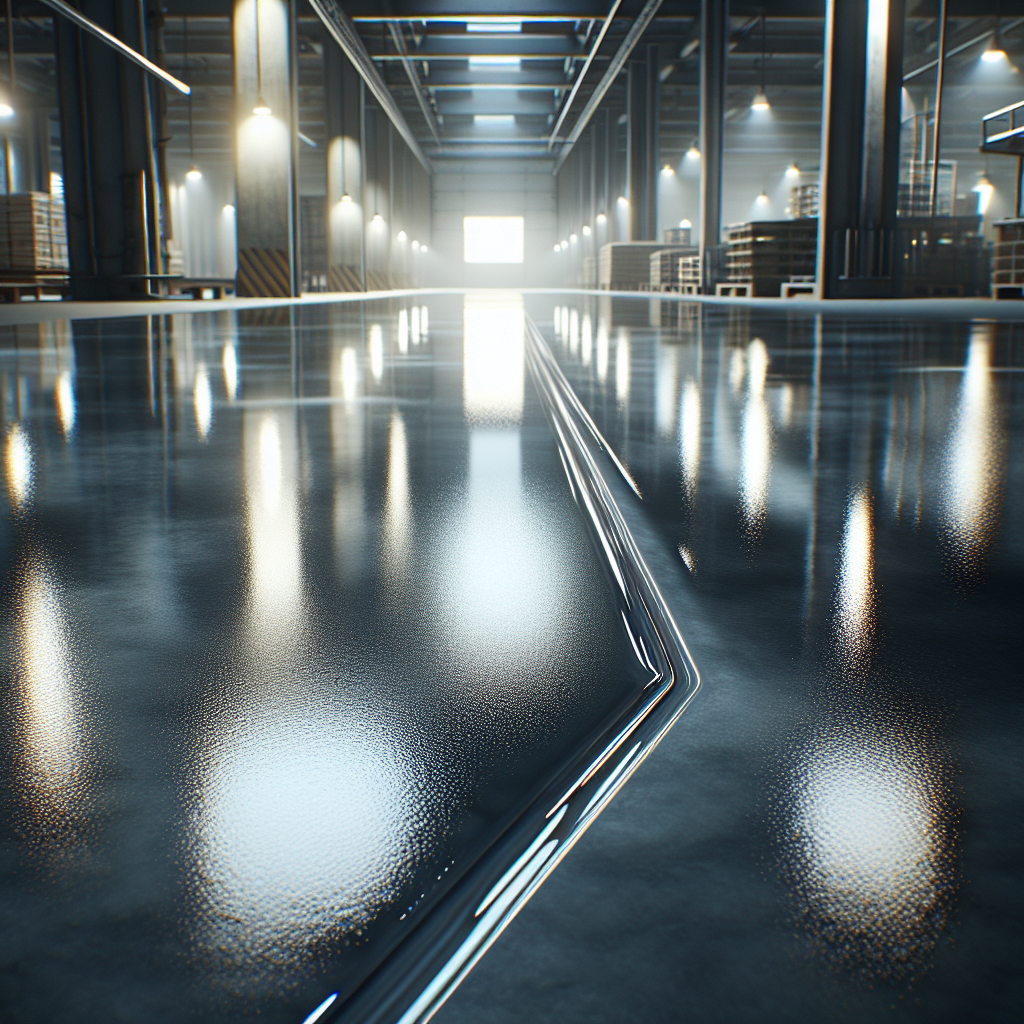

In the world of flooring, metallic epoxy flooring stands out as an innovative and visually striking option. It combines durability with a unique, glossy appearance that mimics the look of polished marble or granite. This type of flooring is created by mixing metallic pigments with epoxy resin, resulting in a three-dimensional, dynamic look that can transform any space into a work of art.

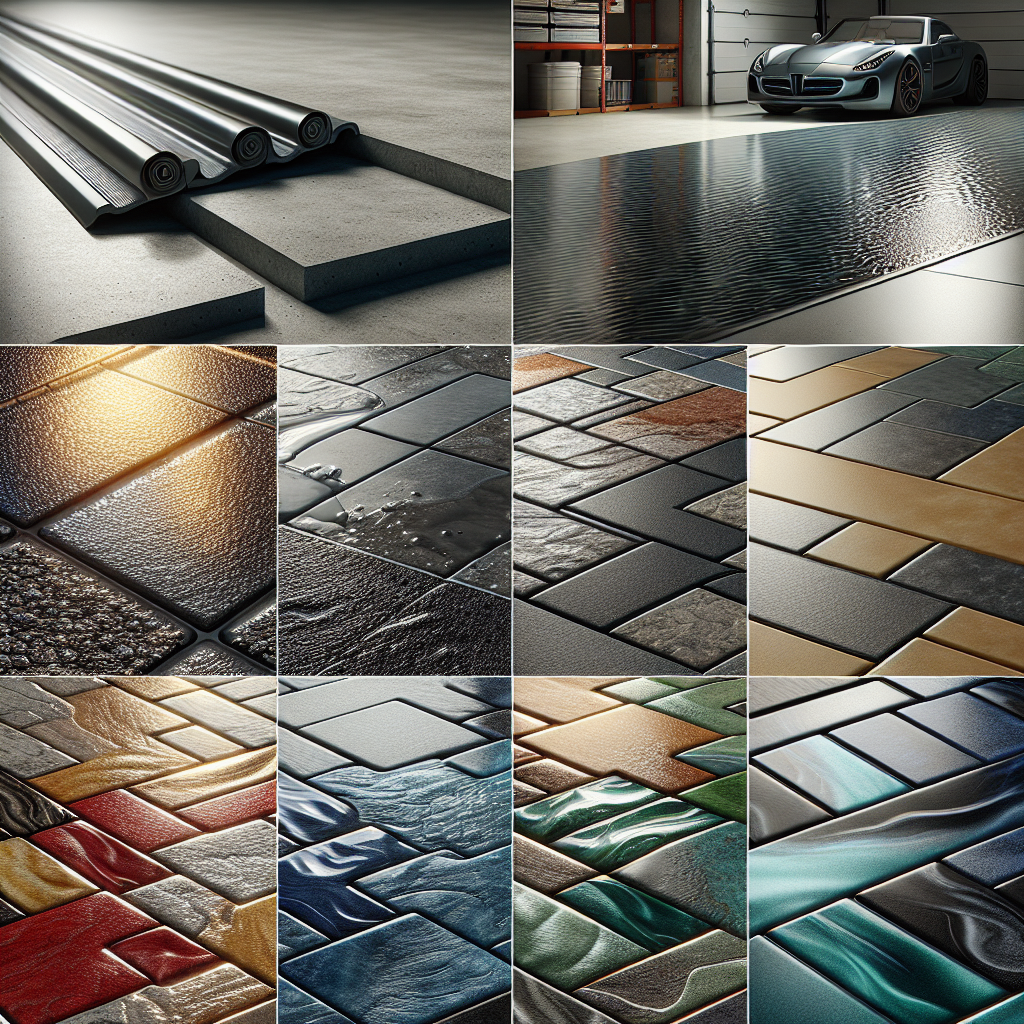

One of the main attractions of metallic epoxy flooring is its versatility. Whether you’re aiming for an industrial chic look in a commercial setting or a sleek, modern vibe in your home, this flooring can adapt to various styles and preferences. The application process allows for a wide range of colors and patterns, making it an excellent choice for those who want a personalized touch.

Despite its aesthetic appeal, it’s essential to weigh the pros and cons of metallic epoxy flooring to determine if it’s the right choice for your needs. Factors such as maintenance, installation complexity, and cost are crucial to consider. This flooring option offers a seamless, durable surface, but it requires professional installation to ensure the best results.

Are you ready to explore the possibilities of metallic epoxy flooring for your space? Call us today for a free quote and let Americas Industrial Coatings guide you towards making an informed decision that aligns with your vision and requirements.

Advantages of Metallic Epoxy Floors

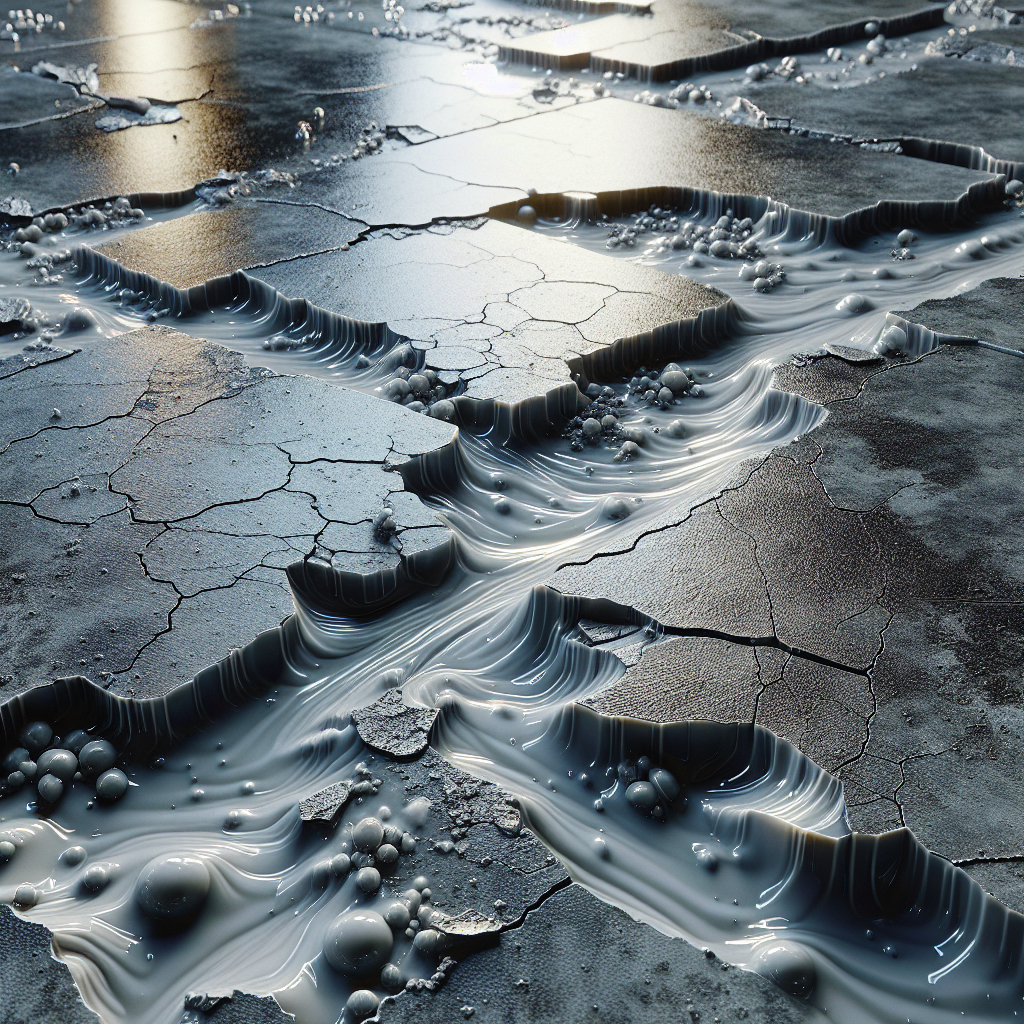

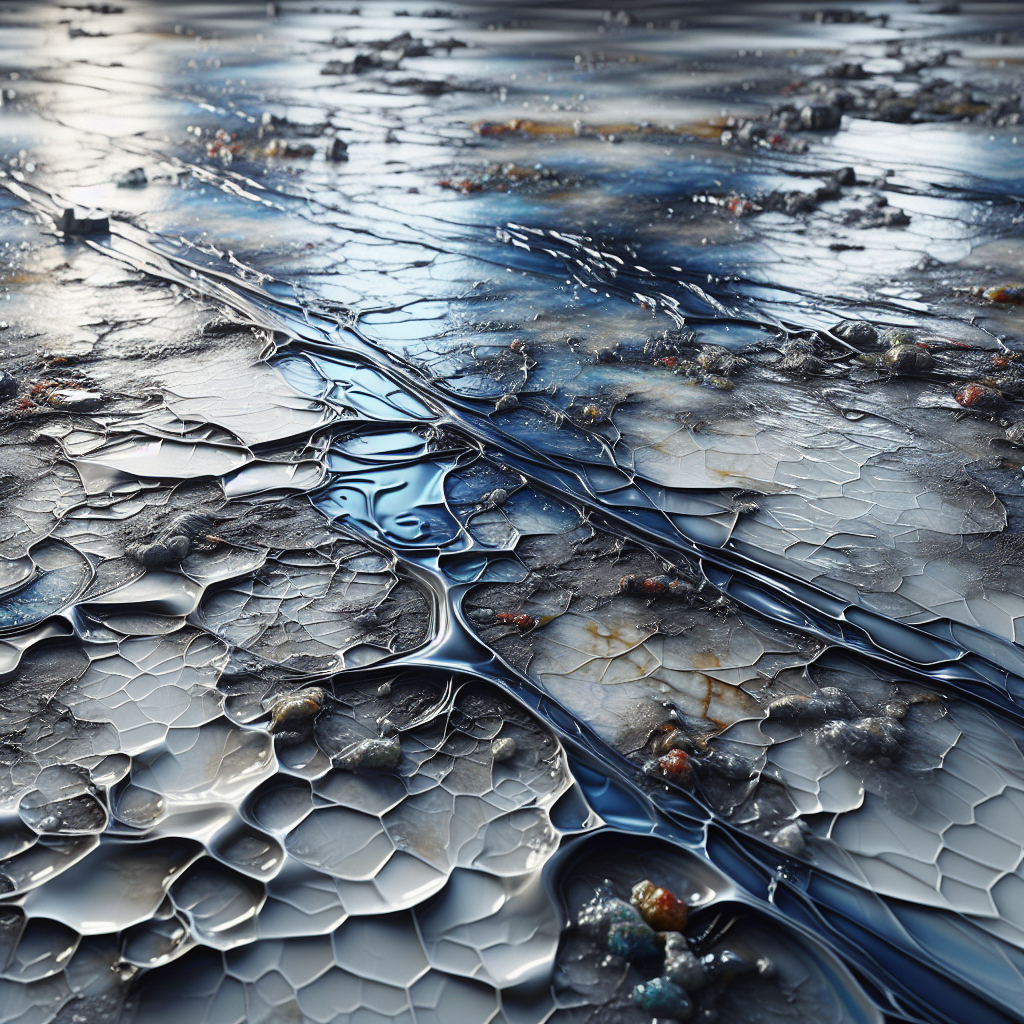

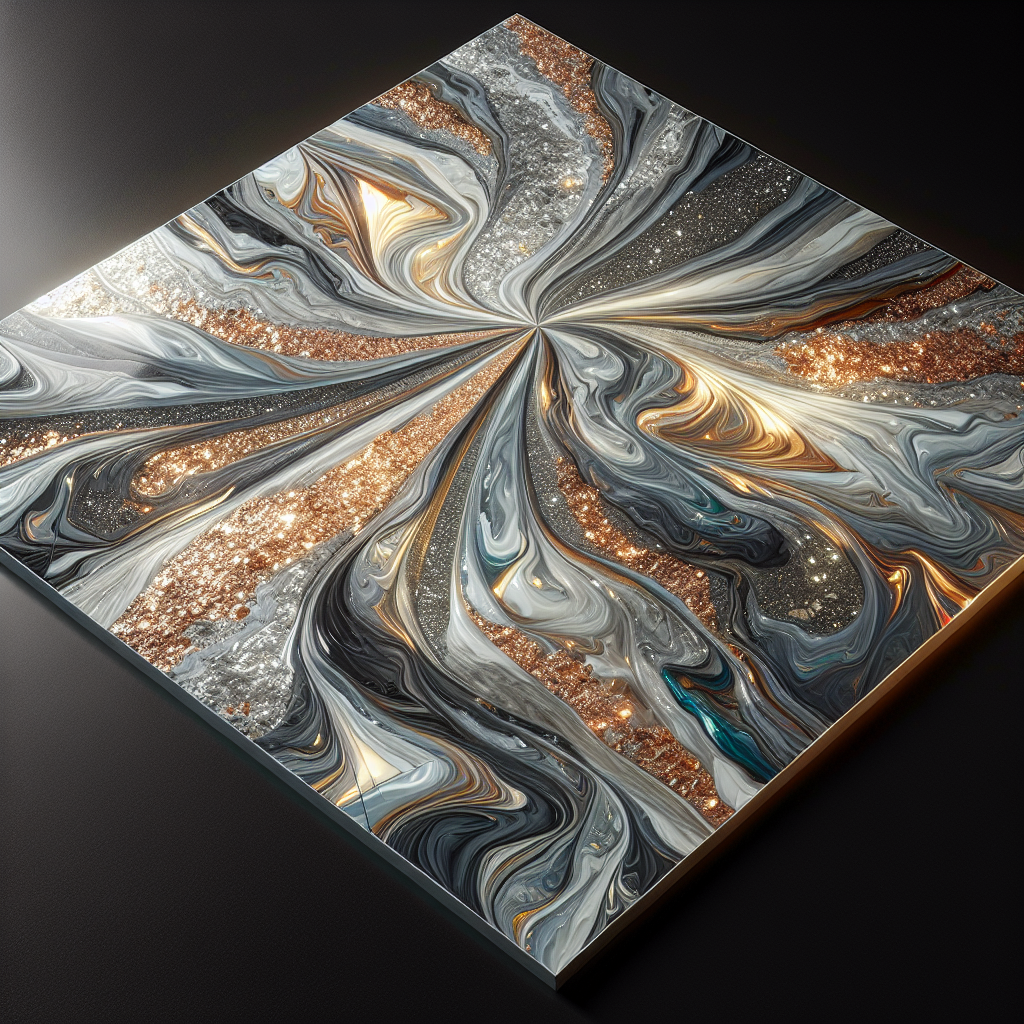

Metallic epoxy floors are gaining popularity for their remarkable advantages that appeal to both residential and commercial property owners. One of the most notable benefits is their stunning visual appeal. The metallic pigments mixed into the epoxy create a floor that boasts a high-gloss finish with a unique, three-dimensional effect, often resembling the look of polished stone or liquid metal. This makes it an ideal choice for those looking to make a bold statement in their interior design.

Beyond aesthetics, metallic epoxy floors are incredibly durable and long-lasting. They can withstand heavy foot traffic, resist abrasion, and are impervious to most chemicals and stains, making them a practical choice for both homes and businesses. This durability ensures that the floor maintains its appearance and functionality over time, reducing the need for frequent repairs or replacements.

Another significant advantage of metallic epoxy floors is their ease of maintenance. These floors are seamless, which means there are no grout lines or cracks where dirt and grime can accumulate. A simple regular cleaning routine involving sweeping and mopping is usually sufficient to keep them looking pristine. Furthermore, their non-porous nature helps in resisting moisture, making them suitable for environments prone to spills or humidity.

In summary, the combination of visual sophistication, durability, and low maintenance makes metallic epoxy floors an attractive option for those seeking a powerful blend of beauty and practicality in their flooring choice.

Potential Drawbacks of Epoxy Flooring

While metallic epoxy flooring offers numerous benefits, it’s important to consider some potential drawbacks before making a decision. One of the primary concerns is the initial cost. The installation of metallic epoxy floors can be more expensive compared to other flooring options, largely due to the specialized materials and labor-intensive application process involved. However, it’s essential to weigh these costs against the long-term durability and minimal maintenance they offer.

Another potential downside is the complex installation process. Achieving the desired metallic effect requires expertise and precision, often necessitating the services of a professional installer to ensure a flawless finish. Any errors during the application can result in imperfections that may be costly and time-consuming to correct.

Furthermore, although metallic epoxy floors are known for their durability, they can be prone to scratching and chipping under certain conditions. Heavy impacts or dragging sharp objects across the surface can cause damage that detracts from their aesthetic appeal. To mitigate this, it’s advisable to use floor mats in high-traffic areas and take precautions when moving heavy items.

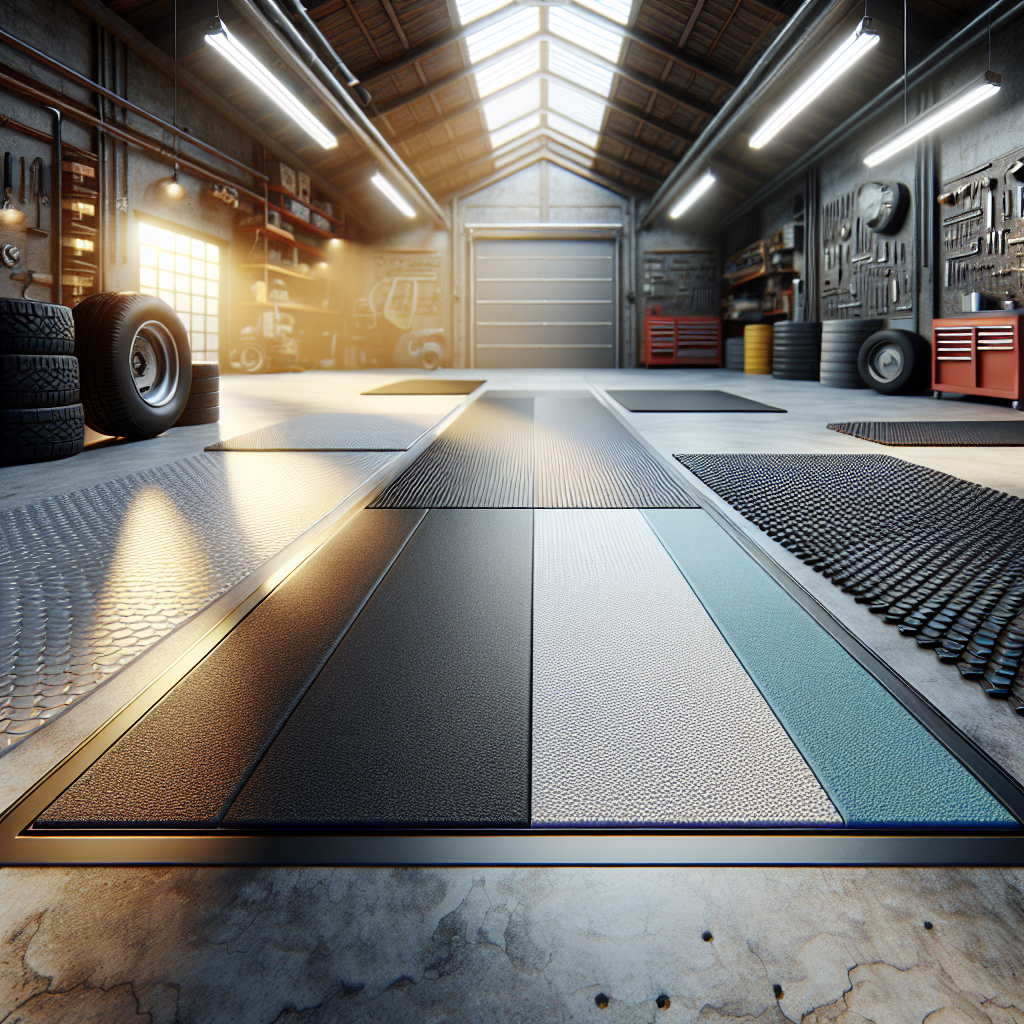

Finally, while these floors are generally low-maintenance, they can become slippery when wet, posing a potential hazard. To address this, anti-slip additives can be incorporated into the epoxy mix during installation, or anti-slip mats can be placed in areas prone to moisture.

Understanding these potential drawbacks enables property owners to make an informed decision and take proactive measures to maximize the benefits of their metallic epoxy flooring investment.

Installation Process of Metallic Epoxy

The installation process of metallic epoxy flooring is a meticulous and multi-step procedure that demands attention to detail and expertise to achieve the desired stunning visual effect. The process begins with **surface preparation**, which is crucial for ensuring proper adhesion. This involves cleaning the existing floor thoroughly to remove any dirt, grease, or debris, followed by grinding or shot blasting to create a roughened surface profile.

Once the surface is adequately prepared, the next step is to apply a primer coat. This layer serves as a bonding agent between the floor and the epoxy, enhancing the adhesion and longevity of the flooring system. After the primer has cured, the metallic epoxy mixture is meticulously prepared by blending epoxy resin with metallic pigments. This mixture is then poured onto the floor and spread evenly using a squeegee or roller.

The creative aspect of the installation comes into play during the design phase, where the installer uses various tools and techniques to create the desired patterns and effects. This may involve swirling, streaking, or feathering the metallic pigments to achieve a unique and dynamic appearance.

After the design is complete, the floor is left to cure, which can take anywhere from 24 to 48 hours, depending on environmental conditions and the specific epoxy formulation used. Once cured, a topcoat is applied to seal and protect the surface, enhancing its durability and resistance to stains and scratches.

The entire installation process can take several days, but the result is a striking, durable, and low-maintenance floor that transforms any space into a work of art.

Maintenance Tips for Epoxy Floors

Maintaining your metallic epoxy flooring is essential to preserve its aesthetic appeal and durability over time. Thankfully, the maintenance process is relatively straightforward, making epoxy floors an excellent choice for both residential and commercial spaces.

First and foremost, regular sweeping and dust mopping are recommended to prevent dirt and debris from accumulating. These particles can act like abrasives underfoot and potentially dull the glossy finish of the floor. Using a soft-bristle broom or a microfiber dust mop is ideal for this task.

For more thorough cleaning, use a mild, non-abrasive cleaner mixed with warm water. Avoid harsh chemicals or acidic cleaners, as they can damage the epoxy surface over time. A simple mop or a soft cloth can be used to wipe the floor, ensuring to rinse it well to remove any soap residue. **Stains** should be addressed promptly with gentle cleaning techniques to prevent them from setting.

To maintain the floor’s glossy finish, periodic application of a suitable floor polish can be beneficial. This not only enhances the shine but also provides an extra layer of protection against scratches and marks.

It’s also crucial to protect the floor from heavy impacts and sharp objects, as these can cause chips or scratches. Consider using floor mats or pads under furniture legs to minimize potential damage. Additionally, while epoxy floors are quite durable, keeping an eye out for any signs of wear or damage and addressing them promptly can significantly extend the floor’s lifespan.

By following these simple maintenance tips, your metallic epoxy floor can remain a stunning and functional feature of your space for many years.

Conclusion: Is Metallic Epoxy Right for You

After exploring the pros and cons of metallic epoxy flooring, it is clear that this flooring option offers a unique blend of aesthetic appeal and durability. Its striking finish and ability to withstand heavy foot traffic make it an attractive choice for those seeking both beauty and functionality in their flooring.

However, as with any flooring solution, there are considerations to keep in mind. The installation process requires professional expertise to achieve the desired effect, and while maintenance is relatively simple, it demands regular attention to retain its glossy appearance. Furthermore, initial installation costs can be higher compared to some other flooring options, but the long-term benefits often justify the investment.

Ultimately, whether metallic epoxy flooring is right for you depends on your specific needs and preferences. If you are drawn to its visual appeal and are committed to maintaining its pristine condition, it certainly stands out as a compelling option.

If you’ve decided that metallic epoxy flooring meets your criteria, or if you have further questions about its suitability for your space, we are here to help. Call Us Today for a Free Quote and let us guide you through the process of transforming your flooring with expert precision and care.