When considering new flooring options, it’s essential to gather as much information as possible. Pal Flooring has gained attention in the market, and for good reason. In this section, we will delve into the Pal Flooring review, exploring the various aspects you need to know before making a decision. Understanding the features, benefits, and potential drawbacks of Pal Flooring will empower you to make an informed choice that suits your space and lifestyle.

Reviews can provide valuable insights into the experiences of other customers. Here are some key points to consider:

- Durability: How well does Pal Flooring hold up under daily wear and tear?

- Design Options: What styles and colors are available to fit your aesthetic?

- Installation Process: Is it user-friendly for DIY projects or does it require professional help?

- Cost Effectiveness: Does the price reflect the quality and longevity of the flooring?

In our subsequent sections, we will provide an in-depth analysis of these key attributes, allowing you to weigh the pros and cons effectively. Call Us Today for a Free Quote to learn more about your flooring options and how Pal Flooring could be a great choice for your home or business.

Key Features of Pal Flooring Explained

Understanding the key features of Pal Flooring is crucial for evaluating its suitability for your needs. This flooring option is designed to provide both aesthetic appeal and functional benefits, making it a popular choice among homeowners and businesses alike. Here are some of the standout features that set Pal Flooring apart:

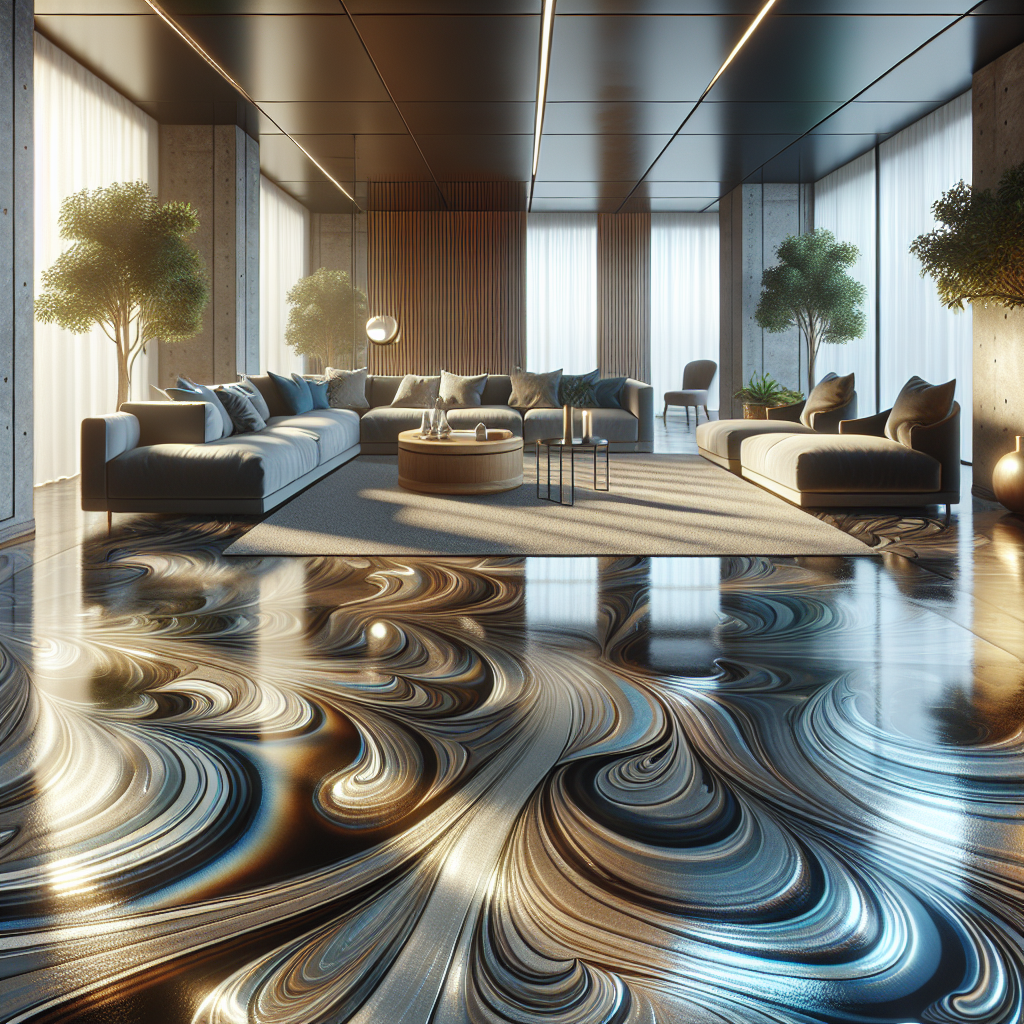

- Variety of Styles: Pal Flooring comes in a diverse range of colors and designs, allowing you to find the perfect match for your interior decor. Whether you prefer a classic hardwood look or a modern tile design, there’s something for everyone.

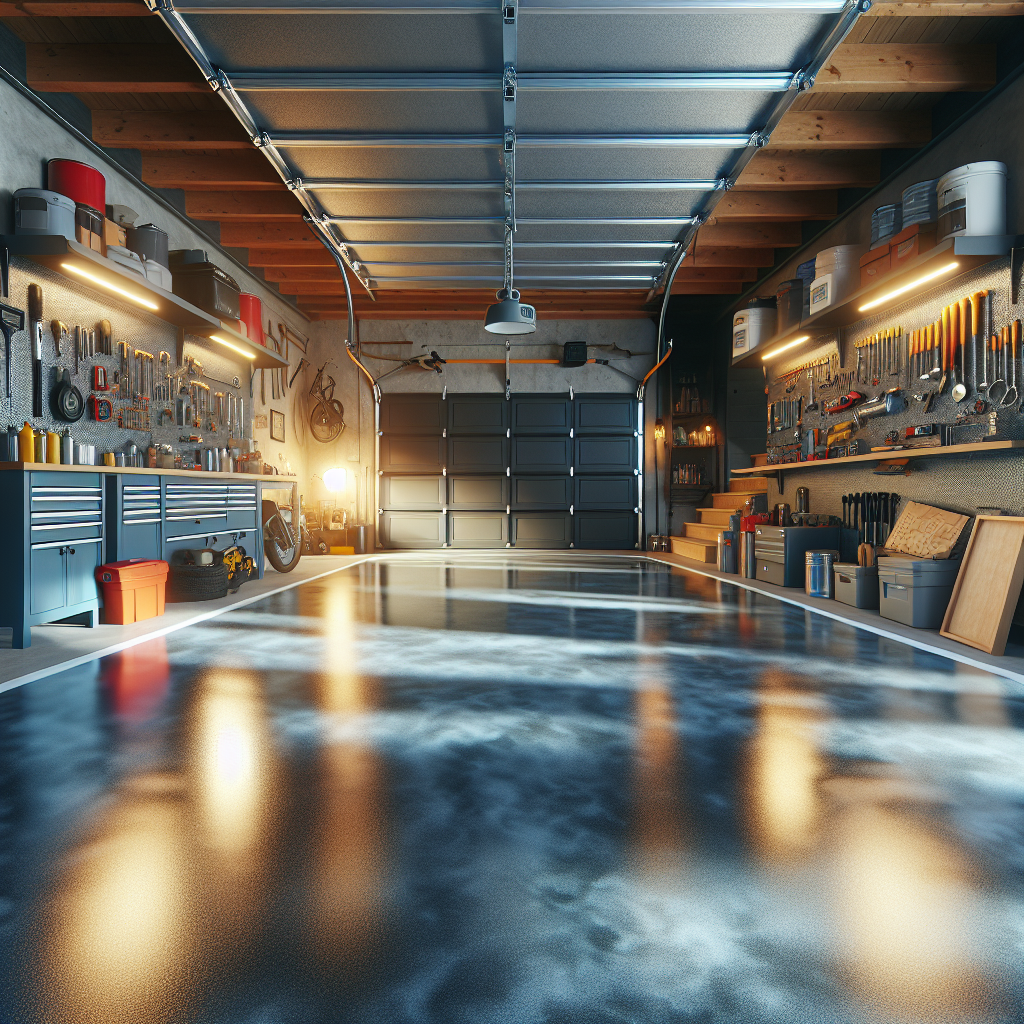

- Durability: Known for its robust construction, Pal Flooring is engineered to withstand heavy foot traffic and resist scratches and scuffs. This makes it an excellent choice for both residential and commercial spaces.

- Easy Maintenance: One of the advantages of Pal Flooring is its low-maintenance nature. Regular sweeping and occasional mopping are usually enough to keep it looking pristine, saving you time and effort.

- Comfort: Many users report that Pal Flooring provides a comfortable underfoot feel, making it pleasant to walk on for extended periods.

- Eco-Friendly Options: For environmentally conscious consumers, Pal Flooring offers sustainable choices made from recycled materials, ensuring that you can achieve your flooring goals while being kind to the planet.

These features contribute to the overall appeal of Pal Flooring, making it a worthy consideration for anyone looking to upgrade their flooring. As we continue to explore the pros and cons, understanding these key aspects will help you make a more informed decision.

Pros and Cons of Choosing Pal Flooring

When considering any flooring option, it’s essential to weigh the pros and cons. Pal Flooring is no exception, as it comes with its unique set of advantages and disadvantages that can impact your decision. Here’s a closer look:

- Pros:

- Affordability: Compared to traditional hardwood or stone floors, Pal Flooring is often more budget-friendly, making it accessible for various projects.

- Installation Ease: Many Pal Flooring products are designed for easy installation, even for DIY enthusiasts, which can save you additional labor costs.

- Versatile Design: Its wide array of styles allows you to customize your space easily, catering to different tastes and aesthetics.

- Resistant to Moisture: Pal Flooring typically performs well in areas prone to moisture, such as kitchens and bathrooms, reducing the risk of warping or damage.

- Cons:

- Limited Lifespan: While durable, Pal Flooring may not last as long as solid hardwood, which can be a consideration for long-term investments.

- Sound Absorption: Some users report that Pal Flooring can be noisier than carpet or other flooring types, which might not be ideal for every environment.

- Appearance Over Time: Depending on the quality, some Pal Flooring options can show wear and tear more quickly, affecting the visual appeal.

By understanding these pros and cons, you can better evaluate whether Pal Flooring fits your specific needs and preferences. This assessment will guide you as we dive deeper into the specifics of this flooring choice.

Comparing Pal Flooring with Other Brands

When choosing the right flooring for your space, it’s crucial to compare Pal Flooring with other brands to ensure you make an informed decision. Here’s how Pal Flooring stacks up against some popular alternatives:

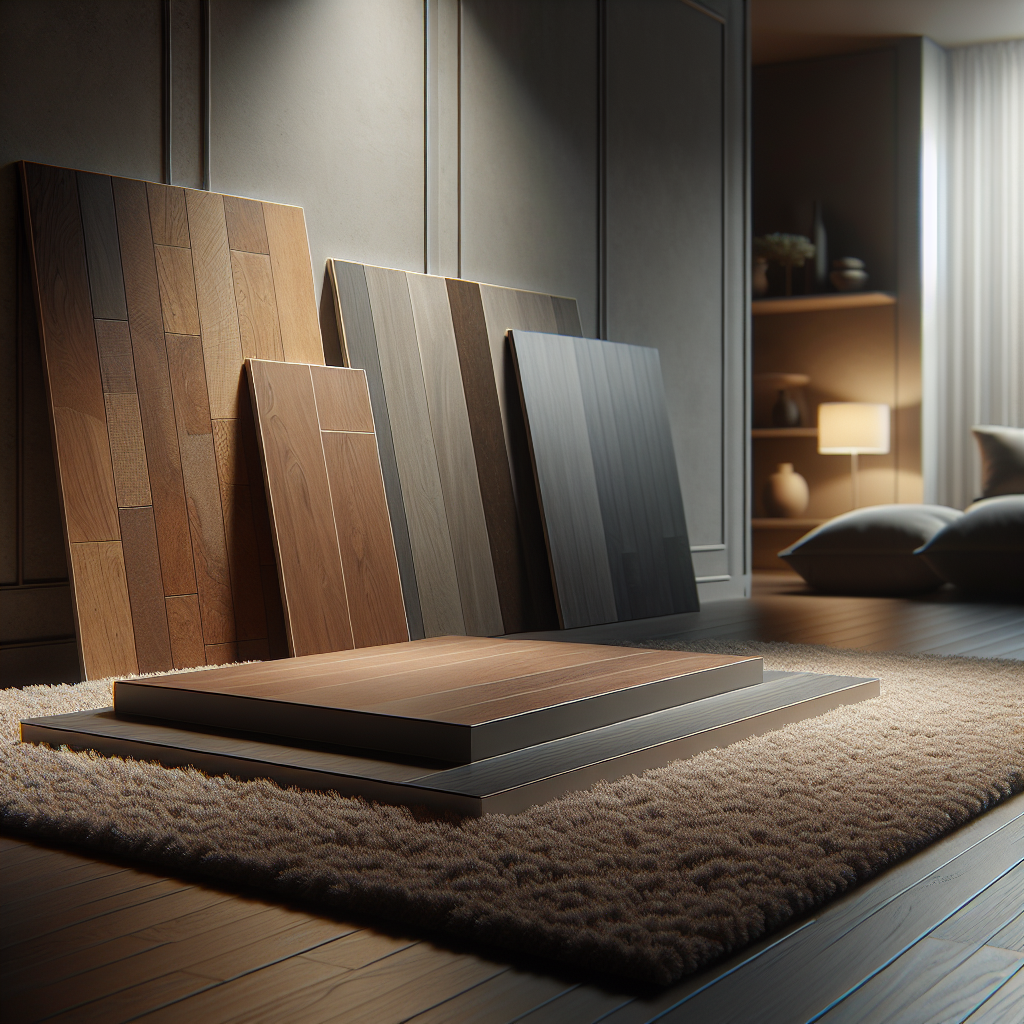

- Pal Flooring vs. Vinyl Flooring: While both options offer durability and easy maintenance, vinyl flooring often provides a wider range of design choices and is generally more resistant to scratches. However, Pal Flooring tends to be more affordable, making it a viable option for budget-conscious consumers.

- Pal Flooring vs. Laminate Flooring: Laminate flooring is known for its realistic wood appearance and affordability, similar to Pal Flooring. Yet, Pal Flooring is often favored for its moisture resistance, making it a better choice for rooms like kitchens and bathrooms.

- Pal Flooring vs. Hardwood Flooring: Solid hardwood is a classic choice known for its longevity and timeless appeal. However, it comes at a premium price. In contrast, Pal Flooring offers a budget-friendly alternative while still providing a stylish look. It is less likely to warp in humid environments, which can be a significant advantage.

- Pal Flooring vs. Carpet: Carpets provide warmth and comfort underfoot, ideal for bedrooms and living areas. However, they require more maintenance and can trap allergens. Pal Flooring, on the other hand, is easier to clean and more resistant to stains, making it a practical choice for high-traffic areas.

Ultimately, comparing Pal Flooring with other brands highlights its unique strengths and weaknesses. This understanding allows you to choose the flooring that best meets your lifestyle and aesthetic preferences.

Customer Feedback and User Experiences

Customer feedback plays a significant role in understanding the overall satisfaction with Pal Flooring. Reviews from users often highlight various aspects of their experiences, providing potential buyers with valuable insights.

Many customers appreciate the affordability of Pal Flooring, noting that it offers great value without compromising on quality. Affordability is a recurring theme in many testimonials, with users mentioning how they were able to achieve a high-end look at a fraction of the cost.

Another common positive remark is about the ease of installation. Numerous users have shared their experiences of a straightforward installation process. Whether they hired professionals or tackled the project as a DIY endeavor, the consensus is that Pal Flooring is user-friendly, which can significantly reduce labor costs.

However, some customers have reported issues related to durability. A few users mentioned that certain styles of Pal Flooring showed signs of wear and tear sooner than expected, particularly in high-traffic areas. This feedback is essential for potential buyers to consider, especially if they have pets or children in the household.

Additionally, customer service experiences have varied. While some customers have praised the responsiveness and helpfulness of the company, others have expressed frustration regarding delays in order fulfillment or warranty claims. This inconsistency in service can impact the overall satisfaction and should be taken into account when considering a purchase.

Overall, customer feedback and user experiences reveal a mixed bag of insights. While Pal Flooring is generally well-regarded for its affordability and ease of installation, potential buyers should weigh these positives against reported durability issues and customer service experiences.

Final Thoughts on Pal Flooring for Homeowners

When it comes to choosing flooring for your home, Pal Flooring presents a compelling option for many homeowners. Its affordable pricing and ease of installation make it an attractive choice for those looking to enhance their living spaces without breaking the bank. Many users have expressed satisfaction with the aesthetic appeal of Pal Flooring, noting how it can transform a room with its stylish designs.

However, as with any product, it is crucial to consider both the pros and cons. While the majority of feedback highlights its affordability and installation ease, some concerns regarding durability cannot be overlooked. Homeowners should assess their specific needs—particularly in high-traffic areas—before making a decision.

Additionally, customer service experiences can vary, which may influence your overall satisfaction with the product. It is advisable to do thorough research and read multiple reviews to get a balanced perspective.

For homeowners who prioritize style, budget, and ease of installation, Pal Flooring could be a suitable choice. Ultimately, weighing all the factors against your unique needs will guide you toward making an informed decision.

Call Us Today for a Free Quote to explore how Americas Industrial Coatings can assist you in choosing the right flooring solution for your home!