If you are looking to enhance the beauty and longevity of your floors, then you need to consider the services offered by a B&B floor polishing specialist. These professionals are equipped with the expertise and tools necessary to transform your floors from dull and worn to shiny and pristine. Whether you own a bed and breakfast, a hotel, or even a private residence, the right floor polishing can make a significant difference in the overall aesthetic and feel of your space.

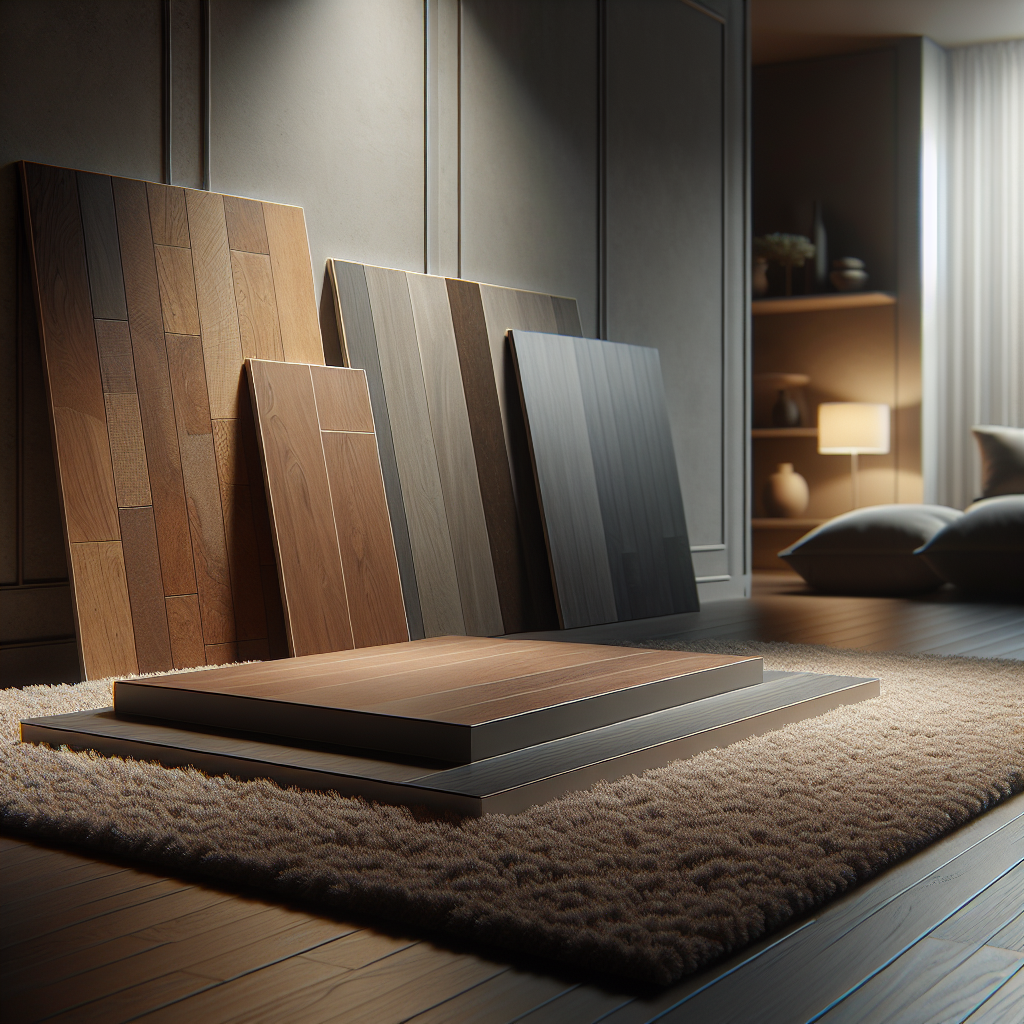

Floor polishing not only improves the appearance of your surfaces but also extends their lifespan by protecting them from wear and tear. A B&B floor polishing specialist will assess your flooring type—be it hardwood, marble, or concrete—and apply the appropriate techniques and products to achieve optimal results. Here are some benefits of hiring a professional:

- Expertise: Specialists have the knowledge to choose the right polishing method and products.

- Quality Results: Professional equipment ensures a higher quality finish compared to DIY methods.

- Time-Saving: Professionals work efficiently, saving you valuable time.

With the right service, your floors can become a stunning focal point that impresses your guests and enhances their experience. Call Us Today for a Free Quote and discover how our B&B floor polishing specialist services can give your floors the care they deserve.

Understanding the Importance of Professional Floor Polishing

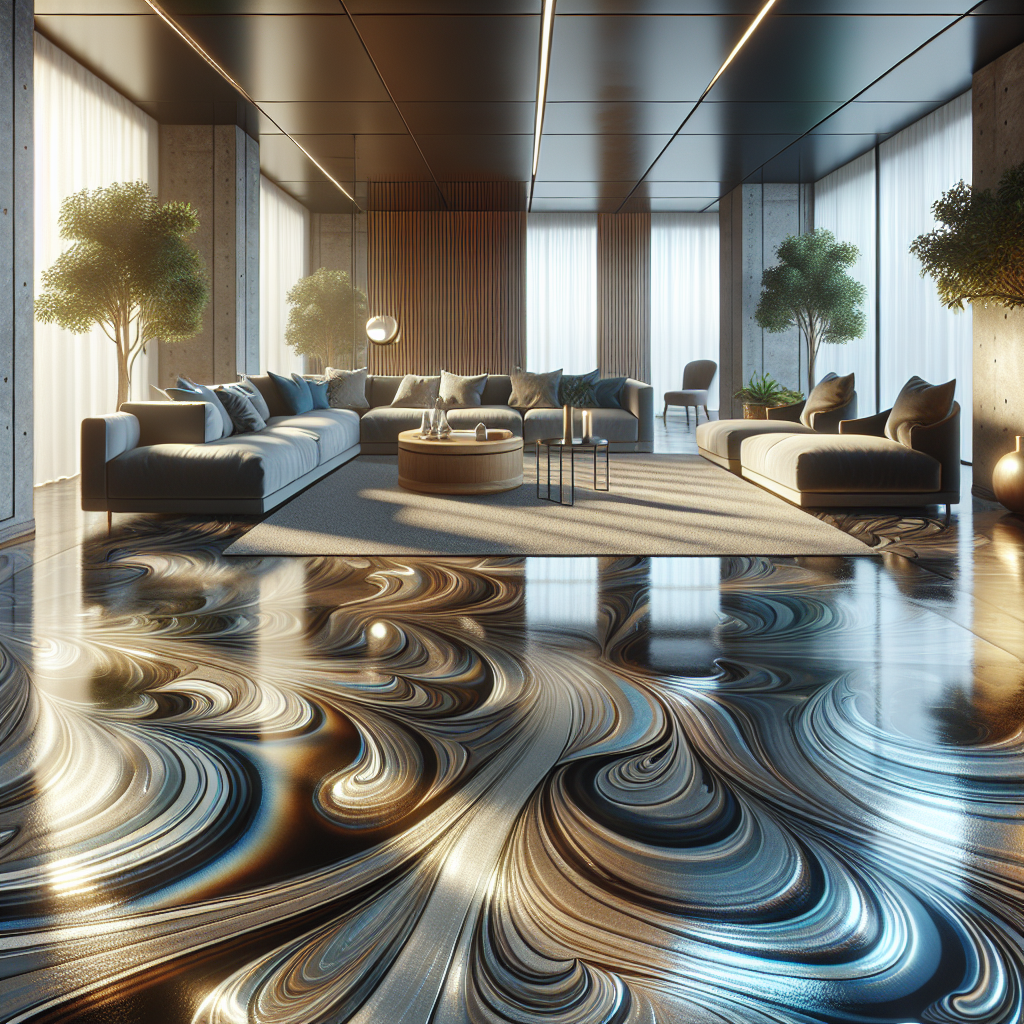

Understanding the significance of professional floor polishing is essential for anyone looking to maintain and enhance the quality of their flooring. Floors are one of the most prominent features in any establishment, and their condition can greatly influence the first impression on guests or clients. Over time, floors can accumulate dirt, scratches, and wear, leading to a dull appearance that detracts from the overall ambiance of a space.

Here are some key reasons why investing in professional floor polishing is crucial:

- Enhanced Aesthetics: A well-polished floor can dramatically improve the visual appeal of a room, making it more inviting and attractive.

- Increased Durability: Polishing helps protect the floor surface, minimizing damage and wear, which prolongs the life of the flooring material.

- Improved Hygiene: Floor polishing reduces the accumulation of dust and allergens, contributing to a cleaner and healthier environment.

- Safety: Smooth, polished floors are less likely to harbor slips and falls, making them a safer option for guests and residents.

By choosing a professional service, you ensure that the job is done correctly and efficiently, using the right techniques and equipment tailored to your specific flooring type. This expertise not only enhances the appearance of your floors but also supports their functionality and longevity.

Key Benefits of Hiring a B&B Floor Polishing Specialist

When it comes to maintaining the beauty and durability of your floors, hiring a B&B floor polishing specialist offers numerous advantages that can significantly enhance your property. Here are some of the key benefits that come from enlisting the expertise of these professionals:

- Expert Knowledge: B&B floor polishing specialists possess extensive knowledge of various flooring materials, enabling them to select the appropriate polishing techniques and products that will yield the best results for your specific floor type.

- Professional Equipment: These specialists utilize advanced equipment and tools that are designed for effective floor polishing, ensuring a high-quality finish that is difficult to achieve with standard household cleaning tools.

- Time Efficiency: Hiring a professional allows you to save time. Instead of dedicating hours or even days to floor maintenance, you can focus on other important tasks while the specialists handle the polishing.

- Consistent Results: With their experience, B&B floor polishing specialists can deliver uniform results across your floors, avoiding unsightly patches or uneven surfaces that might occur with DIY efforts.

- Long-term Cost Savings: Regular professional polishing can help extend the lifespan of your floors, reducing the need for costly repairs or replacement in the future.

Investing in the services of a B&B floor polishing specialist not only enhances the appearance of your floors but also provides peace of mind, knowing that your property is in capable hands.

What to Look for in a Floor Polishing Specialist

Choosing the right floor polishing specialist can make all the difference in achieving the desired finish and longevity for your floors. Here are some essential factors to consider when selecting a professional:

- Experience and Expertise: Look for specialists with a proven track record in floor polishing. A contractor with substantial experience will be more adept at handling various types of flooring and addressing any unique challenges that may arise.

- Reputation and Reviews: Research online reviews and testimonials from previous clients. A reputable specialist will often have a portfolio of their work and positive feedback that showcases their commitment to quality.

- Range of Services: Ensure that the specialist offers comprehensive services tailored to your specific needs, including surface preparation, sealing, and maintenance options for your floors.

- Quality of Equipment: Inquire about the tools and products the specialist uses. Advanced and well-maintained equipment often leads to better results and a more efficient polishing process.

- Transparent Pricing: Request detailed quotes that outline the costs involved. A trustworthy specialist will provide clear pricing without hidden fees, allowing you to budget effectively for the service.

By carefully considering these aspects, you can find a reliable floor polishing specialist who will not only enhance the look of your floors but also ensure their durability and longevity.

Common Techniques Used by Floor Polishing Experts

Floor polishing experts utilize a variety of techniques to achieve a pristine finish that enhances both the beauty and durability of your floors. Understanding these methods can help you appreciate the craftsmanship behind professional floor care. Here are some common techniques employed by specialists:

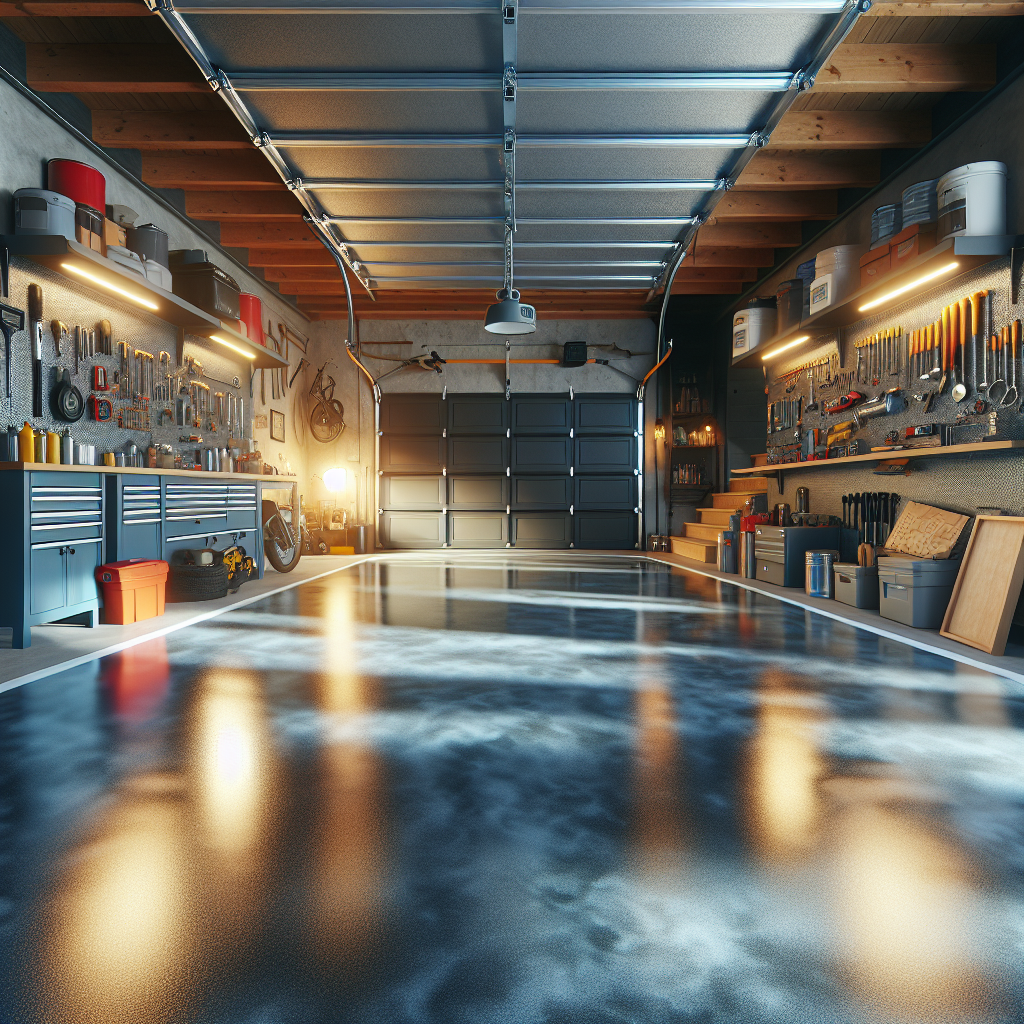

- Diamond Grinding: This method involves using diamond-embedded pads to grind down the surface of the floor, effectively removing imperfections and preparing it for polishing. It’s particularly effective for concrete and terrazzo floors.

- Buffing: Buffing is a technique that involves using a high-speed buffing machine to polish the surface of the floor. This process helps to create a glossy finish and enhances the floor’s appearance, making it look brand new.

- Honing: Often used for natural stone floors, honing involves grinding the surface with finer abrasives to create a smooth, matte finish. This technique is ideal for surfaces that require a less shiny appearance while still looking refined.

- Coating: After polishing, applying a protective coating can significantly increase the longevity of the floor’s finish. Sealants or waxes are often used to protect against stains and wear, ensuring that the polished look lasts longer.

- Spot Treatment: For floors with specific stains or blemishes, professionals may employ targeted treatments to remove these imperfections without the need for full floor resurfacing.

Each of these techniques can significantly enhance the appearance and durability of your floors, making it essential to work with a qualified floor polishing expert who can select the best method tailored to your flooring type and condition.

Conclusion: Choosing the Right B&B Floor Polishing Specialist

When it comes to maintaining and enhancing the beauty of your floors, selecting the right B&B floor polishing specialist is crucial. With various options available, you want to ensure that you choose a professional who not only understands the intricacies of floor polishing but also has a proven track record of delivering exceptional results.

Start by researching local specialists, checking their reviews, and asking for references. It’s vital to inquire about the specific techniques they use, as well as their experience with different flooring materials. A knowledgeable specialist will be able to provide tailored solutions that meet your unique needs.

Furthermore, consider their certifications and insurance, as these factors reflect their professionalism and commitment to quality service. A reputable floor polishing expert will be transparent about their processes and will work with you to achieve the best possible outcome for your floors.

Ultimately, investing in a skilled B&B floor polishing specialist can dramatically transform your space, enhancing not only the aesthetics but also the longevity of your flooring. Call Us Today for a Free Quote and let Americas Industrial Coatings in Fort Lauderdale help you achieve the perfect finish for your floors!