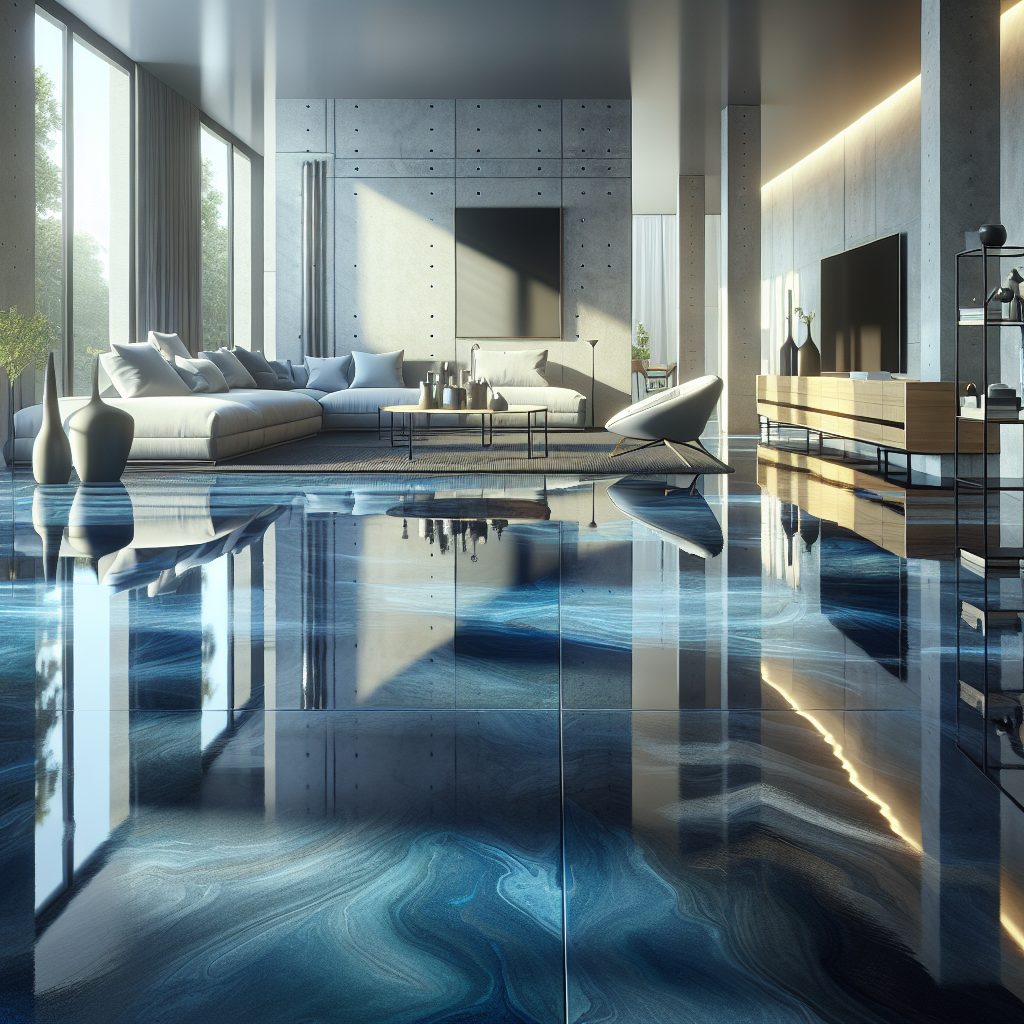

When it comes to understanding epoxy flooring, it’s essential to delve into its composition and the factors that contribute to its remarkable durability. Epoxy is a resinous material formed through a chemical reaction between an epoxy resin and a hardener. This unique combination creates a robust, protective surface that is ideal for various applications, including garages, warehouses, and commercial spaces.

The durability of epoxy flooring can be attributed to several factors:

- Resistance to Chemicals: Epoxy flooring is highly resistant to a wide array of chemicals, making it suitable for environments where spills may occur, such as in automotive or manufacturing facilities.

- Impact Resistance: The hardened surface of epoxy can withstand heavy impacts and prevent chipping or cracking, which is crucial for high-traffic areas.

- Low Maintenance: Once installed, epoxy floors require minimal maintenance compared to other types of flooring. Regular cleaning is usually sufficient to keep them looking new.

- Longevity: With proper installation and care, epoxy flooring can last for many years, even under challenging conditions.

The installation process also plays a vital role in achieving the optimal durability of epoxy floors. Ensuring a proper substrate preparation and application technique is key. For professional results, it’s advisable to rely on experts who understand the intricacies of this flooring system.

Call Us Today for a Free Quote on your epoxy flooring installation needs and discover how this durable solution can transform your space!

Factors That Influence Epoxy Flooring Hardness

The hardness of epoxy flooring is not a one-size-fits-all characteristic; it is influenced by several key factors that determine its performance and durability. Understanding these factors can help you choose the right epoxy solution for your specific needs.

Here are some of the primary factors that influence the hardness of epoxy flooring:

- Type of Epoxy Resin: Different formulations of epoxy resin can affect the final hardness of the floor. High-performance epoxies often have enhanced hardness properties compared to standard formulations.

- Hardener Ratio: The ratio of resin to hardener during the mixing process is crucial. A higher hardener ratio typically results in a harder finish, while a lower ratio may yield a softer surface.

- Temperature During Installation: Ambient temperature and surface temperature can significantly impact the curing process. Higher temperatures can accelerate curing and enhance hardness, while lower temperatures may slow it down and lead to a softer finish.

- Thickness of the Application: The thickness of the epoxy layer applied can also determine its hardness. A thicker application generally leads to a more durable and harder surface.

- Environmental Conditions: Humidity and air circulation during the curing phase can influence the final hardness of the floor. Excess moisture can weaken the bond and result in a less durable surface.

By considering these factors, you can better understand how to achieve the optimal hardness and durability of your epoxy flooring, ensuring it meets the demands of your environment.

Comparing Epoxy Flooring to Other Flooring Options

When considering flooring options, it’s essential to weigh the advantages and disadvantages of various materials against your specific needs. Epoxy flooring stands out in comparison to other popular flooring choices, such as concrete, vinyl, and tile, primarily due to its unique properties and benefits.

Here’s a comparison of epoxy flooring with other common flooring materials:

- Epoxy vs. Concrete: While concrete is durable, it is susceptible to stains and damage without proper sealing. Epoxy flooring provides a seamless, stain-resistant surface that is easier to clean and maintain, offering enhanced durability and aesthetics.

- Epoxy vs. Vinyl: Vinyl flooring is known for its comfort and affordability but often lacks the hardness and durability of epoxy. Epoxy is more suitable for high-traffic areas and can withstand harsh chemicals, making it ideal for commercial and industrial settings.

- Epoxy vs. Tile: Tile flooring can be beautiful and versatile, but it may require grout maintenance and is prone to cracking. Epoxy flooring offers a smooth, continuous surface without grout lines, reducing maintenance and improving cleanliness.

In summary, when comparing epoxy flooring to other options, it’s clear that epoxy provides superior durability, ease of maintenance, and aesthetic versatility. Its unique properties make it a top choice for both residential and commercial applications.

Installation Process of Epoxy Flooring Explained

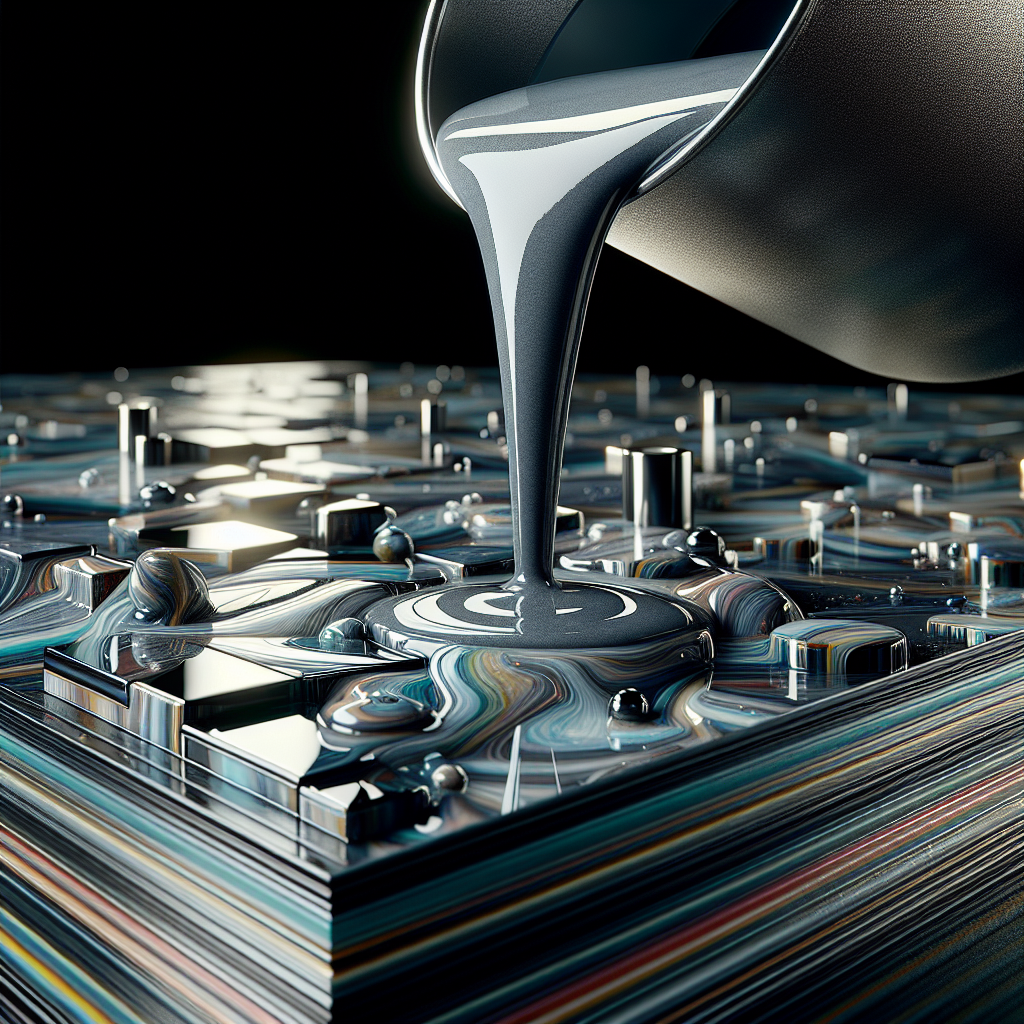

The installation process of epoxy flooring is a crucial step that ensures the longevity and effectiveness of the final product. Understanding this process can help you prepare for what to expect and ensure a successful outcome.

Here’s a detailed breakdown of the typical steps involved in installing epoxy flooring:

- Surface Preparation: The first step is thorough surface preparation. This includes cleaning the floor to remove any dust, dirt, or debris, as well as repairing any cracks or imperfections. A well-prepared surface is essential for proper adhesion.

- Grinding or Shot Blasting: Depending on the existing floor condition, it may be necessary to grind or shot blast the surface to create a profile that allows the epoxy to bond effectively. This step ensures that the epoxy adheres properly and reduces the risk of peeling or bubbling.

- Application of Primer: Once the surface is prepared, a primer is applied. This layer enhances the bonding of the epoxy and can also help to seal any porous areas in the substrate.

- Mixing the Epoxy: The epoxy resin and hardener are mixed according to the manufacturer’s instructions. Proper mixing is vital to achieve the desired chemical reaction that results in a hard and durable surface.

- Applying the Epoxy Coating: After mixing, the epoxy is applied using rollers or squeegees. Depending on the desired thickness and finish, multiple layers may be applied, with appropriate curing times in between.

- Finishing Touches: Finally, once the epoxy has cured, any necessary finishing touches, such as adding decorative flakes or a topcoat, can be performed to enhance aesthetics and durability.

Completing the installation process correctly is vital for obtaining a high-quality epoxy floor that withstands the test of time and usage. A professional installation team, like the experts at Americas Industrial Coatings, can ensure that every step is executed flawlessly, leading to a stunning and durable flooring solution.

Maintaining Epoxy Flooring for Longevity

To maximize the lifespan of your epoxy flooring, regular maintenance is essential. Proper care not only helps maintain its aesthetic appeal but also enhances its durability and performance. Here are some effective maintenance tips to ensure your epoxy floors remain in top condition:

- Regular Cleaning: Dust, dirt, and debris can accumulate on the surface of your epoxy floor, potentially leading to scratches or dullness. Regularly sweeping or vacuuming the floor will help keep it clean. For deeper cleaning, damp mopping with a mild detergent solution will effectively remove stubborn stains and grime.

- Avoid Harsh Chemicals: While epoxy floors are resistant to many substances, using harsh chemicals or abrasive cleaners can damage the surface. It is advisable to use pH-neutral cleaners specifically designed for epoxy flooring.

- Prompt Spill Cleanup: Epoxy flooring is resistant to chemicals, but it is still wise to clean spills promptly. This prevents any potential staining or damage. Use a soft cloth or paper towel to absorb spills and then clean the area with a suitable cleaner.

- Inspect and Repair: Regular inspections can help you identify any signs of wear or damage early. If you notice any cracks or peeling, address them immediately to prevent further deterioration. Small repairs can often be made without the need for a complete floor overhaul.

- Resealing Periodically: Depending on the level of foot traffic and usage, resealing your epoxy flooring every few years can provide additional protection and restore its shine. Consult with a professional for the best sealing products and techniques.

By following these maintenance tips, you can ensure that your epoxy flooring stays vibrant and functional for many years to come. This proactive approach will not only save you money on repairs but also enhance the overall appearance of your space.

Common Myths About Epoxy Flooring Hardness

When it comes to epoxy flooring, several misconceptions can lead to confusion about its hardness and durability. Understanding the facts can help you make informed decisions when considering epoxy flooring for your space. Here are some common myths debunked:

- Myth: Epoxy Flooring is Too Soft: Many believe that epoxy flooring lacks the hardness needed for high-traffic areas. In reality, epoxy is highly durable and can withstand heavy loads, making it suitable for garages, warehouses, and industrial facilities.

- Myth: Epoxy Floors Are Prone to Cracking: Some assume that because epoxy is a thin coating, it is vulnerable to cracks. However, when properly installed and maintained, epoxy floors are designed to handle stress and impact without cracking.

- Myth: All Epoxy Floors are the Same: There is a misconception that all epoxy flooring materials offer the same level of hardness and durability. In fact, the quality of resin and proper preparation during installation greatly affect the final product’s strength.

- Myth: Epoxy Flooring is Not Slip-Resistant: Another common belief is that epoxy flooring is slippery. While it can be, adding anti-slip additives during installation can significantly enhance traction, making it safe for various environments.

- Myth: Epoxy Floors Require Extensive Maintenance: Some people think that maintaining epoxy flooring is overly complicated. In truth, with regular cleaning and occasional resealing, epoxy floors are relatively low-maintenance.

Dispelling these myths can help you appreciate the true value of epoxy flooring. Its hardness and durability make it a fantastic choice for many applications. If you’re considering installing epoxy flooring or have more questions about its benefits, Call Us Today for a Free Quote at Americas Industrial Coatings in Fort Lauderdale!